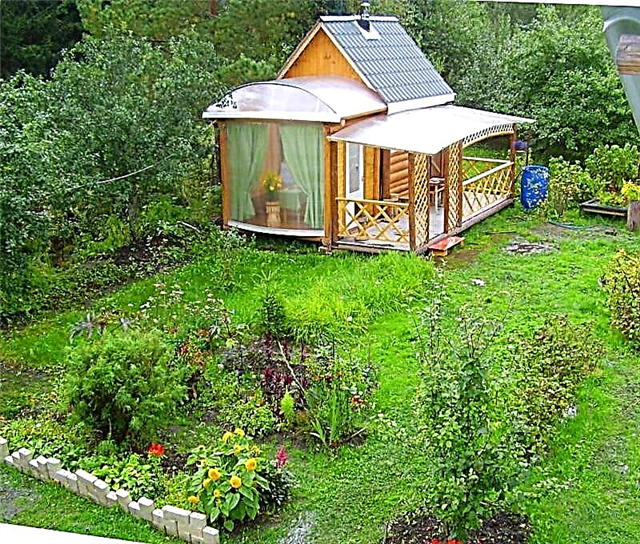

Your house or cottage, decorated in the style of a wooden house - an example of coziness and comfort. A few decades ago, this seemed like a pipe dream, because building a log house is so expensive and difficult. Now you don’t need to make so much effort, the modern type of block house block completely imitates the real log and allows you to complete the interior decoration of the house in a colorful style, regardless of what materials and how long the building was built.

But what about finishing work? Is it really necessary to hire a professional team of workers to transform your home, bathhouse or even a gazebo? It’s not so, it’s not at all difficult to complete a block house installation yourself, simple instructions and videos will help to do everything efficiently and quickly.

Material selection is the basis for a perfect interior finish

The choice of a block house for DIY installation in interior decoration differs from lamellas for outdoor use. Inside, the tree performs a more aesthetic function with additional insulation and sound insulation. Due to the special convex shape of the lamellas, such cladding takes up a lot of internal space and it is better to give preference to a smaller, more elegant size. To recreate any type of interior, a board with a width of 20-24 mm will be enough.

Like other types of lining, the block house is divided into 4 classes depending on the quality of the lamellas. The most budgetary classes, far from ideal in appearance and degree of processing, classes C and B are not suitable for interior decoration. This lamella contains knots, bark residues, chips and other defects. Performing a block house do-it-yourself installation, use high-quality classes A or Extra. Such a board not only looks great in the finished version, but is also easy to install, due to the matching size of each lamella, the installation turns into a pleasant pastime.

The class decision has been made, but what about the type of wood? The block house for internal and external works can be budget, made of pine or spruce, or made of elite wood. If there is a desire to preserve the natural pattern of the tree, preference is given to beautiful species: linden, larch, alder or oak.

To save money, budget spruce and pine are suitable. There are a lot of knots in them, you can turn this minus into a highlight or just paint the lining in your favorite color. The exception is the steam room in the bathhouse and other hot rooms, where conifers will emit tar.

If desired, and a sufficient amount of funds, you can perform a block house do-it-yourself installation of elite wood. It looks great, but it will also be expensive.

Preliminary preparation of the block house

Wood is a living material, it allows air to pass through, does not create a greenhouse effect and maintains a pleasant atmosphere. So that after mounting on the wall it does not deform, it should be protected from rotting and mold; special preliminary preparation is necessary.

The newly purchased lamellas are brought into the room where the decoration will be performed, they remove the film and leave the material for several days, to equalize the temperature and humidity. Also, at the preparation stage, wood is treated on all sides with protective antiseptics and heat-resistant impregnations.

Lathing, insulation and fixing materials for quick and easy installation

The classic way of attaching a block house involves a lathing device. It’s better to start work by marking the walls to make the installation as even as possible. The block house is traditionally mounted horizontally, so the lathing is performed vertically.

In the device of the crate for internal work, I use a bar measuring 40x40 mm and strips 20x50 mm. First, the entire wall is covered with a foil layer of vapor barrier material, and then the fixing of the crate begins. The beam is nailed with nails vertically, as the basis of the supporting structure, and the plank between it horizontally, as an additional reinforcement. The step between each bar is kept within 40 - 50 cm.

The next stage of work depends on the purpose of the room. If it is a bathhouse or sauna, additional insulation with mineral veil is necessarily performed. If the block house installation is done in the home in a warm residential building, the insulation can not be laid.

