Soundproofing of rooms is not always carried out to protect against noise from the outside. There are many places where, on the contrary, it is necessary to exclude the possibility of sound penetration from the inside or improve the acoustics: a music studio, a sports hall, a home theater and the like. In addition, many soundproofing solutions are very time-consuming to implement, but, unfortunately, are not effective enough.

In the modern market of sound insulation there is a material that stands out among others - soundproof foam. This material is one of the most effective means for fast soundproofing of any room.

Soundproof Foam

Soundproof Foam

What is the difference between soundproof foam and ordinary

Foam rubber was accidentally obtained as a by-product of the production of solid polyurethanes. At first, scientists were looking for a way to avoid the appearance of this substance, but then they found widespread use for it. Depending on the density, up to 90% of the foam is air, the rest is polyurethane. The term "foam" in relation to foamed polyurethane foam began to be used in the Soviet Union thanks to the name of the company Poronon, which was the main supplier of this material, and was later preserved.

Polyurethane foam turned out to be an elastic material that perfectly dampens any vibrations and restores shape after even prolonged compression. Foam rubber is used as packaging, stuffing for furniture, in everyday life it is used as a replacement for an expensive natural sponge. Also, foam rubber showed itself well as excellent sound insulation.

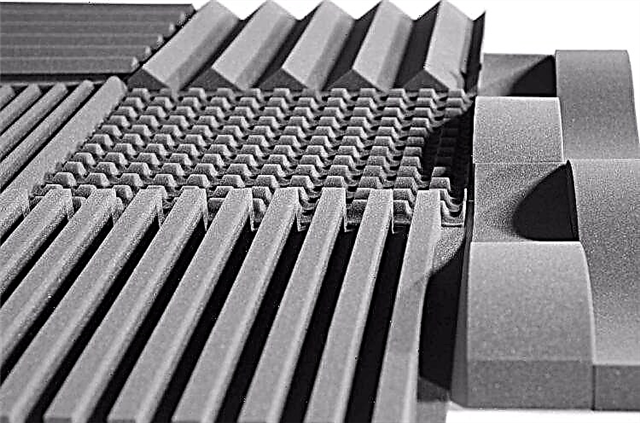

Sound insulation foam does not differ in composition from usual. The difference is only a special surface relief that dampens the sound waves incident on it and gives the room excellent acoustics. Due to this property, such foam is called acoustic.

Types of Acoustic Foam

Types of Acoustic Foam

The surface of soundproof foam rubber can be of the most various forms: waves, peaks, pyramids. If desired, you can order foam rubber of any relief. Manufacturers of acoustic foam pay great attention to how their products look, because installation is carried out directly on the walls and ceiling.

You can find soundproof foam not only of different shapes, but also in different colors: from classic black to brighter yellow, red, and purple.

However, soundproof foam rubber can be smooth, and can be used to fill voids in drywall partitions when arranging soundproofing.

Scope of acoustic foam

There are many places where the use of soundproof foam is appropriate or even necessary. Some of them:

- Recording studios. This is one of the first areas of application of acoustic foam. In such places, it is very important, firstly, to achieve the absence of noise from the outside, and secondly, to prevent the sound wave from reflecting off the surfaces and creating an echo. In addition, often the lyrics or melodies are trade secrets and should not even penetrate the walls of the studio in the form of echoes.

- Cinemas. We are talking about both public entertainment venues and small home cinemas.

- Rehearsal and assembly halls. Regardless of whether the group is engaged in a room, a dance ensemble or a choir - good acoustics will provide both excellent sound and silence in neighboring rooms.

- Sports halls and lecture halls - in any large-scale large-scale premises that are massively used, echoes very easily appear and spread.

- Production and office premises. Sound insulation in such places is often not provided, but, of course, the comfort and well-being of workers will improve if noise pollution is avoided. This is especially true in rooms of a large area with high ceilings, where even the sound from the falling of a handle or the movement of a chair is felt by considerable noise.

Recording studio with foam rubber on the walls

Recording studio with foam rubber on the wallsProperties of soundproof foam and its differences from other types of sound insulation

Soundproof foam has both obvious advantages and some disadvantages:

- Easy installation. Unlike most materials for noise insulation, foam is glued directly to a wall, ceiling or other surface.

