Fixture of wall panels is carried out in two ways:

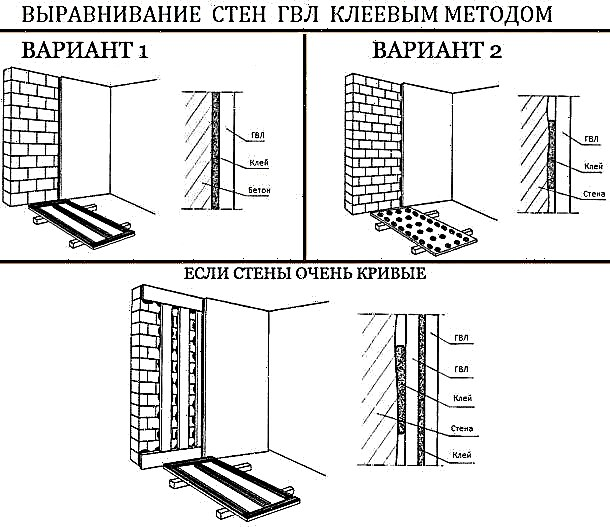

The frameless method involves the use of special glue, the type and quantity of which are determined depending on the quality of the wall and the presence of bumps. If there are no significant defects on the surface, gypsum adhesive is applied to the material, after which the sheet is pressed against the wall.

In the case when it is planned to work with surfaces on which there are significant irregularities, it will be necessary to apply a strong adhesive mixture to the entire base of the sheet. For better adhesion, you will additionally need to perform spot application - every 30-40 cm. You should also increase the amount of adhesive applied, if then it is supposed to fix hangers or shelves on the walls, which put an additional load.

Installation of GVL on walls can be done using frame or frameless methods.

The presence of the frame will help increase the strength of any surface and increase the ability of the wall to withstand increased loads. The advantage of the carcass is also the fact that between the sheet and the wall you can neatly lay a layer of insulation or soundproofing material.

With the help of GVL panels, many also carry out boxes in which you can neatly place electrical wiring, plumbing pipes and other communication systems. The sheets are fastened to the frame by means of special self-tapping screws, characterized by a double-row thread.

List of recommendations to avoid major mistakes:

- no need to chamfer before puttying,

- Do not use anything other than a double-threaded screw for GVL,

- between the sheets it is better to leave gaps whose thickness is equal to half the thickness of the plate,

- all cracks are filled with gypsum mixture or special glue,

- Before working with the surface, it is necessary to carry out a thorough treatment, eliminate all irregularities and prime the base.

Classification and specifications. Marking

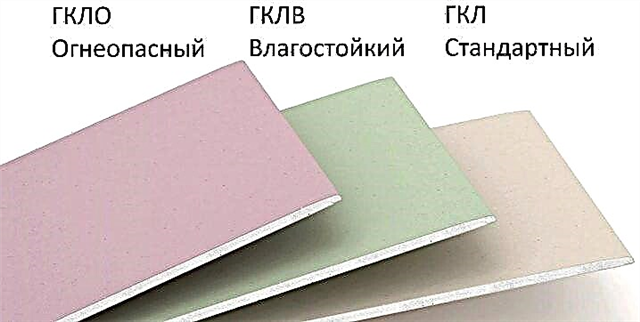

HLV plates are divided into standard (HLV) and moisture resistant (HLV).

The former are well suited for interior decoration of industrial and residential premises, in which the normal temperature and enough dry air.

Moisture-resistant sheets are treated with a hydrophobic solution, thanks to which they can be effectively used in all wet rooms (kitchen, toilet, bathroom), as well as in attics, basements, garages and many other construction objects.

Both standard and moisture resistant gypsum boards have a rectangular shape.

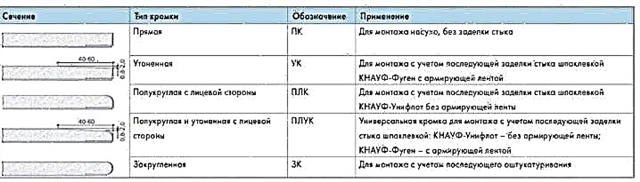

They can be direct (PC)

And seam (FC) edges.

GVLV types and marking

Gypsum fiber has one main difference - size. But it can also differ in the shape of the edge. That is why they are divided into two types.

| Having a straight edge (PC). | This type is suitable for laying floors. |

| Having a fold edge (FC). | They are used in wall and ceiling cladding, in the construction of partitions, piers. |

Sheets are divided into two types of PC and FC

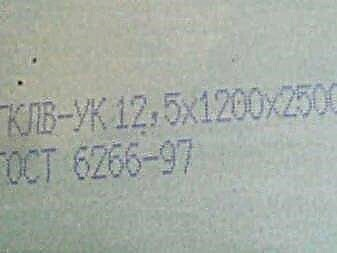

It is possible to distinguish which border of the material by its appearance, the rest of the data is indicated in the form of marking, applied on the reverse side. How to understand what is indicated there? First they print what type of gypsum fiber is - simply GVL or moisture-resistant GVLV. Then the accuracy of production is indicated, as well as a group of the type (“A” or “B”). Here you can immediately understand that the group A gypsum fiber is more accurate. After indicate the type of edge (FC or PC), sheet size, its standard.