Clamps are best used as fasteners. They are easy to install, invisible under the finish and make it possible to expand and narrow the lamellas under the influence of seasonal temperature changes. If desired, you can fix the board with nails and even self-tapping screws.

Advantages and disadvantages of a block house

Like any other material, a block house has its pros and cons, based on which you can decide whether to use it as a decoration or not.

To the main merits can include:

Environmental friendliness. Since the block house is made of natural wood that has previously been dried, the main advantages of it can be attributed to environmental friendliness. The coniferous house block has high strength properties, allows you to maintain indoors good microclimate and of hardwood, it has good moisture resistance and hardness. Due to the relatively high content of natural resin in the materials, a natural waterproofing is created, which increases the life of the structure, and due to its resistance to decay, the product can be placed in a humid environment,

Environmental friendliness. Since the block house is made of natural wood that has previously been dried, the main advantages of it can be attributed to environmental friendliness. The coniferous house block has high strength properties, allows you to maintain indoors good microclimate and of hardwood, it has good moisture resistance and hardness. Due to the relatively high content of natural resin in the materials, a natural waterproofing is created, which increases the life of the structure, and due to its resistance to decay, the product can be placed in a humid environment,- Mechanical strength. The block house can withstand the effects of the external environment (sand, degrees), is resistant to UV rays and can serve for a long time without losing its strength and aesthetics,

- Aesthetics. Of course, aesthetic characteristics are completely dependent on the environment and the place where the construction is underway. But, nevertheless, this material has great look and is capable of emphasizing the beauty of the house with its wood trim. The block house can be used for both external and internal decoration, while it does not require additional finishing work.

- Easy assembly and light weight. Since the block house is a fairly lightweight material, home decoration can be done by independent efforts, without involving a team of specialists and the use of heavy equipment. Also, due to the light weight of the board, the loads on the foundation of the house are reduced.

In addition, the advantages of the block house can be attributed providing additional warming at home, resistance to corrosion and deformation, durability, a variety of colors of wood and so on. All this contributes to the creation of optimal conditions for living and being in the building of people.

disadvantages house block:

Low vapor permeability. When using a house block as a finishing material, the risk of condensation and moisture accumulation between the cladding and the wall of the house is quite high. For example, it can occur during the heating of a “cooled down” house. You can avoid this problem if you install a high-quality ventilation system in the house.

High flammability. Since wood is used to make the house block, this finishing material has high combustibility. But this problem can be dealt with if the boards are soaked in a refractory solution.

Block house is a universal material that is used both for the external cladding of the facade of the house, and for interior decoration. The smell of natural wood favorably affects the nervous system and mental state of a personcreates a cozy, homely atmosphere. The tree heats up quickly enough and keeps warm for a long time, therefore this material is used for facing baths, saunas, balconies and loggias. For exterior decoration use a wide block house imitating wooden logs. It can be arranged both on brick and on a wooden log house.

Block house is a universal material that is used both for the external cladding of the facade of the house, and for interior decoration. The smell of natural wood favorably affects the nervous system and mental state of a personcreates a cozy, homely atmosphere. The tree heats up quickly enough and keeps warm for a long time, therefore this material is used for facing baths, saunas, balconies and loggias. For exterior decoration use a wide block house imitating wooden logs. It can be arranged both on brick and on a wooden log house.

Features of selecting a house block for home decoration

In the modern construction market of varieties, there are a lot of house blocks, and you need to be able to choose the right quality material so that it does not fail and lasts a long time.

First, you should pay attention to the width of the board - for facing the facade, boards are used, the width of which should be not less than 150 millimeters. For interior decoration, boards with a width of 80 millimeters are best suited - such thin panels can increase the area of the room. Strengthen this effect will be able to block the house from light varieties of wood.

Next, you need to determine the type of tree from which the board is made. Siberian larch, which does not warp under the influence of moisture, is an environmentally friendly material, is well suited for external decoration beautiful natural color and interesting texture.

For interior decoration, oak and linden boards can be used - they will provide good waterproofing, and when heated, tar will not stand out, leaving sticky spots.

For interior decoration, oak and linden boards can be used - they will provide good waterproofing, and when heated, tar will not stand out, leaving sticky spots.

