When we buy a new house or just make repairs in the apartment, the question naturally arises of how and how to finish the walls in the kitchen.

Of course, now on the market there are a huge number of different finishing materials that have a long service life, are easy to maintain and install. And in order to buy high-quality finishing material, it is sometimes necessary to incur considerable financial costs.

But what if the consumer wants to save on finishing materials? In this case, a relatively new material will come to the rescue - MDF wall panels. These panels are not inferior to their counterparts, although they have a price several times lower.

MDF panels have aesthetic appearance, long service life, and their cost is quite affordable - this is what attracts people to use this type of decoration material.

Another plus of MDF panels is the ability to widely use for decoration of any - both residential and non-residential - premises with various operating conditions.

A few words about creating panels

MDF sheets made from fine wood shavings or, simply, wood dust. This wood shavings are pressed into very dense canvases under the influence of high pressure and temperature. Wood chips are glued together with the help of lignin, which is released when the wood is heated.

The end result is a panel that has a density higher than all familiar fiberboard sheets. Himself MDF sheet is very similar to a solid wood. The thickness of the finished panels can be different, but not less than 16 millimeters.

See a selection of photos of cork wall decoration: many options for original and high-quality decor in any room of the apartment.

Find out in this article which non-woven or vinyl wallpapers are best suited for a child’s room or bedroom. Comparative characteristics will make the right choice.

Important and useful properties

Finished panels are very easy to cut.while they will not crumble or break.

Using the MDF wall panel for the kitchen, you significantly increase sound insulation.

Walls decorated with such panels They look very aesthetically pleasing and even resemble wood.

This material has high moisture resistancewhose level can be seen on the packaging. For example, if a drop is shown on the package, the manufacturer thereby informs the buyer that these panels have the highest moisture resistance.

Recently, more and more panels appear on the market, which have fire impregnationthat is, they are fire resistant. It is these MDF panels that are best suited for the kitchen.

Due to fluctuations in temperature and humidity, wall panels change their size, but these changes are insignificant, such as those changes that occur with PVC or fiberboard under the influence of the same adverse factors.

MDF panels perfect for decorating any roomwhether it is a corridor, a bathroom, an entrance, a room, a balcony or even an office. It can be argued that this finishing material will look good in any room, but it is especially suitable for the kitchen.

Advantages of MDF as a finishing material

Finishing work does not require high professionalism from the master. There is also no need to use complex or special equipment. To carry out the work, a set of ordinary tools that are in every house is enough.

Before finishing with this material walls do not need to be prepared in advance: smooth, remove paint, wallpaper, plaster.

MDF panels are very easy to install and have a low cost. All this allows you to reduce the time for wall decoration, as well as save money.

Due to the fact that for the production of MDF panels do not use various substances harmful to health (resins, glues, phenol), this allows the use of panels in places with increased requirements for hygiene and environmental cleanliness.

MDF paneled walls do not need complex and frequent care. It is enough to wipe them once a month using any detergents without abrasive substances.

MDF panels are universal. They can be used in all places: in the kitchen, in the living room, office, office.

The walls, which are decorated with MDF panels, will have high heat-insulating and sound-absorbing characteristics. And the room itself after the repair will have a very aesthetic appearance.

Panel Installation

These instructions will help you to do your own home decorating MDF panels.

We will consider those basic steps that a wizard should take in the following sequence:

- Expand the MDF panel to the size of the wall. The finished strip should be sized so that its lower part overlaps the countertop. The upper part should go slightly beyond the edge of the box.

- If there is an extractor hood in the room that is finished with MDF, then between this hood and the sheet itself there should be a free piece of wall. This free space can also be masked. To do this, you need a size with a small margin, both in height and in width. Do not be afraid that this piece will stand out, because its edges will hide the hood.

In conclusion, I would like to say that MDF panels are a wonderful finishing material. They are produced in different colors, therefore the color of the panels can be selected in any color scheme and for any design.

It is also worth noting that the MDF panels economical and have enviable durability.

If you decide to sheathe the walls of the kitchen, then you will not find a better option than MDF panels.

Read about how wall pasting is performed with non-woven wallpaper - all the secrets and subtleties of the technology are described in detail.