You can distinguish between types of sheets by marking and material

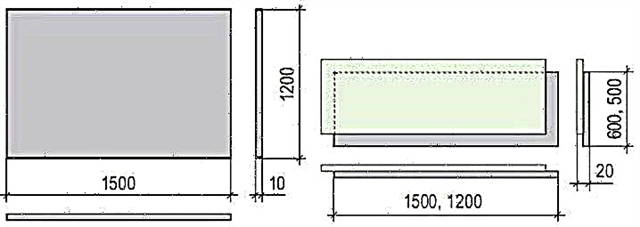

Here is one example of marking: GVL-A-PK-2500h1200h10 TU 5742-004-03515377-97. Means that this is an ordinary gypsum fiber for the floor, belongs to the first group of accuracy. Its size is 2500x1200 mm, sheet thickness 10 mm. Another sample: GVLV-B-FK-3000x1000x15 TU 5742-004-03515377-97. Means that this GVL moisture resistant for walls, belongs to the second group of accuracy. Its size is 3000x1000 mm, sheet thickness 15 mm.

The sheet size is indicated on the label.

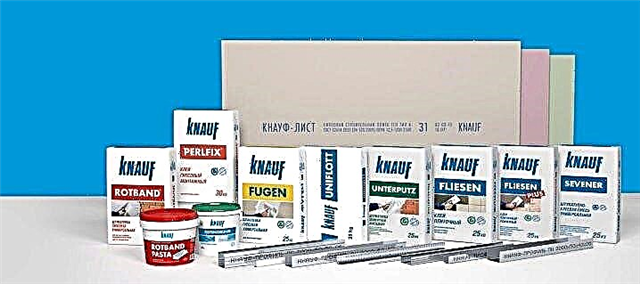

Overview of GKL and GVL of Knauf firm

Knauf gypsum sheets and gypsum plasterboards are very popular for wall decoration. They are also used for decoration of industrial buildings, residential interiors and public buildings. But since the building materials market is highly likely to stumble upon a fake, you should always familiarize yourself with the Knauf GKL certificates of conformity that every decent seller should have.

Plasterboard and gypsum fiber sheets from this manufacturer have a different structure.

The difference is determined in operational and technical characteristics:

- gypsum fiber has a smooth structure, which allows you to cut material without chips. Therefore, GVL can be used for parts of different sizes,

- use of GVL is required where high resistance to blows is necessary,

- drywall is characterized by excellent ductility, which allows you to make structures of different shapes from it,

- GVL and GKL of this company are also distinguished by the degree of frost resistance. At the same time, drywall is designed for 4 cycles of thawing and freezing, and gypsum fiber for 15 cycles.

The table below shows the approximate prices for different types of GVL and GKL from Knauf:

| Photo | Kinds | Description | Prices, rub. |

| GVL sheet Knauf floor element | 200 × 600x1200 mm. Super floor | 337 | |

| Knauf superlist gvl | 2500 × 1200. With a straight edge. | 487 | |

| Knauf gypsum plasterboard | 300 × 1200x12.5 mm Used for the construction of light partitions. | 279 | |

| Knauf GKL moisture resistant | 2500 × 1200. It is used for false ceilings and as a covering for walls. | 336 |

Knauf GCRKnauf GKL moisture resistant

Product specifications and sizes

Consider the main dimensions of the sheet GKL "Knauf":

| Kinds | Dimensions |

| Standard, 12.5 mm thick, 2 meters long. | 1200×2000 |

| Thickness 12.5, length 2.5 meters. | 1200×2500 |

| Thickness 12.5, Length 2.7 | 1200×2700 |

| Thickness 12.5, length 3 meters | 1200×3000 |

If you are looking for suitable material for a bathroom, toilet room or pool, you can consider the production of moisture-resistant GVL for the floor 1200 × 600x20mm “Knauf” Superfloor. You can also use the sheets presented in the table.

| Kinds | Dimensions |

| Moisture resistant, length 2 meters, thickness 12.5 mm | 1200×2000 |

| Thickness 12.5 mm, 2.5 meters - length. | 1200×2500 |

| Thickness 12.5, length - 3 meters. | 1200×3000 |

The table shows the prices for GVL of this manufacturer, depending on the size

GKL Knauf: special features

Offers manufacturer “Knauf” and acoustic GKL. This material has the following properties:

- reduces background noise

- allows you to improve perception,

- reduces echo.

Acoustic drywall allows you to create a comfortable environment in the room. Therefore, finishing with such material is required in cinemas, in classrooms, in recording studios and in offices for negotiations. Such material is used in apartments.

No less popular are the types of moisture-resistant GKL “Knauf”. It is used in the kitchen, in the bathroom and in places where high humidity is assumed.

Features of the installation of partitions with the help of Knauf products. In such ways, the installation of GKL and GVL sheets is carried out.

Watch this video on YouTube

Watch this playlist on YouTube

Previous Building materialsBrick tiles for interior decoration: price, choice of materials and laying technology

Next Building Materials LDSP: what is it and how to choose what is really profitable

Installation error of gypsum fiber sheets

In this article we talked about what is GVL

But it is equally important to know about mistakes that are often made by unscrupulous builders and people who do not know all the nuances of this matter. So that there are no problems during the work, and no alteration is required, the following rules must be observed

- Do not remove the chamfer before processing putty.

- To fix the gypsum fiber sheet to the frame, special screws are used.

- Between the plates during installation it is necessary to leave gaps. They need to be coated with special glue or gypsum putty.

- Do not ignore the preparatory work before finishing, namely: cleaning from dirt, leveling the surface, removing flaws and priming.

Following these simple guidelines will help you get the job done.

Scopes of GKL and GVL

Despite the fact that GVL has higher strength characteristics. OH cannot completely replace drywall. Simple material is used to align and create walls and partitions. The simplest partition includes a lattice frame of vertical bars.