When buying a house block, the category of wood should be clarified, since high quality finishes can be achieved using only wood of the highest category. Boards should be packed, have one length and width. A good house block should not have rotten knots, through holes, cracks and cracks, tar spots and pockets.

Preparatory work, installation and fastening of the house block

Finishing work is best done one year after the construction of the house. If a block house is sheathed by a wooden house, then you need pierce the wallsto avoid unnecessary heat loss. Boards should be left indoors for a couple of days to avoid the formation of cracks, and then cover them with an antiseptic.

Work order:

- waterproofing with a moisture-proof film,

- fastening guides to the facade. At the same time, it is worth using the construction level to avoid possible distortions,

- laying of thermal insulation material between the guides. Mineral wool slabs or staple fiber are ideal as insulation - they are not combustible,

- waterproofing on top of the insulation,

- fixing holes on the front side of the house block. The panels are fastened with a punch,

- fixing boards to guides in the horizontal direction

- pouring glue on the screws and hiding them with special overlays.

The installation of the house block can be carried out from above and below, simultaneously throughout the building, in order to precisely align the boards in the corners. Joints can be covered with slats, attaching them with specialized glue.

Block House Care

To extend the life of the house block, as well as protect the skin from external influences, after the fastening of the panels, coat them with a primer and then wax-based varnish. After the varnish dries, it is necessary to sand the surface with sandpaper and again apply a couple of layers of varnish (or paint) of the desired color. It’s better not to save on materials, because the appearance of the home depends on them. It is worth updating the cover at least once every five years - this will help update the building’s facade and extend the life of the material itself.

Since under the influence of water, the block house is easily deformed and loses its original properties, it is possible to mount gutters on it, which will protect the walls of the house from rainwater.

Since under the influence of water, the block house is easily deformed and loses its original properties, it is possible to mount gutters on it, which will protect the walls of the house from rainwater.

Block house is becoming more and more common material for decorating walls of buildings every year. All these characteristics provide these panels with an increase in demand, and the ease of installation makes it popular among people who started repairs. The only difficulty may be the right choice of a house block among all species provided.

But, having completed all the installation of the block house, the appearance of the house and its interior will surely please everyone around, create a favorable and cozy atmosphere in the house, and thanks to its environmental friendliness, they will be able to protect and maintain the health of loved ones.

The direct process of installing a block house on a crate

Regardless of the size of the lamella and the type of room, a block house, DIY installation is not too difficult, but a painstaking task. The profile feature implies installation only horizontally, in the case of a vertical mount, the finish will look rude and illogical.

The tongue-and-groove system provides two attachment options: spike down or spike up. The choice of the esthetic function is not too reflected, but for wet rooms it is extremely important to place the lamellas with the thorn up, then moisture will not accumulate in the grooves and problems with mold and rotting will be avoided.

We begin the installation from below, the first row must be fixed with nails, each subsequent board is attached with a kleimer and the process continues along the entire necessary height.

If you don’t want to work with the clamps, you can fix the block house with small studs through the spike or through the lamella. In the latter case, the holes and caps will be visible in the finished finish.

Docking the corners of the block house

Installing the finish on a flat wall is not so difficult, but what about the corners? Their proper design plays an important role in the overall picture.

Two of the most faithful and aesthetically pleasing ways: washed down according to the pattern or at 45 degrees. As a result of the applied efforts, the corners will be made perfectly, without the need to supplement them with any plastic corners or other elements hiding unevenness.

Block House Interior Finish

After the completion of all installation works, the last stage remains - finishing. It all depends on personal taste and interior design. The most stringent rules apply to hot rooms (baths and saunas), varnish or paint is unacceptable here, in order to avoid the release of chemicals when heated. In an ordinary residential building, lamellas with a beautiful wooden pattern can be coated with transparent or slightly tinted varnish.

If you want to radically change the color and style, paints will come to the rescue for interior decoration of any color.

Features and specifications

The block house is a unique decorative material. It is available in the form of boards having a flat inner and convex outer sides. Also, the device device includes docking parts (spikes and grooves), which provide reliable fastening, avoiding the formation of gaps and crevices during installation. For the manufacture of a block house, various wood is used, but most often raw materials from deciduous and coniferous trees are chosen, which are characterized by excellent aesthetic qualities, hardness and strength.

Boards during the production process undergo high-quality processing, so they are suitable for installation in any conditions. The main feature of the material is that during operation it does not crack. This is due to the fact that in the manufacture of the house block it is equipped with special grooves that relieve stress from the tree.