Find out here how to connect a faucet in the kitchen quickly, easily and without much hassle.

Using our instructions, you will understand that they are very easy to install, and we are sure that you will have no difficulties during their installation. For lovers, “it’s better to see once ...” we offer you to watch a video instruction on the use of wall MDF panels for finishing a kitchen apron:

Design of a kitchen room with MDF panels (selection of photos)

Modern material is made in different styles and with different textures. One of the demanded are laminated or veneered models that are made under natural wood: pine, alder, mahogany, maple. The surface can be any - gloss or matte, optionally decorated with an image (photo printing or 3D effect).

In the interior of the kitchen, MDF panels can be used for full or partial cladding of walls, ceilings and other surfaces

The panels made "under a stone" are not inferior. The material is performed in different interpretations, there are even models for metal or glass. “Openwork” sheets look beautiful and neat. If desired, they can be combined with any finish. Using MDF panels for the kitchen is beneficial, as it is not only practical, but also very beautiful. Natural wood can crack from moisture and steam, this can not be on artificially created smooth panels.

MDF material - what is it

What does MDF mean? The abbreviation is translated as "finely divided fraction." In the manufacturing process, wood fibers are used, with average density indicators. They are pressed together under high pressure and temperatures. To make the panels stronger, there is a binding component in the composition - resin. Models of the standard type are manufactured at the factory, but you can get the necessary sizes for an individual order.

Wall panels are sold fully ready for installation and can be painted, laminated or veneered

There are certain GOSTs according to which MDF passes as environmentally friendly raw materials, ahead of many types of wood.

Advantages and disadvantages of MDF as a finishing material

MDF panels for the kitchen have the following advantages:

- for installation it is not necessary to pre-prepare the surface,

- the finish is perfectly polished, does not crumble,

- environmentally friendly material, does not harm human health,

- it is quickly and simply washed from dirt and dust, and during installation there is no debris and waste,

- good price-quality ratio, availability for anyone who wants to make repairs,

- Finishing can be done on their own, without the involvement of craftsmen.

MDF panels are available in a huge assortment of design solutions - you can choose imitation stone or wood, or choose material to match the countertops

There are also disadvantages:

- the panels are not "friendly" with moisture in large quantities and negatively perceive temperature changes,

- if you do not cover the material on top with a special fire fighting device, there is a risk of fire,

- MDF sheets of small thickness can easily be damaged as a result of transportation or mechanical stress.

Such panels are equally well suited for walls and ceilings, while their installation does not require careful alignment of surfaces

Types of panels

According to their technical characteristics, panels can be divided into such categories.

- Laminated - there is a PVC film on the surface, such a coating is resistant to pollution, ultraviolet and has different structures.

Laminated products often repeat the color and texture of natural wood.

All-pressed panels have a smooth surface without decorative finishes and are used when it is necessary to create an unusual interior - such panels can be painted in the desired color

The surface of veneered panels is often indistinguishable from real wood.

Panel panels can often be found in classic interiors.

The surface of the painted panels can be matte or glossy.

Moisture-resistant panels are an excellent alternative to ceramic tiles.

MDF panels with photo printing

Equipped kitchen apron - it is convenient, practical and beautiful. In the process of cooking, splashing of fat or liquid may occur, so this area should be easily washed, neat and always maintain a neat appearance. Photo printing is original, your kitchen will be unique, because you can choose any image. How is it applied to the surface of an MDF board:

- A film with a pattern to stick to the surface of the panel is an inexpensive and short-lived method. A little humidity and temperature difference - and it can come off.

- The image is glued onto acrylic plastic and covered with varnish - the quality is better, but the method is more expensive.

- The film is applied to MDF, several layers of varnish with gloss are applied on top. Often used "hot cladding."

When buying panels with photo printing. it is worth finding out by what technology the pattern was applied on the MDF

MDF kitchen facades can be matte, glossy or embossed (bamboo, stone or wood). There is a minus: the surface is difficult to clean from grease and dirt.

Other

Panels from this material are classified into several categories:

- Large sheet panels.

Sheet material used for seamless wall cladding

Rack panels in shape resemble a wooden lining and often imitate it.