Mounting sheets on the floor

Use for partitions and walls

GKL wall sheathing is often used, since this material is lightweight and does not create significant loads on the wall surface. Drywall is suitable for the installation of interior partitions and cladding frame buildings.

GVL for walls has high strength, which allows them to be used for covering industrial premises. Reliable sheets for installation in gyms are also relevant. With their help it is impossible to process complex surfaces, but they have a long service life.

Installation method for partitions

The arrangement of partitions from GCR is due to the optimal weight of such material. You can create lightweight zoning screens that can be easily dismantled if necessary. Such material can be used for wall decoration in residential premises: for children, bedrooms, living rooms and corridors. When performing repairs with a high level of humidity: kitchen, bathroom or veranda is recommended GVL.

Partitions with insulation

For the walls of the boiler room, switchboard or for other structures with increasing temperatures, it is better to use fireproof GKLO. This material is also suitable for decorative cladding of fireplaces and stoves. For facing the smoke channel in an unheated attic, you can use GKLVO.

Features and secrets of installing GCR on the wall can be seen in the following video:

Watch this playlist on YouTube

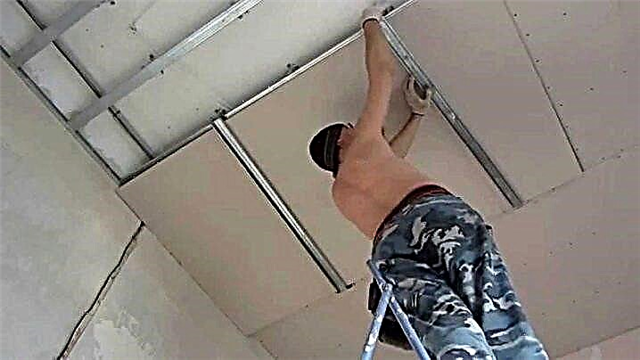

Ceiling application

The technology of installing GCR on the ceiling differs little from the installation of GVL sheets. But there are some features. GVL plates are heavy, so it is difficult to mount them to the ceiling alone. Self-tapping screws are used as fasteners.

Mounting the ceiling from GVL, it is required to cut the material. It uses a hand saw or jigsaw. All joints of the plates must be treated with gypsum putty.

When installing a suspended ceiling from GKL, you can get such advantages:

- the ability to create complex configurations,

- the formation of beautiful arches,

- application of any facing materials.

When installing a false ceiling in the bathroom, you need to choose a material with water-repellent characteristics.

Use in the interior

The use of gypsum fiber on the floor is especially relevant. At the same time, panels are used to withstand high humidity. Since the material has a minimum expansion coefficient, the joints will remain airtight. Interior decoration with gypsum boards allows to reduce the time for finishing work. GVL sheets can be mounted on wood or metal frames. This results in a perfectly flat surface, which is suitable for painting, wallpapering and for tiling.

With the help of drywall, a convenient TV shelf and functional niches are made

Often a device is used from the GKL of slopes of windows and doors. Installation is carried out before finishing is done. Drywall can be glued to the plaster. On door and window openings, the material must be glued over the entire surface, and not fragments. Remarkable and beautiful are the designs of arched openings from the GCR.

Using practical material, you can create interesting elements for the decoration of the ceiling

Scope of application

The scope of GVL is very wide and becomes wider. Over the past two decades, the volume of "dry construction" has sharply increased in our country, that is, without the use of mixtures, so the demand for gypsum fiber is growing steadily. So, GVL materials use:

- in construction and repair work of residential and public buildings,

- for wall decoration in industrial enterprises, as well as in trading floors and hangars,

- when sheathing any frame structures and building walls,

- for installing partitions indoors,

- for finishing work, when the walls need to be leveled,

- when installing flooring,

- as decoration of wooden and other walls in country houses,

- in sanitary facilities (in the bathroom, shower or toilet) for subsequent tiling,

- when facing technical rooms - pantries, attics, etc.,

- when decorating basements with standard and high humidity,

- in the decoration of the balcony and loggia - as an independent or draft finish,

- for decoration of premises with special fire safety requirements, for example, elevator shafts and evacuation corridors,

- due to environmental friendliness, it can be used in the decoration of schools and kindergartens (the natural background of irradiation is three times less than that of a widely used brick),

- for installation of floor coverings in sports and dance halls,

- when installing underfloor heating, since GVL-sheets have good heat capacity,

- in rooms where you need to place a hanging cabinet, shelves or heavy doors on the walls - gypsum fiber easily withstands even very serious loads,

- when creating cabinets and boxes for concealing plumbing and other communications,

- gypsum fiber impregnated with antifungal agents is used in construction and repair work in medical institutions and pools.

In general, we can confidently say that gypsum fiber materials allow you to perform high-quality construction or finishing work in almost any room, while the owner of the room can count on their durability and strength.

Features and Specifications

Thanks to various additives and high-quality gypsum, a mixture is obtained, which is converted into a gypsum fiber sheet using a press under pressure. The material is very durable, and structures made of it have a high bearing capacity. GVL from drywall is distinguished by the composition. Despite the fact that GVL is an analogue of drywall, it is much better and its operational characteristics exceed the opponent several times. Finishing with the help of such plates becomes more durable and reliable. Due to such advantages, gypsum sheets can be used when it is necessary to provide rigidity and strength of the partition. The uniformity of the material indicates its wear resistance and excellent resistance to mechanical damage.