The material is produced in various sizes, which makes it possible to apply it both for internal and external decoration. The lining of the premises, as a rule, is carried out using a wooden block house with a cross section of 46 * 180 mm, and metal or vinyl panels are chosen for the decoration of buildings from the outside.

The main characteristic of the boards is their class, which is determined by the quality of the wood and how it is processed.

Therefore, on sale you can find products of two options.

- Block house of the highest category.It is considered the highest quality, intended mainly for exterior cladding. Such boards are characterized by the absence of chips and holes.

- Simple panels. Such products have a lower price, so often on the surface of such boards you can find a slight “fringe” or “hairiness”.

It is also worth noting that the block house has different thicknesses of panels, starting from 20 mm and ending with 50 mm. At the same time, the minimum width of the boards is considered to be 70 mm, and the maximum - 190 mm. Before installing decorative wooden panels, they must be carefully processed: primed and covered with several layers of varnish or paint. After the painted wood dries, it is ground and covered with a protective layer, which must be updated every 5 years.

Since the block house is available in a wide range of colors and textures, it can be used for cladding any types of premises and buildings, regardless of style. Country houses look especially beautiful in this design. The decoration is a real decoration of landscape design. If you sheathe the material inside the walls inside the building, you get an unusual effect, thanks to which the interior is filled with comfort and domestic warmth.

Types: advantages and disadvantages

Since the block house is made from various raw materials, it is divided into several types. The most popular is a material made from natural wood. The main advantage of such boards is their environmental friendliness. The basis of the wooden block house can be spruce, pine or larch, so choosing it for the outer lining of the house, you can get an unusual decor with an imitation of a log house.

Depending on the quality of the massif, wooden panels are divided into three groups.

- Class "C". Boards have a well-planed surface, without knots and other large defects. However, for these products a slight presence of browning, chips and scratches is allowed.

- Class "B". Cloths are characterized by a low price, so traces of mechanical damage, light and dark knots may be present on their surface.

- Class "Extra". The boards are perfectly crafted and free from any flaws. They are expensive, because they are characterized by high quality, which is achieved by manual selection method.

Regardless of the class of production, the following advantages of a wooden block house can be distinguished:

- good heat and noise insulation,

- presentable appearance

- naturalness.

As for the negative properties, such boards are expensive, easily ignite and require treatment with antiseptics.

If you plan a budget option for decoration, then the right choice will be vinyl panels. They are sold at an affordable price, imitate natural wood. The main advantage of the products is that before installation they do not need to be additionally saturated with antiseptics and varnished. In addition, compared with wood, they have a longer life and do not require special care. Since the vinyl block house is lightweight, it does not exert pressure on the structure of the building.

The advantages of vinyl panels include:

- a huge selection of textures and colors,

- ease of installation

- durability,

- resistance to moisture and ultraviolet.

Such a material has few disadvantages: it is sensitive to temperature changes, requires special installation technology, and the surface of such boards looks duller than an array.

Steel block house is considered to be no less popular. It is a bent profile painted under a natural tree. Thanks to this material, you can not only decorate the facades, but also provide high-quality thermal insulation. The main advantage of the product is its high strength, but similar to vinyl panels, the material is suitable only for external decoration, since it looks unpresentable indoors.

The advantages of steel panels include:

- long service life

- affordable price,

- ease of installation,

- moisture resistance and fire safety.

However, despite the positive characteristics, steel elements also have disadvantages. They quickly heat up in the sun, and their installation requires the use of additional components.

Criterias of choice

The construction market impresses with a huge assortment of block house, but in order to complete a high-quality finish, you need to choose the right material.

The product should not only have a beautiful appearance, but also have operational characteristics that allow it to last a long time.

- A huge role in the choice of panels is played by their width. For cladding of facades, it is better to choose a board with a width of at least 159 mm, and for interior decoration - 80 mm. The use of wide panels is not recommended for wall cladding in rooms, as they visually reduce the area of the room.

- Particular attention must be paid to the type of wood from which the material is made. For outdoor work, larch is suitable, it is resistant to moisture, has an original texture and color. When decorating inside buildings, it is best to give preference to linden or oak. They provide excellent waterproofing and insulation of the room.

- When choosing a block house, you also need to clarify the class of its wood. The perfect skin can only be obtained from high-quality panels of the highest category. Therefore, all boards should be packed in a single film, have the same width and length. The purchase of material on the surface of which there are cracks, knots and tar spots is not allowed.