- A variety of colors and reliefs allows you to combine the benefits and the original decorative solution.

- Excellent soundproof properties. Acoustic foam rubber is one of the most effective sound insulators.

- Lack of smell.

- High hygroscopicity. Due to its porous structure, foam rubber easily absorbs and retains water. Therefore, it is necessary to control the humidity level in the room so that the material does not get too wet, as this can contribute to the development of mold.

- Relatively high cost. Among noise insulation, foam rubber is more likely in the upper price segment, but given the savings on additional materials during installation, this is not a very influential factor.

- Vulnerability to mechanical stress. Foam must be handled very carefully, as this material is very soft and can easily break. For greater safety, it is sometimes fitted with a cloth.

- Combustibility This is the main disadvantage of soundproof foam. It is because of combustibility that this type of noise isolation does not receive significant distribution. This disadvantage is further compounded by the fact that the use of fire-fighting additives or impregnation for foam is impossible.

Room with acoustic foam

Room with acoustic foamBasic concepts

Conventionally, all materials today can be divided into sound-absorbing and sound-reflecting. Acoustic foam is classified as the first group of substances capable of qualitatively scattering sound waves within its structure. They make it from polyurethane foam or polyester, which during technological processes turn into a light porous material.

But this product should not be confused with ordinary foam rubber, as they have many distinctive properties.

Among the advantages of this product, several features can be distinguished:

- High-quality absorption of a wide range of sound waves. Sound reflection practically does not occur, which allows you to get pure vibrations within a certain isolated zone (living room, recording studios, and so on).

- Simplicity and versatility. The material can be mounted on almost any type of surface. But often acoustic foam is used for ceilings in order to minimize the external noise load. Installation of foam rubber does not require special skills and can be carried out even by an untrained specialist.

- Resistance to damage. The substance does not rot, and also does not collapse under the influence of various fungi and microclimatic factors. This allows you to use foam for a long time.

- Unique design. Panels can be complemented by various structures and color shades. Therefore, they are often not closed, as they fit well into the general style of the room.

But acoustic mats are not able to absorb low frequency sound. Therefore, you need to additionally use special "bass" traps. Such a complex is used only in recording studios, where the quality of acoustics plays an important role.

Caution, noise!

Noise is a collection of sound waves that are able to transfer their energy to physical bodies and reflect from them. A noise pollution - acoustic vibrations of various origin and spectrum, whose intensity and energy violate acoustic comfort. These fluctuations may reach from outside and form inside premises. Moreover internal ones are more dangerous than external ones. After all, the noise coming from the street is kept by the walls of the building and double-glazed windows. And there is almost no protection against internal noise in the room.

The only thing that can neutralize the internal noise load is sound insulation of rooms with acoustic foam. It eliminates two types of noise. The first is sound vibrations that propagate between free gas molecules, the second is vibration.

In other words, acoustic foam prevents the transfer of vibrational energy, which can cause vibrations in solids.

Usage environment

Soundproofing is not always needed. If the noise level is significant, then you can resort to the installation of protective acoustic systems.

Foam rubber of this type is used as a soundproofing material in various places:

- Industrial premises. It is especially common in places where there are many different machines that emit not only noise, but also vibration.

- Cases of mechanisms. Foam rubber is often inserted inside industrial air conditioners, as well as in diesel generators. But their service life is limited, as the material is quickly clogged with dust.

- Cinemas, television and so on. In such places, acoustic foam is almost always used for soundproofing ceilings and walls. Recording studios create “clean” rooms where you can hear and record your own voice without impurities.

- Residential buildings. Very often in panel-type buildings, the noise level is high. It spreads in most cases through the ceiling or walls, which are covered with such a substance.

Substances of this type are universal material. It should be understood that its characteristics do not depend on the location of the foam.