Do-it-yourself GVLO sheet connection

GVL can be used as a substrate for flooring. Thus, it is possible to carry out installation without a lot of dirt and level the floor. Plates can be cut to the required dimensions, while leaving a minimum of waste, but if you select them correctly, you can speed up the installation and reduce costs. Although this material is mainly and better than drywall, it still has some disadvantages:

- Being a material with increased rigidity, it is difficult to obtain curved shapes from it. Plates bend poorly and therefore, for curly structures, it is necessary to use gypsum board

- The price of GVL is an order of magnitude higher, so for some such expenses would be undesirable. However, for the sake of improved features that extend the life of the material for a long time, you can spend a little

Convenience of mounting a GVL sheet, as well as finishing with its help, is quite simple. In addition, the plates have standard sizes, regardless of the manufacturer who makes the material.

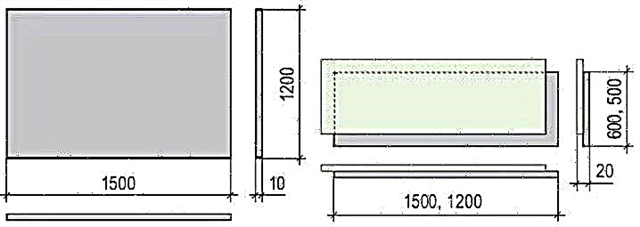

| Dimensions | Dimensions in millimeters |

| Length | 1500, 2000, 2500, 2700, 3000 |

| Width | 500, 1000, 1200 |

| Thickness | 10, 12.5, 15, 18, 20 |

When installation work is carried out in a private house, then the GVL sheets of 1500 * 1200 mm are used, the thickness of which is 10 and 12.5 mm. Such dimensions of the material allow you to work independently and not only align the walls with them, but also create partitions and even load-bearing walls. Installation of larger sheets, the thickness of which is 18 and 20 mm, and the length and width - from 2500 * 1200 mm, are carried out by qualified specialists. With the help of such plates, walls and partitions of large rooms and industrial structures are finished.

In addition to ordinary sheets of GVL, there are moisture-resistant, which is called GVLV. In the table below you can see the important characteristics of these plates.

| Feature Name | Value | unit of measurement |

| Humidity | Less than 1.0 | % |

| Density | No more than 1200 | Kg / m3 |

| Hardness | More than 22 | MPa |

| Bending strength | More than 5.5 | MPa |

| Thermal conductivity | 0,22-0,35 | W / m * s |

Installation of GVL sheets

In which cases is it possible to use GVL:

- Installation of gypsum fiber occurs during repair and construction works in apartments and houses where normal or low humidity

- It is possible to use GVL even in basements or attics, provided good ventilation

- If there is a desire to use GVL for walls in the kitchen or bathroom, where the humidity is high, then use moisture-resistant materials called GVLV

- In addition to the construction of partitions and wall cladding in the house, it is possible to clad even unheated buildings. Such can be garages, sheds and other utility buildings. The material is frost resistant

- The use of GVL provides fire protection for buildings built with wood.

In addition, the installation process does not require the use of adhesive solutions

Wireframe method

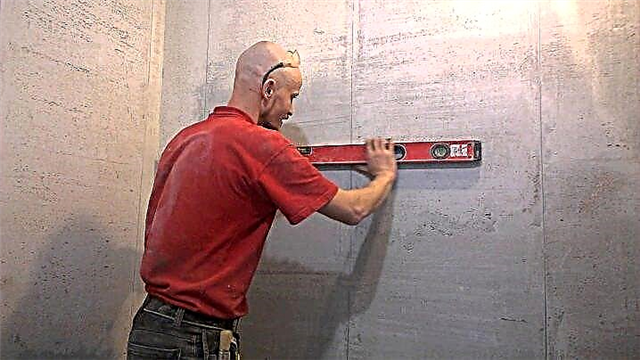

For this method, a metal frame is first mounted from strong galvanized profiles capable of withstanding heavy weight. In this case, you can use glass wool or other material for insulation and sound insulation. GVL is attached to the profile with special double-thread self-tapping screws. Stages of work:

- Surface preparation.

- Marking a wall using a level.

- Installation of profiles.

- Fastening sheets.

The photo shows that it is necessary to start the installation of GVL from the corner of the room, from bottom to top. After installation, all joints are coated with putty.

The GVL partition will turn out to be strong and sound. Its manufacturing technology is the same as for the GKL partition.

The main characteristics of moisture resistant gypsum fiber sheet (GVVV)

The very concept of "drywall" is quite broad, since it includes several types of this material. They differ significantly in operating conditions, and, accordingly, in their composition. In addition, there is such a thing as a “fibrous superlist”. Such material has several advantages compared to hl and according to the classification of Knauf is divided into:

- superlist (gvl),

- moisture resistant superlist (gvlv),

- superlist small format.

Each of the above options is characterized by increased mechanical strength, excellent sound insulation, fire resistance and has a special fibrous structure. The latter property allows you to accurately cut drywall and process the edges without much effort.

Technical characteristics of gvl (gvlv)

Gypsum plasterboard has special properties that allow you to use it not only for wall sheathing, ceiling, but also for the floor! Thanks to a high-quality mixture of fiber and gypsum, as well as special impregnation against chalking, the superlist can be used in buildings and premises of any purpose. The only fundamental difference in the use of GVL and moisture-resistant GVL is the ability to install the latter in places with high humidity. All the basic parameters of the sheets are shown in table 1.

Table 1. Characteristics of superlist gvl (gvlv)

Moisture-resistant material differs from the standard gvl in that its surface on both sides is treated with a special water repellent. This allows you to use it in rooms with any degree of humidity.