- It is recommended to buy boards with a length of at least 6 m, this will reduce the number of joints during installation.

- If the products do not have certificates, and the humidity of the boards exceeds 20%, then they cannot be used for decoration.

Preparation and accessories

Before starting installation work, a block house should be prepared. For this, a short period of time is allocated for the acclimatization of the material. This usually takes several days. At this time, insulation, waterproofing are laid outside the walls and the material is calculated in a cube.

Also, the installation of panels provides for the assembly of a vertical crate from battens or bars. The distance between the elements of the frame should be 70 cm. In order to provide the necessary waterproofing, a thin frame is additionally attached to the self-tapping screws on the insulated crate.

To install the boards you need to purchase certain accessories.

- Universal strips.

- Hinged profiles. Their fasteners are usually performed over window openings to protect the finish from moisture. If the facade consists of several levels, then profiles are used between transitions.

- Starting bar. It is necessary for mounting the bottom row of boards.

- Finish profile. It is placed along the edges of the wall to fix the last panels.

- Connecting levels and corners.

- Special fasteners (kleimer and screws).

Installation tools should consist of a standard set including tape measure, level, screwdriver, hammer and drill.

Technology and installation rules

When the crate is made, it will be possible to start mounting the block house panels. Laying the material is a simple process, so you can do the work yourself without the help of specialists.

To correctly perform the installation, it is enough to adhere to the installation rules. It is also important to ensure that the finish is firmly attached. Boards to the frame must be fixed with metal brackets or kleimers. If the lining is carried out with thick panels, it is recommended to use self-tapping screws coated with an anti-corrosion compound.

The installation of the panels begins with the fact that they are laid out in the room so that the spike of each part is on top and the groove is on the bottom. This simplifies the further workflow and reduces the risk of dust formation in the grooves. Between the ceiling, the floor surface and the cladding, it is important to provide for a small gap to ensure natural ventilation. You also need to leave gaps between the panels themselves when they are docked. This is done so that the skin does not undergo deformation when temperature changes and moisture gets on its surface.

It is worth considering that the exterior decoration of the facade requires the presence of additional materials such as insulation, antiseptics, primer and vapor barrier film. Before covering the house with a block house, you need to install a vapor barrier. The work is carried out using staples and a stapler, with the help of which the film is fixed to the frame, forming an overlap of 10-15 cm.

If the block house is mounted horizontally, then the bottom corner should be sheathed first. The panel is mounted on the profile and fixed along the entire length with a clamp, which, in turn, is attached to the crate with screws. Then the second panel is inserted into the milling cutter, its groove should “look” down.

Following the above technology, you should sheathe the entire wall. In some cases, the installation of the material is carried out not with clamps, but with self-tapping screws. In this case, it is important to precisely join the panels, screwing the screws at an angle of 45 degrees.

As for the design of the corners inside, they are decorated with a 5 × 5 cm beam or special skirting boards. At the same time, experts advise installing bars before sheathing. Thanks to this, the finish is more attractive.

Do not forget about the cladding of window and doorways. The most important thing is to protect them from the ingress of dust, precipitation and cold air. It is better to choose platbands with carved patterns or unusual ornaments. They can be curly, rounded or flat.

The block house also looks interesting in the interior of residential premises.

Such lining is practically no different from the outer lining, but is characterized by its nuances:

- usually use narrow panels for work,

- internal and external corners are formed at the end of the entire installation.

The use of a block house for decorating walls in rooms with high humidity is not recommended. If the style provides for the presence of panels in the bathroom or in the kitchen, then they must be covered with a protective layer of varnish. To extend the life of such cladding, it should also be treated with mastic and stain.

It is advisable to periodically update the interior decoration. To do this, every 5-7 years, a protective layer is applied to it, previously removing the old coating. The walls of the premises can be sheathed with boards both vertically and horizontally.

Can I make it myself?

Despite the fact that the modern market is represented by a chic assortment of block house, many owners of suburban housing prefer to make it with their own hands, rather than purchase it in finished form. At first glance, this may seem complicated, but if you have at hand a small workshop and a wood processing machine, then the process is quite feasible.

In the home workshop you can produce several types of panels: with imitation of timber, lining and euro board. Since the varieties of the wooden block house are not much different from each other, it is possible to produce panels of various designs without additional financial costs.