Square panels look interesting on the ceiling

Choose a design

Kitchen panels from high-quality MDF are distinguished by a large assortment, different designs. You can buy for every taste: ash, wood shavings, imitation stone, brick. Focus on a well-known manufacturer: this will always help you choose a good material.

Wall panels must be selected taking into account the design of the kitchen as a whole and the headset in particular - you can focus on the color and texture of facades, countertops, flooring or curtains

Before opting for a separate option, consider the type of coating with which the plates are produced:

- laminate,

- paper,

- veneering

- water repellent surfaces.

It’s worth choosing according to your design and type of room. Refractory water repellent coating is ideal for the kitchen.

Interesting solutions in the interior design of a private house and apartment (selection of photos)

Thanks to the large assortment, you can beautifully decorate any room, and the variety of textures helps to create truly stylish compositions. Textures “under a tree” or natural stone look spectacular. When choosing MDF sheets, consider the functionality of the space and zoning. If the kitchen is made in a classic style, you can focus on brightness, add creativity. The combination of light and dark shades looks good.

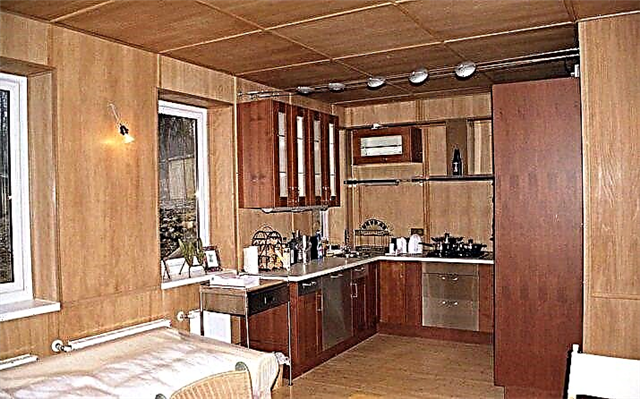

A successful combination of solid wood worktops and wall sections in the dining area with wood paneling

In the kitchen combined with the dining room, you can combine the lining - the lower part is decorated in dark color, add pastel or on top. You can use a wooden plank to emphasize the contrast. Striped trim visually expands the space. A good option is laminated panels under natural wood or stone. Veneered slabs are close to the tree in structure - they look spectacular and beautiful.

The classic solution for the interior of the kitchen is a dark bottom and a light top

Using MDF panels you can create a unique and extraordinary interior

MDF boards are of good quality compared to ceramic tiles - they are easy to care for and look much more spectacular and more expensive. If you select several options for shades, you can interestingly zoning the space, highlight the area for lunch and cooking. Partitions decorated with wall panels look good. Here you should prefer veneered or varnished surfaces. Kitchens from MDF panels with photo printing look very original, photos of which can be viewed for inspiration on the Internet.

Wood paneled decor in the kitchen dining area

How to choose a good panel from MDF

The material is relatively inexpensive, but it is important to pay attention to quality. How to understand what material is considered good:

- There must be a quality certification - you have every right to ask for a document at the time of selection. If it is, then the material contains no harmful components (resins and formaldehyde).

- There can not be many defective elements in the party - this indicates a low quality.

- The colors of the products should be the same, and the coating should be uniform.

Well-known manufacturers, as a rule, value their reputation and produce quality products. It’s better to overpay for a brand than run into a material that will wear out after a while and start to smell like formaldehyde

MDF boards are distinguished by good characteristics, naturalness and safety.This is a good option for finishing the kitchen surface, which is not only high-quality, but also very attractive in appearance.

General characteristics

MDF boards are made from waste wood industry. This is a small chip that is pressed with a binder, wood glue and lignin. MDF is a more environmentally friendly material than particleboard. The formaldehyde emission class is E1, therefore, it is safe for human health, like a natural tree.

On sale you can find panels that are completely ready for installation: laminated, veneered or painted. Which ones are more to your taste.

But often for an apron the laminated option is chosen standard sizes: 4 × 2440 × 60 centimeters. For wall cladding, it is better to select wall panels for the kitchen from MDF of greater length. For example, the manufacturer Egger offers a material length of 2700 centimeters.