If we talk about the properties of materials, then they are very similar. The dimensions and weight of the moisture-resistant gvl are the same as that of the standard superlist. The following characteristics are also identical: humidity, Brinell hardness, ultimate bending strength, and thermal conductivity of gvl and gvlv. At the same time, the range of application of moisture-resistant drywall is wider than the standard one, since even in the bathroom it will “stand idle” the entire assigned service life.

Advantages and application of moisture resistant super sheet

Fibrous hl has all the advantages of conventional drywall:

- environmental friendliness

- high heat and sound insulation

- incombustibility

- mechanical strength and abrasion resistance,

- ease of installation.

He has only two drawbacks: price and substantial weight of the gvlv sheet (gvlv). The first problem can be solved by minimizing waste, and the second by using a good helper in the installation process.

Moisture-resistant drywall can be used in almost any type of building. Key use cases:

- in places with high fire hazard as wall and ceiling cladding,

- for cladding of attics, balconies and basements (if equipped with ventilation),

- for the construction of partitions in apartments with high humidity (for example, in bathrooms),

- for unheated rooms,

- for prefabricated flooring.

In the bathroom, it is recommended to additionally process the wall surface from the wall from Knauf with special moisture-resistant decorative coatings (paint) or overlay with ceramic tiles.

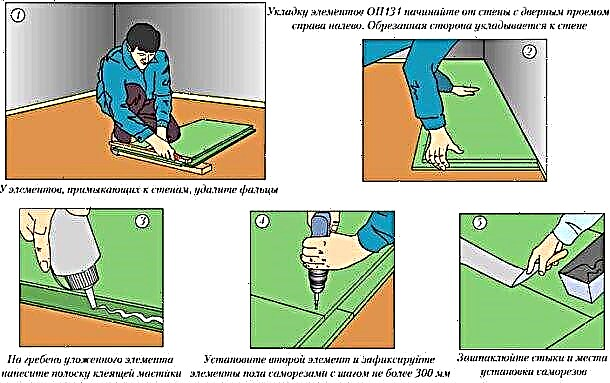

Installation of gvlv on the floor

Plates can be laid on almost any foundation: reinforced concrete or wood. For these purposes, the best option would be to use a 12 mm thick gvl sheet. The order of work will be as follows:

- Fastening a special edge tape.

- Filling with expanded clay or installation of insulation.

- Laying a gvl (gvlv) sheet of a standard size on the floor.

- Surface treatment of the first layer with glue or mastic.

- Installation of the second layer.

- Screed layers with screws.

- Primer.

- Installation of the coating (most often linoleum).

If it is necessary to mount the floors of the bathroom, then it is necessary to process the joints with a waterproofing tape. This will help prevent moisture from entering and prevent the structure from breaking prematurely.

Of course, GVLV is the “new word” in the development of construction business. It is especially convenient to use this material in the repair process with your own hands, since it is very easy to process. Moreover, on the market there are GVL sheets of various thickness and size, which significantly optimizes the work on the marking and installation.

The only important point is that you should not purchase materials from dubious manufacturers whose reputation on the market is not confirmed by real documents. Indeed, the compliance with GOST sheets of gvl and gvlv is the main guarantee of quality and safety of the whole structure. Nobody wants to remake most of it after a couple of tapes after repair. On how to avoid the most common mistakes, I would like to hear the opinion of experienced masters of "drywall".

GVL sheet size: how to work with material correctly

Each repair or construction is complete without the need to cut sheets. In order to accurately cut the plate, you can use an ordinary knife. In this case, in order to give the material the required size, the following actions should be performed:

Lay the panel on a comfortable surface

It is important to ensure that the sheet does not sag much.

Use a level or level rail to mark out.

Draw along the line drawn with a knife several times (at least 6-8) so that a deep cut remains.

Make a break. At the same time, most experienced builders argue that breaking should not be done down, but up.

GVL has established itself as a material that is easy to work with.

This method is considered the most elementary and long. If you want to speed up the process and have some skills in the field of construction, it is better to use a jigsaw, but you need to consider that in this case the work will be accompanied by the formation of dust.

Before mounting the sheets on the floor, you should prepare the base well:

- eliminate the old coating,

- close up cracks and other irregularities,

- remove all the trash

- waterproofing (if necessary).

The progress of laying sheets on the floor will look like this:

- First of all, a damper tape is glued to the surface, and then the panels themselves are already laid.

- Fastening can be done in two ways - using glue or self-tapping screws for HF.

- During installation, regardless of the size of the sheets, it is necessary to observe the recommended distance between fasteners, which is at least 20 cm.

- In order for the joints to be not so noticeable, they should be repaired with glue or putty.

After finishing work, you can immediately start laying the selected finish.

It is necessary to cut the GVL sheet after marking

Standard dimensions of paintings

GVL - sheet material. GOSTs provide for the sizes of paintings in centimeters:

- width – 50, 100, 120,

- length – 150, 200, 270, 300,

- thickness - 1, 1.25, 1.5, 1.8, 2, with increasing thickness, the strength of such a plate becomes more.

The standard sheet for household work is considered to be a canvas size of 150 x 120 x 1 cm.

In addition to standard sheets, many manufacturers produce highly specialized products. For example, Knauf produces special sheets for dry floor screed “KNAUF-super floor”, their size is 120 × 120 cm with a thickness of 2 cm. They are plates obtained by gluing two sheets of gypsum fiberboard with offset, due to which on both sides of each sheet a folding of 5 cm wide is formed.

With increasing thickness, the flexural strength decreases. This must be kept in mind during transportation and installation. Arched structures are created from such sheets, since they are very durable when bent.