The process of self-production of a block house is carried out according to a certain scheme.

- First, the purchase of raw materials. It is better to choose wood of class A or B. For the manufacture of boards can be used both coniferous and hardwood. The main thing is that the wood be of high quality and free from defects in the form of chips and cracks.

- Then a log is cut into the bars. The sizes of future panels may be different, it all depends on personal preferences.

- The next step is drying. Wooden blanks are placed in special chambers, where they remain until the desired moisture level is obtained.

- After there is a cutting of grooves and spikes, after which the semi-finished product turns into a finished product. The board is re-trimmed in length.

- The final step is packaging. The resulting panels are sorted and laid in a thermal film.

Using this algorithm, it is possible to produce decorative boards both for your needs and for sale, which opens up opportunities for additional income. The cost of panels depends on the degree and quality of wood processing. For example, if you grind the material not only from the front, but from both sides, then its release will cost much more. In addition, the production of a complete set for a block house will require the presence of additional machines. The price of boards will also increase after they are treated with protective agents and antiseptics.

Given the above, before organizing an independent production of a block house, it is worthwhile to prepare an estimate and calculate financial costs. In addition to acquiring raw materials, you will have to equip the home workshop with the necessary equipment. Usually, a four-sided machine and a milling cutter are required for operation, the quality and type of panels will depend on its installation. If the machine was not purchased with a complete set of cutters, then they can be purchased separately. It is better to use automated equipment, however, it is worth considering that such a purchase will be expensive and entail considerable costs for electricity.

About what preparatory work includes the decoration of the house with a block house, see the next video.

What is a block house

Block house is one of the varieties of siding. The appearance of the casing is a convex oblong strip, in the set the material imitates a log cabin. The classic type of block house is made of wood and is one of the types of lining by the type of panel connection and common features. The wall, sheathed in a block with a house, has the appearance of a wooden house, built of logs, but devoid of the shortcomings of this type of buildings.

Advantages of the block house:

- In manufacturing, the material goes through a series of special procedures that reduce the ability to change linear dimensions, warpage, cracking and absorption of water.

- It has high mechanical strength, resistant to external influences and easily lends itself to various methods of local recovery.

- The low weight of the block house does not create an unnecessary load on the supporting structures of the house.

- Environmentally friendly material.

- It has high frost resistance.

- It has high heat-saving properties.

At the same time, there are some disadvantages:

- Flammable wood, even with regular impregnation with flame retardants, the risk of fire remains high.

- The material needs periodic maintenance - painting, impregnation, etc.

- The vapor permeability of the block house is very low, which forces us to take measures to enhance ventilation of the stitch space.

- Wooden block house is much more expensive than other types of cladding.

The properties of the block house are somewhat different from the usual types of wood cladding. Operating conditions, tested loads and temperature changes put forward certain requirements for the quality of the material. In the manufacture of wood, it undergoes special processing, deep drying, impregnation with compounds that reduce the absorption of moisture and the ability to burn.

The reverse side of the panel is flat with two or more grooves that compensate for dimensional changes during swelling and exclude surface swelling. The front side is a segment of a circle simulating the surface of a log in a log house. The connection is made in a tenon groove, available on opposite edges. A set of panels repeats a neatly made log house from a turned calibrated log, making the facade look neat and solid.

Types of block house - which one to choose?

A block house is a material of many varieties. The traditional look is wooden panels, according to the connection principle and the general appearance, are close to the lining.

They have several grades, shared by the quality of the material:

- E - Extra. Perfectly glued wood, straight layer, without knots and plane defects.

- A - Clean surface without damage, chips or nicks. A certain number of small adherent knots may be allowed.

- IN - Some defects, knots or slight flaws in the material are acceptable.

- FROM - There are a fairly large number of shortcomings. The material is used for finishing auxiliary buildings that are not visible from the facade.

In addition to the wooden block house, there are analogues from other materials:

- Vinyl.

- Metal (galvanized steel),

A panel may have one wave, two or more. Vinyl or metal panels typically have 2 waves. Wooden - basically, one, but options are possible.

The main advantage of alternative types of material is as follows:

- Resistance to water.

- Lack of burning ability.

- Do not rot, fungus or mold does not appear on them.

- Do not require care, painting, etc.

- They have many color options.

The disadvantages include:

- Vinyl siding is fragile at low temperatures.

- High coefficient of thermal expansion creates certain difficulties during installation.