The advantages of MDF wall panels for the kitchen are many, it is not in vain that they can be so often found in the kitchen interior. But the main advantages include:

Resistance to humidity and moisture. In this criterion, the tree loses much to MDF.

Resistance to humidity and moisture. In this criterion, the tree loses much to MDF.- Installation is not required from the master to carefully level the mills, you can quickly install them with a minimum of building knowledge and skills, in the case of glass and ceramic tiles, laying yourself is extremely difficult.

- Strength. The material easily withstands random impacts, as its density is high.

- Easy care. Washing MDF is very simple, even simpler than wood, glass or tile, which has many seams.

- Design ideas. You can take imitation of stone or wood, material to match the kitchen countertops and any other options.

- Low cost in comparison with stone, wood, agglomerate or porcelain stoneware. Wall panels can even be placed with a gap on the crate - this allows you to mount ventilation or electrical wiring under them.

- If you trim the rest of the walls in the kitchen with MDF panels, then it will become much warmer and quieter.

Of course, the ideal material has not yet been invented, these panels are no exception. Its disadvantages are as follows:

Panels do not tolerate high temperatures, it is undesirable to mount them next to the stove. From overheating, they are often deformed.

Panels do not tolerate high temperatures, it is undesirable to mount them next to the stove. From overheating, they are often deformed.- The ends are their weak point. If they are open, moisture may enter them. They are subject to mechanical damage.

- Instability to damage with sharp objects and scratches. If by chance it is easy to touch the wall with a knife, then nothing terrible will happen, but if you press with force, then the upper decorative layer will peel off.

- Unnaturalness. MDF panels still lose in this regard to natural stone or wood, even if they can be very high-quality photo printing with the image of these natural materials.

Despite the disadvantages, the panels are in demand, because they have much more advantages.

How to choose the right

It is worth buying material from well-known manufacturers who have the appropriate quality certificates. These include the German brand Egger and the Russian Kronospan. People prefer to overpay for a brand than to purchase low-quality products with high formaldehyde emissions and insufficient density from a little-known manufacturer. In the hardware store, you need to ask for all the documents confirming the originality of the panels to make sure that they correspond to the desired class.

It is worth buying material from well-known manufacturers who have the appropriate quality certificates. These include the German brand Egger and the Russian Kronospan. People prefer to overpay for a brand than to purchase low-quality products with high formaldehyde emissions and insufficient density from a little-known manufacturer. In the hardware store, you need to ask for all the documents confirming the originality of the panels to make sure that they correspond to the desired class.

Before buying, you need to take measurements, to decidehow much material is needed. For example, a corner long or U-shaped kitchen will require at least two panels. If you are confident in the accuracy of measurements, you can order cut sheets in sizes at the store. But often an accurate fit is carried out at home - for many it is more convenient.

By thickness, it is better to choose sheets with a thickness of four millimeters. This material will be more resistant to wear and moisture, but will not interfere with the installation of kitchen cabinets.

More sheets are selected taking into account the kitchen interior and the design of the headset. You can navigate by the texture and color of countertops, facades, kitchen furniture, floors or even curtains.

With a light apron, the kitchen space always looks visually larger. And in the dark, the space will be more chamber, but this technique is more suitable for large rooms. On the dark walls, any dust, stains from water, greasy spots will be noticeable - this is also worth considering when choosing.

If you plan to purchase panels with photo printing, then colorful designs can overload the interior. Types of cities, vibrant flowers, vegetables and fruits are good accents when the overall kitchen environment and the facades of the headset are distinguished by their laconicism. If the interior contains colorful curtains or wallpapers, it is better to choose an apron without photo printing, but with a traditional imitation of wood.

If you plan to purchase panels with photo printing, then colorful designs can overload the interior. Types of cities, vibrant flowers, vegetables and fruits are good accents when the overall kitchen environment and the facades of the headset are distinguished by their laconicism. If the interior contains colorful curtains or wallpapers, it is better to choose an apron without photo printing, but with a traditional imitation of wood.

When purchasing sheets with photo printing, you need to find out immediately by what technology the image was applied to the coating. There are only four basic application technologies:

- Drawing on a plate in ink. The price of such material is minimal, but the pattern is not particularly resistant.

- The image was applied to a film, which was then glued directly to the MDF.