Manufacturers on the back of the sheet mark on all three parameters (length, width, thickness). In the manufacturing process, cellulose fibers are added to the gypsum under pressure, and the mixture is pressed. The result is a dense reinforced canvas. If such a cloth is impregnated with special hydrophobic substances, a moisture-resistant sheet is obtained - GVLV. Since the surface of such sheets is not glued with paper, the resistance to fire also increases, compared with GCR.

The standard thickness of the gypsum sheet is generally 10 or 12 mm. Frames can be 1200 x 3000 mm or 1200 x 600 x 12 mm.

Compared with drywall, gypsum sheets are much heavier. Therefore, their installation is mainly carried out using a metal or wooden frame. The glue method can also be used, but for sheets with small sizes.

Nevertheless, the material is quite light and will not create additional load on the walls. therefore It is perfect for arranging partitions.

Custom offers

Custom sheets are usually smaller than standard sheets. As a result, they are much easier and easier to work with. Such sheets are used most often in individual construction.

Moisture resistant gypsum fiber a sheet with a canvas size of 150 cm by 100 cm by 1 cm is perfect for wall sheathing in a toilet, bathroom or small pantry. It can be mounted using an adhesive mixture.

Before installation, in this case, preliminary treatment of the wall surface with special hydrophobic compounds is necessary.

Sheets thicker than specified in the standards are usually used as a substrate for flooring. This makes it possible to level the floor without excess dirt. Atypical materials with a length of 360 or 600 cm are sometimes found on sale.

GVL sheets with dimensions of 150 x 120 cm, with a thickness of 1 and 1.25 cm, can be mounted independently. These sizes are suitable for the arrangement of walls, floors in private homes.

Larger sheets must be installed by qualified builders. Basically, these plates are finished with industrial enterprises.

In addition, the sheets are with a straight edge without chamfers, then the marking is applied - "K" and with a falsetto edge - "FC". Additionally, markings may be applied indicating the type of surface. "NS" - unpolished surface or "Ш" - polished.

When is use possible?

The material is used during construction work in rooms with normal and low humidity. You can use it even in the repair of attics, but only if there is sufficient air circulation. In the kitchen, in bathrooms and other rooms with high humidity, a moisture-resistant building material is used - GVLV.

The material is frost-resistant, this makes it possible to finish unheated rooms, for example, garages, sheds and other outbuildings. For wooden buildings, the use of GVL provides fire protection.

Due to its ease of use, you can easily erect a partition with your own hands or lay a footboard. This will significantly reduce the cost of repairs.

Like any building material, this one also has its advantages and disadvantages.

Positive characteristics:

- Since gypsum fiber sheet contains only gypsum and paper, it is an environmentally friendly material. When working with it, toxic substances are not released, there is no risk of respiratory tract diseases when sawing sheets. It does not contain synthetic resins and polymer inclusions; it can be safely used for interior decoration of residential premises.

- Resistant to temperature changes, therefore, can be used in unheated rooms.

- It has high noise insulation characteristics. It can contain noise 30–45 dB.

- HVL tolerates moisture well. Therefore, it is used in the decoration of kitchens and bathrooms.

- High fire resistance makes it possible to sheathe wooden floors, beams, walls.

- It has low thermal conductivity and is used for wall insulation.

- The high viscosity of the material allows you to hammer nails into it and screw in screws, while they will be securely fixed inside the sheet. This factor also affects the fact that the HLV is practically not cracked or colored. It is easy to cut to the right size with the same tools as drywall and plywood sheets.

- Lightweight, so you can use inexpensive profiles and frames during installation.

- The material is easy to process, minimum waste during installation.

- Due to the use of cellulose fiber, the sheet is more flexible than GCR. Its bending strength ranges from 5 to 6 MPa, and this is much higher than that of drywall. Therefore, it is easier to make complex decorative structures from GVL - arches, curved surfaces.

- Gypsum-fiber sheet withstands up to 20 freezing cycles without loss of characteristics, which allows it to be used for finishing periodically heated or unheated rooms.

Despite the huge number of advantages, the use of GVL has some disadvantages:

- heavy weight, one plate - about 18 kg,

- the price of GVL is higher than that of drywall,

- absorbs moisture well, this limits the use of the material or requires treatment with special water-repellent substances.

There is a large selection of product range on the market. Usually, the brand that first produced this product is considered the best manufacturer. Knauf is currently considered the best in all of Europe., although the most expensive. There are goods of domestic manufacturers on the market, but according to technical specifications, the material may be slightly worse.

When buying any building materials, it is better to make sure that there is a certificate for the goods and compliance with GOST.Make sure that there is a marking, it should indicate the size, type of edge, GOST.

For walls

Gypsum fiber sheets are used for walls in order to level the surface, for sound insulation and thermal insulation.

There are two ways to mount this material: frameless and using a frame. The frameless method is used if the unevenness of the walls is not too large. Apply special gypsum glue and press it against the wall. With this method, it is better to take sheets of small parameters.

If the irregularities of the walls are large, up to 3-4 cm, the sheets are glued with a special glue, applied around the perimeter and in the center, every 30 cm. If it is supposed to hang any shelves and cabinets on the wall, then glue the entire surface of the sheet with glue. Before installation, the material is brought into the room in 2-3 daysso that it adapts to temperature and humidity.

With the frame method, the GVL is attached using self-tapping screws with a double-row thread to the frame of durable galvanized profiles. Inside, you can put material for insulation and sound insulation. Profiles must be selected to support heavy weight. Installation is carried out from the bottom up, starting from the corner of the room.

After the installation is completed, sockets are cut and all the joints are sealed with putty.