Types of Acoustic Ceilings

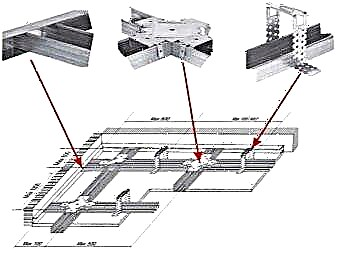

Sound modules are called the main component of acoustic ceilings, there are various ways to assemble such modules. By the principle of installation, the system is divided into stretch canvas, suspended ceiling structure, frame or frameless.

The frame type of acoustic embedded structures is equipped with a modular structure: going to the ceiling of separate solid soundproof slabs. But the frame itself is assembled from ordinary rails and profiles of different geometries. The finished profile creates suitable cells for the installation of soundproof slabs. Such the frame is usually fixed directly to the ceiling and walls, for fixing, tight gaskets are used, which dampen the sound vibration. There are no solid bonds in this system.

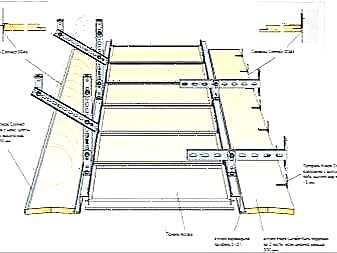

Frame ceilings, that is, their inner layer is formed by special sound-absorbing panels. It turns out something like a kind of sandwich, soundproofing material is placed inside, for example, foam rubber. Outside, the panel is finished with a beautiful decorative coating..

To date, many different methods have been developed that allow you to place the blocks inside the frame. Armstrong is referred to one of the known variations of frame ceiling structures - suspended systems, plates in this embodiment are installed in the upper cells. In such a ceiling design, acoustic recessed panels are usually not attached to the profiles. In the finished frame, various acoustic panels are installed that are suitable for the parameters for the cells.

Soundproof Frameless Panel System consists of facing materials, acoustic embedded sandwich panels. Such built-in acoustics differs from any other systems by the possible fastening of panels directly to the ceiling itself, so the need for assembly of the frame disappears. This type of fixation is made possible by the integrated mounting element in the modules themselves.

Frameless structures are insulated with soft cotton, creating airborne acoustic mats. Outside, the panels are lined with 12.5 mm gypsum fiber panels, so the material acquires a high level of hardness. The panels are mounted to the ceiling through a special vibration-isolating unit. The acoustic type of plates is selected according to soundproof parameters.

For example, 40 mm panels perfectly showed their unique characteristics during domestic use. But 70 mm modules are used to absorb the average noise. 120 mm panels are used in fairly noisy roomssuch as concert halls and movie theaters.

The stretch type of acoustic ceilings is made of PVC film. Such material has incredible soundproofing qualities. The film is processed in a special way, this allows you to enhance the effect, perforate the film with small holes or supplement it with an anti-noise layer.

A huge number of such holes prevents the penetration of sounds. Noise is muffled slightly in these holes. The film is pulled, using a special technology, the film is attached to wall frames.

Principle of operation

Acoustic foam has a porous structure. But its distinctive feature is the presence of open pores, which are interconnected by microscopic channels.

The principle of absorption of sounds by this substance can be described in several ways:

- A sound wave hits the upper layer of foam. Often it has an uneven surface. This causes the flow to beat off and penetrate into the structure.

- The sound, getting inside the pores, begins to change the direction of its movement and begins to fade. This is achieved due to various air resistance, which reduces the amplitude of the waves.

Please note that the quality of sound absorption depends on many physical characteristics of foam rubber. Some of them are designed to work with medium, and some with high frequencies. Specific characteristics can be clarified only with the manufacturer of this product.

Acoustic foam: we use for effective work in the office

It is known that in offices internal noise pollution forms and spreads — steps, knocking of drawers, doors, furniture, office equipment, making calls and talking on a cell phone — even if employees try to be as quiet as possible. All this reduces labor productivity and makes it difficult to focus on work.

However, if you equip the room with acoustic foam, you can minimize sound vibrations.

According to experts, it is enough to place acoustic foam panels in small office rooms only on the ceiling, which will reduce the noise pollution by half. And if you also cover the walls (in particular, two adjacent ones), the problem will be solved completely.

Thanks to the soundproofing of the room, people hear and understand each other better. This relieves the nervous system of stress, causing various disorders, including chronic fatigue syndrome.