- Low level of heat and sound insulation.

Vinyl and metal panels are much cheaper than wood, which to a large extent contributes to the greater popularity of these types of material.

Necessary installation tools and accessories

Installation of vinyl and metal siding is the same for almost all types and types of material. Therefore, the installation of a wooden block house will be considered, since there are fundamental differences.

For installation you will need:

- Electric drill.

- Screwdriver, screwdriver.

- Roulette, level, hammer.

- An awl for pricking the centers of the holes for self-tapping screws.

The list of tools can be significantly expanded, since the order of installation work largely depends on the condition and material of the walls.

As additional elements for a wooden block house, some metal elements can be used - window-planks, corner patch elements, spotlights, internal corners, etc. There are no special wooden elements; the adjustment of corners or joints is carried out by the usual carpentry methods.

Facade surface preparation

Preliminary preparation is the most important stage of work, on the thoroughness of which the durability and quality of service of the wall cake and cladding depend.

Procedure:

- Removing all foreign objects, dismantling air conditioners, drains, brackets, etc.

- Inspection and detection of all available deficiencies.

- Removal of old paint, exfoliated or crumbling areas. The surface should be completely monolithic and strong, all weak areas are removed as much as possible.

- Sealing of potholes or dents resulting from the removal of problem areas. Putty is used. In the presence of a large number of dents or at a large depth, continuous plastering of the surface is recommended.

- The last stage of the preparatory work is the application of a double coat of primer with intermediate drying according to the user manual.

Wall Pie and Ventilated Facade

A wall pie is a collection of all the layers that make up the wall of a house (device photo below):

- The inner wall itself is a building envelope.

- The warming material.

- Steam-waterproofing membrane.

- Lathing (or, as it is otherwise called, a subsystem).

- Ventilation gap.

- The outer skin (in our case, the block house).

The maximum composition of the wall cake is listed. In some cases, there is no need for a ventilation gap or insulation material. At the same time, if there is no ventilation gap, then the insulation is impermeable to steam (polystyrene or EPS). The absence of insulation, most often, requires a ventilation gap to organize the withdrawal of steam from under the casing.

Selection and installation of the crate

Lathing is a supporting structure for the installation of cladding, performing at the same time:

- The leveling function in the presence of defects in the geometry of the walls.

- Forming a ventilation gap.

- Supportive insulation material (not the most successful way, but used quite often).

The lathing design is a single or two-layer system of strips. The first layer is leveling, it forms a plane and supports the insulation. The second layer is installed across the first, it forms a ventilation gap and directly carries the casing.

As a material, wooden blocks or, which is much more effective, metal guides for gypsum plasterboard can be used. The battens are mounted on pre-installed brackets or direct suspensions for gypsum plasterboard. For fastening the strips, self-tapping screws with a tip under the drill are used.

Insulation Installation

Heater performs at least two tasks:

- Reduces the cost of heating a house.

- It eliminates the formation of condensation on the walls and the wetting of materials, leading to their destruction.

The choice of insulation is a rather difficult task. In order to use the most suitable type, one must understand the physical essence of his work. The main property is vapor permeability, i.e. the ability to let water vapor pass through the walls.

Impermeable types of insulation (polystyrene, EPS) do not require the formation of a ventilation gap, but to remove water vapor will require the creation of an effective ventilation system.

The insulation is installed on the prepared wall surface.

The most successful procedure:

- Installation of brackets for lathing.

- Laying insulation. The material is tightly mounted on the surface without gaps or gaps. Brackets are held through incised sections of the insulation. If necessary, fill the gaps with foam.

- On top of the installed insulation, a sealed layer of a steam-waterproof membrane is mounted, which protects the insulation from external (atmospheric) moisture.

- Waterproofing and vapor barrier walls

Hydro and vapor barrier is made using a special film (the best option is a vapor-waterproofing membrane). Protection can be installed either internally or externally.

- Indoor installation is carried out using impermeable types of insulation (polystyrene foam, polystyrene foam, EPSS, etc.). It plays the role of cutting off the internal steam from wall materials, preventing the appearance of condensation and wetting of the walls.

- External installation of protection is made on top of a heater. In this case, the film protects the material from external humidity, while releasing steam from the inside. This option makes it possible to remove moisture from the walls and keep them dry and healthy.

The film is installed in rows of 15-20 cm overlap with gluing the joints with special tape.