For the floor

Mark the floor level. Lay vapor barrier. The use of GVL makes it possible to use the so-called warm floors. Expanded clay is poured onto the prepared surface and leveled. Sheets are coated with each other with glue and fastened with screws. Joints putty.

On this floor you can lay a laminate, tile.

If it is thin linoleum, then it is recommended to fill in the gypsum-fiber coatings with a layer of leveling mixture.

Such a wonderful material as gypsum fiber sheet is widely used in construction and repair work. This is a reliable building material for decoration. It justifies its high cost, which is higher than conventional drywall sheets, with a number of characteristic advantages.

See the next video for more on GVL.

The difference from drywall

GVL has many advantages over drywall:

- Much more durable. It does not deform under the weight of a person standing in heels, unlike GKL. Drywall can be broken by the hand, with a gypsum-fiber sheet this will not work.

- It does not crumble when cut, like drywall.

- Moisture-resistant GVL is much better resistant to moisture than GKL with similar properties.

- The noise and heat insulation properties of the gypsum board are higher than that of drywall, even without the use of additional materials.

- GVL painlessly tolerates 15 cycles of freezing, GCR can begin to crack after 4 cycles.

- The fire resistance of gypsum fiber is also much higher than that of drywall.

GVL plate has a more complex production technology than GKL. Therefore, its price is much higher. But the high cost is justified by excellent performance.

Frameless way

GVL is attached to the walls with special glue. Fastener Methods:

- With small flaws in the surface, gypsum glue is applied to the sheets and pressed against the wall.

- With large irregularities, special glue is applied to the sheets around the perimeter and in the center with dots every 30 cm. If shelves and cabinets are then hung on the GVL, then the entire surface is lubricated with glue to withstand the heavy weight of the hinged structures.

- If the wall irregularities are more than 4 cm, then narrow strips of GVL are glued to it at a distance of 50–70 from each other, and a whole sheet is glued to them.

Before gluing the GVL sheet, the material is kept in the room for 2-3 days, so that it adapts to humidity and temperature in the room.

You can see the detailed gluing technology in the photo.

The size of GVL is chosen based on the size of the room. Holes for outlets and wiring are cut out in the plates.

Floor application

After installing the GVL on the walls, you can begin to finish the floor.

- The floor level is marked.

- The vapor barrier is laid.

- A foam tape is glued along the walls.

- Expanded clay backfill is placed on the prepared base, leveled.

- A rough floor is assembled from gypsum-fiber elements, seams are oiled with glue, the elements are fastened with self-tapping screws through the folds.

- The joints are putty.

- After that, you can lay decoration material on tiles - tile or linoleum.

In the case of using a thin elastic coating, the manufacturer recommends pouring a leveling mixture with a layer of 2 mm or more over the gypsum-fiber coating.

It is impossible to make a complex curved design structure out of gypsum fiber sheet. But you can be sure that it will not break during installation and during operation.

Now you know what GVL is and how to mount it. The reviews of the masters say that this is a reliable material for wall decoration in apartments. GOST assumes the absence of toxic substances harmful to humans, so you can not worry about your health. The only significant drawback is the high weight.

Plasterboard partition

In addition to all the advantages in the characteristics and dimensions of GVL, with their help you can not only finish the walls, but also build partitions with your own hands. Thanks to the independent implementation of installation work, you can significantly reduce the cost of repair and construction works. The construction of the frame partition requires the construction of structures from steel profiles, which are further sheathed with GVL sheets in one or more layers. In order to achieve good sound insulation performance, mineral wool is laid between the gypsum boards.

Unlike difficult-to-install partitions, the frame method is quick and easy, in addition, it has good sound insulation performance. If the installation of the partition occurs after the construction of the box, it is better to use moisture-resistant GVL, especially if the room has not yet completely dried out. In contrast to the brickwork partition, various communications can be laid in the void between the GVL sheets. If pipes pass through them, then do not forget about the sound insulation layer that will cover the pipes. Do not forget about the opportunity to choose the necessary dimensions, thanks to which the installation of plates will become more convenient. Standard sheet sizes can be seen in table 1.

Prefabricated floor

Prefabricated floor

The structure of the walls sheathed GVL plates:

- To begin with, a frame is being erected. For this, galvanized metal profiles are used. The frame itself consists of rack and guide profiles

- After that, a soundproof layer is laid. A great option would be to use mineral wool or expanded polystyrene

- Then the frame is sheathed using self-tapping screws and GVL sheets

- We fill joints and joints - use quick-hardening putty for joints along with reinforcing tape

- We level the surface of the wall with putty. A thin layer is applied to the walls and allows you to create an even plane. You can use gypsum putty, and apply it with a spatula

- If in the future the walls will be painted, then we also use the finishing putty, which after drying is sanded with a grater or sandpaper

- To complete the process of wall decoration, you can use wallpaper, decorative panels or decorative plaster. Finishing with putty in this case is not necessary

GVL characteristics

Plasterboard slabs are made by combining gypsum and cellulose fibers from processed waste paper. The shape of the sheet is obtained by applying a press. Under high pressure, the components are compressed and turned into a sheet of gypsum fiber. Although gypsum board is some analogue of gypsum fiber, gypsum board sheets are much more durable and reliable and overtake gypsum board in many ways. These plates are used when it is necessary to carry out work on the construction of strong partitions.