Video on how acoustic foam rubber works:

Mounting technology

Many experts say that it is possible to improve sound insulation in an office or a living room by installing foam boards on the ceiling.

This process is relatively simple and is carried out in several consecutive steps:

- Formwork construction. Here, the same approach is used as for wall cladding with heat-insulating materials. Several wooden planks are nailed to the ceiling. The distance between them depends on the size of the panels themselves. It is desirable to align all the trims in one plane, which will simplify their further decoration.

- Ceiling cleaning. Theoretically, foam can be glued to any material. For this, special adhesive compositions are used. But if the base is heavily soiled, then it will not be possible to form a strong bond between the components. Therefore, it is advisable to thoroughly clean the ceiling before fixing the material.

- Foam fastening. The process is relatively simple and involves applying glue to the surface of the ceiling, followed by fixing the material. It is only important to distribute the composition evenly to ensure strong adhesion.

- Decorative finish. The process is completed by covering the ceiling with sheets of drywall. This material also absorbs sound waves well, so you can achieve unique and high-quality indicators of this design.

If such a "built-in" system does not suit you, you can glue foam mats directly to the ceiling without a frame. But this option will not always allow you to create a beautiful interior.

This is suitable for offices or cinemas where all the design attributes are tailored to the same style.

Acoustic foam is a unique product that can categorically change the level of sound insulation in the house. Before using this product, it is important to consult a specialist who will select the optimal type of panels that can solve specific tasks.

For information on how to equip a room for home recording, see the next video.

Installation

The sequence for mounting frame sound insulation is traced on examples of the layout of the suspended structure. Installation begins after fixing the nodes directly to the ceilings themselves on the ceiling. Such work should be done in conditions of 70% humidity, meanwhile the temperature should be from +15 to -30º.

First you need to check the completeness of the entire speaker system.

Usually this kit is going to:

- from acoustic plates, while the product size is 600x600 mm,

- carrier profile, the length of which is 3.7 cm,

- 1.2-centimeter longitudinal profile,

- cross 6-centimeter profile,

- 3-centimeter wall profile with tight elastic gaskets,

- adjustable suspensions,

- metal profiles, where the width of one shelf is 15 mm,

- profile of the T-shaped type and wall L-shaped type.

The assembly of the ceiling structure occurs according to a certain principle:

- Mark up to fix the wall battens. For such work, you will need to use a water level. It is necessary to draw a horizontal line under the wall profile at the smallest distance from each plate, while taking into account the equipment fixed on the ceiling.

- The bearing rail is marked in the range of 1.2 meters parallel to the wall.

- The markings of the longitudinal profile are applied perpendicular to the marks for the bearing rails, such a gap should be 0.6 meters.

- The cross-sectional marking is applied perpendicular to the longitudinal marks, while the distance between them should be 1.2 meters.

Marking is applied to place the suspensions, which will be located above the supporting profile at a distance of 1.2 meters, not more than 0.6 meters from the wall. It is rarely possible to complete 0.6 meters, so it is recommended to arrange chess markup. At the same time, the load on the installed suspensions should not be exceeded (3.5-6 kg / m²).

For more powerful panels, a reinforced type of suspension is used.

- Special marking will allow you to accurately calculate the number of suspensions, the necessary rails, mounting plates, it will be possible to determine the size of the modules. If necessary, cut the profile with a hacksaw.

- The wall type of profile is fixed by marking with screws at a distance of 0.5 meters.

- By marking, with the help of anchors, suspensions are fixed directly to the floor panels. When making mounting holes, special precision is not necessary. A small slope after eliminating a change in height.

- Next, a supporting profile is attached to the suspensions, they should be aligned in a single plane using an adjustable type of suspensions. Too long profiles are connected on the floor, and then attached to the installed suspension.

- Next, all remaining profiles are fixed to the already mounted rails.

- Acoustic plates are installed directly in the cells located in the assembled frame. The sloped slabs are raised above the raised ceiling, and released to the prepared place horizontally.

- When the panel gets stuck during installation, you cannot click on it, you can only push it from the corners. To the installed plates with lamps, electric wires are connected immediately.