How to crop a block house at an angle

Trimming at an angle is done either with an electric saw installed in a special conductor with a marking. Such a device allows you to adjust the position of the saw so that the cut will be made exactly at the set angle.

Another option is the manufacture of a miter box - the simplest device in which a hacksaw moves in the grooves of two bars. For the manufacture of the miter box it takes very little time, but it will be necessary to precisely file the guide grooves.

How to dock panels on the outer and inner corners

The docking of the corner joints of the block house can be done in different ways:

- No special action is taken, angular connection is made by installing the corresponding profile additional element.

- A planed square beam is installed along the axis of the angle, against which the ends of the panels abut. The option is good, but you need to accurately calculate the thickness of the beam and the length of the panels so that the connection is as tight as possible.

- The panels are cut at 45 °, after installation, the panels corresponding to each other on opposite sides of the corner are connected with self-tapping screws. To do this, in one panel, a blind hole must be drilled at an angle into which the screw head will pass. In this way, the panels are pulled together, and a tight and neat connection is obtained. The holes should subsequently be plugged with stoppers and sanded flush.

- The most difficult option - the corners of the panels are sawed at 45 ° and precisely fit to each other without connecting to each other.

How to dock along the length

To dock a block house, you can use the following options:

- Straight vertical strips, on which the ends of all panels abut (an analog of the H-bar for vinyl or metal siding).

- Tight end-to-end docking (requires precise cutting at 90 °).

- One end is trimmed at 90 °, the second is also trimmed at 90 °, but in the opposite direction. The joint can be tightened with a self-tapping screw, providing a strong and tight connection. The screw is screwed at an angle, the hole is closed with a stopper and sanded flush.

Methods of securing a block house and the procedure for covering a house

How to sheathe a wall with a block house? Panels can be mounted in various ways:

- Through fastening through a front surface. The easiest way, but the appearance will be spoiled by the presence of hats of nails or screws.

- Fastening with threaded screws. After installing the next panel, the screws are not visible, which will greatly improve the appearance of the blade. The disadvantage of this method is the need to screw the screws into the edge of the tenon, which will cause a loose connection, you need to trim the counterpart in the places of installation of the screws, cleavage of the tenon is possible.

- Using Clamps. The easiest and most reliable way. The fastener tab is inserted into the groove, the clamp is screwed or nailed to the crate. The connection is tight, durable and non-destructive.

The panels are mounted with a spike up or down:

- The first option is used if fastening is done on screws, the second - on clamps.

- The first panel is installed with a small gap between the supporting surface to form a ventilation gap.

- A similar gap is made at the top of the web so that air under the skin can circulate freely. The connection in the tenon groove should be done as tightly as possible, avoiding gaps in which moisture can accumulate.

- When connecting, do not hit the panel hard with a hammer, as there is a danger of flattening the spike or groove and complicating the connection of the next panel.

Gable Trim Technology

Before starting work, you should consider the layout of the panels to get a symmetrical pattern. All end connections are best done in one place, so that the installed symmetrically vertical strips create a certain decorative element.

This is especially important with a large area of the pediment, when the panel length is not enough. Trimming panels at an angle can be done both on the ground and right in place, for greater accuracy, but this option is possible in the absence of a soffit or an unshielded roof overhang.

A block house is a natural material that allows you to simulate a log cabin with a high degree of realism. Accuracy, dimensional accuracy and ease of installation make this cladding one of the most preferred materials, and the ability to periodically tint the canvas and update the facade of the house allows you to constantly have a new look of the walls, which is unattainable when using other types of cladding. High quality material contributes to a long service life of the casing.

Environmental friendliness. Since the block house is made of natural wood that has previously been dried, the main advantages of it can be attributed to environmental friendliness. The coniferous house block has high strength properties, allows you to maintain indoors good microclimate and of hardwood, it has good moisture resistance and hardness. Due to the relatively high content of natural resin in the materials, a natural waterproofing is created, which increases the life of the structure, and due to its resistance to decay, the product can be placed in a humid environment,

Environmental friendliness. Since the block house is made of natural wood that has previously been dried, the main advantages of it can be attributed to environmental friendliness. The coniferous house block has high strength properties, allows you to maintain indoors good microclimate and of hardwood, it has good moisture resistance and hardness. Due to the relatively high content of natural resin in the materials, a natural waterproofing is created, which increases the life of the structure, and due to its resistance to decay, the product can be placed in a humid environment,