Plasterboard can be divided into two main types: standard (GVLV) and moisture resistant (GVLV). It is also possible to distinguish plates with an edge in the form of a longitudinal line (designated as PC) and an edge with a fold (marked as FC). Sheets, for which there is no edge, are marked under the letter K. Sheets with a straight edge (PC) are used when sheathing of frame structures is required, that is, for walls and ceilings. It is worth considering that for the joints of such plates it is necessary to apply reinforcement. Sheets with a seam edge (FC) are two glued sheets that are offset along the axis relative to each other by about 30-50 millimeters.

The main advantages of GVL

- Such material is environmentally friendly, because it contains only cellulose and gypsum. For this reason, gypsum fiber does not emit any harmful substances and is absolutely harmless to humans.

- GVL sheets are very resistant to temperature changes, so they can be used even in a cold room.

- Such material is an excellent noise isolator. Often with the use of GVL, special screens are made to reflect extraneous noise.

- Gypsum fiber tolerates moisture very well, so it can be used even when decorating a bathroom or kitchen.

- The material is very resistant to fire, which reduces the likelihood of a fire.

- Gypsum fiber can be adjusted to any size by cutting it. Such material does not crumble, and if necessary, you can safely drive in nails or screw in it.

- GVL is also a good insulation, as it has low thermal conductivity. Plasterboard is able to retain heat indoors for a long time.

Standard sizes

GOST provides for various sizes of GVL boards in length, width and thickness. In particular, the following size options are provided by thickness: 5, 10, 12.5, 18 and 20 mm. The width distinguish sizes of 500, 1000 and 1200 mm. GVL length is presented by such standards: 1500, 2000, 2500, 2700 and 3000 mm.

Slabs and custom sizes are sometimes produced., for example, 1200x600x12 or 1200x600x20 mm. If you need to purchase a significant amount of non-standard products, it sometimes turns out to be easier to order it directly from the manufacturer than to find it ready-made in the store

The only drawback of GVL is that it is a rather heavy material, especially in comparison with its gypsum board. For example, a plate measuring 10 by 1200 by 2500 mm weighs about 36-37 kg. Therefore, during the installation of GVL, fairly strong profiles are needed, not to mention truly strong male hands. The fastening of such plates on the walls requires a strong frame. Sometimes, wood bars are used instead.

Small-sized plates can be fixed to the walls without the help of a frame. Their installation can be carried out using special glue.

GVL cutting

Sometimes during construction it is necessary to cut off the GVL sheet. For cutting gypsum boards, you can even use an ordinary knife.

The procedure is as follows:

- It is necessary to attach a flat rail to the GVL sheet, on which it is worth making a marking.

- Draw a knife several times along the marking (5-6 times).

- Next, the rail is placed under the incision. After which the plate needs to be carefully broken.

For inexperienced builders, the best way out when cutting a GVL sheet is a jigsaw. Only this tool is able to provide an even and clear cut of the plate.

GVL laying on the floor

Before installing the GVL sheets on the floor, it is necessary to carefully prepare the base. The old coating must be removed, and all rubbish must be removed. Even contamination deserves special attention, which, ideally, should not be - they do not contribute to adhesion. Irregularities and defects must be eliminated with the cement mortar from which the screed is made. Then a waterproofing layer is laid on the floor. If necessary, resort to adding expanded clay, this is done for additional thermal insulation of the floor. After the above actions, you can proceed directly to laying gypsum fiber sheets.

This is done as follows:

- First, it is worth sticking the damper tape.

- Next, the sheets themselves are laid on the floor. Their fastening is carried out by using glue or self-tapping screws. It is important to remember that the screws should be screwed in, observing a certain distance between them (approximately 35-40 cm are recommended). A new row is laid with a joint offset of at least 20 cm.

- At the final stage, it is necessary to carefully process all the joints between the sheets. This can be done with glue residue, but it is better to use putty. Then, any coating can be laid on gypsum fiber sheets.

Wireframe method

For this method, it is first necessary to make an iron frame that can withstand a large load. Also, under the frame, you can put additional insulation or sound insulation, there you can also hide electrical wiring, as well as other communications. The GVL sheets themselves must be mounted on the frame using special double-thread self-tapping screws.

The main errors in the installation of GVL

There are some subtleties that you need to consider when working with gypsum fiber sheets.

To avoid the most popular mistakes, follow these tips:

- there is no need to chamfer before applying putty,

- for fastening sheets to the base, there are special screws with double-row thread, which must be used,

- in the joints of the sheets it is important to leave gaps that are equal to half the thickness of the plate,

- such gaps are filled with plaster putty or special glue,

- Before installing the GVL, it is important to prepare the walls, that is, to level them, remove irregularities, and make a primer.

Things to consider when choosing

When purchasing GVL sheets, you should pay extreme attention to the manufacturer. Knauf company sheets, which have long established themselves in the building materials market, have very good quality. Analogs of domestic manufacturers, although they will cost less, but their quality is noticeably inferior to German. When buying moisture resistant sheets, you need to carefully read the product labeling. Such moisture-resistant sheets in appearance may not differ from the standard ones, so it is important to read what is written on the package.

When choosing any building materials, the cost should be the last argument in favor of the choice of a product. Good moisture-resistant Knauf sheets, depending on size, can cost up to 600 rubles apiece, but it is better not to be greedy, because the avaricious pays twice.

Conclusion

GVL sheets are very high quality and easy to process material. Their weight is quite significant, which puts a big load on the walls of the room, however, the advantages are numerous. It is possible to carry out installation of GVL with your own hands. Also, the material is very resistant to temperature changes, and even to high frosts. Most sheets are able to withstand up to 8-15 freezing cycles and not lose their properties. Such material is indispensable in the decoration of various surfaces, is guaranteed to meet all expectations and will please you with a long service life.

All about the properties of GVL sheets, see below in the video.