- The last plate should be supported with your palm during installation.

In the next video you will find an experiment using acoustic foam.

Pledge of high-quality sound recording

The main field of application of embossed acoustic panels is the premises where rehearsals are conducted and phonograms of vocalists' songs are recorded. It goes about recording studioswhere acoustic foam can be placed not only on the ceiling and walls, but also on specialized sound-absorbing screens.

This is due to the fact that great attention is paid to the control of acoustic parameters in such rooms: they are tuned to different frequencies.

Fiberglass plate type

This material is made from elongated fiberglass yarn. This thread is laid in the same direction. The size of the fiberglass yarns allows for the production of a one-piece panel web of longitudinal direction. The fibers are bonded with a special polyester resin.

Fiberglass plates are moisture resistant, respectively, this material is used as sound insulation for rooms with a high level of humidity. The front, as well as the reverse side of the coated plates. Decorative cladding is made from a special polyvinyl chloride film, it is also made from aluminum laminate and perforated sheet metal.

Acoustic waterproof panels are finished with sheet material of glass felt or aluminum foil is used. The dimensions of the panels start from 60x60 cm and reach 1.2x1.2 mwhile the maximum thickness of the product reaches 100 mm.

For attaching acoustic fiberglass plates using a proprietary frame or some other suspended acoustic canvas with special cells of the desired size. You can fix the plates with adhesive or use screws.

Slabs made of stone wool

Such an insulating type of product is made from dolomite, limestone, basalt, the plate is processed using a specific technology. To achieve an increase in soundproofing qualities, perlite or clay is added to the composition of the material. The fibers bind with gypsum, starch or latex. The panels, which contain more latex, are characterized by high waterproof performance, such products can be mounted in rooms with high humidity.

The front surface of the plate is painted in various colors.. You can apply another method of decoration, for example, cover the plate with special foil paper.

To increase soundproofing characteristics, a highly effective sound-absorbing membrane is attached to the walls.

Tiled material is made from quality stone wool. The thickness of the product can reach 120 mm. The dimensions of such panels are 600x600 mm, this allows the use of products for other acoustic structures.

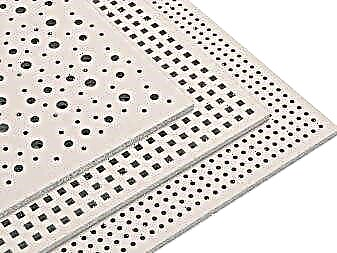

Gypsum plasterboard panels

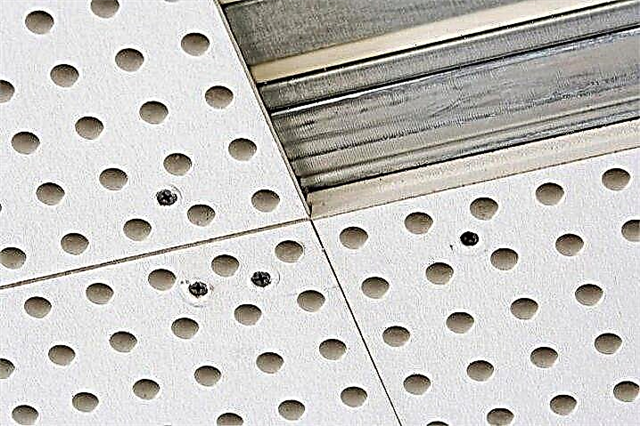

Often, perforated type of gypsum boards 595x595 mm with 8.5 mm thickness is used to install sound insulation. In this case, the front part can be decorated with various materials, the back side of the products is covered with a sound-absorbing layer made of non-woven material.

Sound insulation characteristics are attached to drywall by existing openings, which occupy up to 15% of the total quadrature.

Perforated drywall is easier to suppress the low-frequency type of waves. The generated echo is reduced, while the audibility in the room remains excellent. Sounds flow evenly.

Typically, perforated drywall is used in rooms with a moisture indicator of up to 95%. Plasterboard panels are installed in a high-quality system, or various frame ceiling structures with appropriate cells are used for this.