- The picture was printed on acrylic, then glued to the plate.

- Hot cladding: the picture was applied to the plate, and then protected with a special thermoplastic layer.

In the last two cases, the price of the material is much higher, but the quality is at an altitude. If you do not want to change the panels in the kitchen after a year of operation, it is better to immediately buy high-quality material that will last a long time.

Installing an MDF apron

If the panels have already been purchased, then you can find out how to fix them correctly without the help of specialists. In fact, there is nothing complicated and with a responsible approach, all the work can be done in a couple of hours.

First, they mark the walls, calculate the amount of material. Cutting the apron must be done independently with the help of an electric logotype, if this service was not ordered in the store. Under the hood, you need a stove of a higher height. Often, they do not install MDF here, but select a neutral background material: a glass or metal screen or tile. With a clear glass, the apron will work very well.

First, they mark the walls, calculate the amount of material. Cutting the apron must be done independently with the help of an electric logotype, if this service was not ordered in the store. Under the hood, you need a stove of a higher height. Often, they do not install MDF here, but select a neutral background material: a glass or metal screen or tile. With a clear glass, the apron will work very well.- When the panel is cut in the required size, it is prepared for installation. Cut the required holes in the places where the sockets will be located (if any). Usually, three or four outlets are located near the working area, their location is accurately measured, then outlined in shape, cut out.

- Install the mounting plate, which serves as a backup for the apron. If the lower cabinets of the headset are already in place, then there is no need for a backup.

- Next comes the installation of plates. The panels are fixed with screws or glue. Each fastening technology has its fans and opponents.

Special attention should be paid to the choice of the method of fixing the plates to the wall. Installation with self-tapping screws allows, if necessary, to quickly replace the panel. Such a mount provides for marking for self-tapping screws. Each fixture is located in steps of 50 (on average). The holes in the wall are made in advance, the dowels are inserted there, then the screws themselves are screwed in, tightly pulling the plate. Hats are hidden with special decorative caps, which are best to buy immediately with the sheets in order to pick them as matching as possible in tone.

Special attention should be paid to the choice of the method of fixing the plates to the wall. Installation with self-tapping screws allows, if necessary, to quickly replace the panel. Such a mount provides for marking for self-tapping screws. Each fixture is located in steps of 50 (on average). The holes in the wall are made in advance, the dowels are inserted there, then the screws themselves are screwed in, tightly pulling the plate. Hats are hidden with special decorative caps, which are best to buy immediately with the sheets in order to pick them as matching as possible in tone.

When mounting on glue, holes are not required. It is only necessary to prepare the holes for the outlet. Special glue is taken. You will also need a special glue gun, with its help it will be much easier to apply glue. Distribute it on the back of the sheet horizontally every twenty centimeters. Then the apron is applied to the wall, fixed with spacers for fourteen hours.

After all these manipulations required sealant joints between pedestals and an apron and close them with a decorative plinth. Then installation of a sink, sockets or roof rails is already carried out.

Material cost

Of course, the issue of price for many may be a decisive factor. Full-size plates with photo printing, which are sixty centimeters high, can cost about two thousand rubles.

Of course, the issue of price for many may be a decisive factor. Full-size plates with photo printing, which are sixty centimeters high, can cost about two thousand rubles.

The cost of options with imitation of stone, wood, brick and tile varies from a thousand rubles to three thousand. Here a lot will depend on the thickness of the sheets (two or four millimeters).

If the installation is on glue, you will need to buy it in a special tube, on average, the price for it is three hundred rubles. When mounting on self-tapping screws, it is required to purchase the self-tapping screws themselves and caps for their hats.

In general, MDF panels for the kitchen are a good choice if you want to create an interesting design on your own without any special financial costs. With them, the kitchen will immediately become more comfortable, it does not matter if only the working area or any whole wall of the room is decorated with stoves.

MDF board characteristics

The material enters the construction market in the form of plates of various sizes, consists of fine wood chips and a special lignin component. In the manufacture of panels, the feedstock is pressed under the influence of high pressure and temperature. To improve the strength characteristics, binders and resins are added to the base composition.

Length is from 130 to 260 cm, width - 15, 20 or 35 cm, thickness - from 5 to 15 mm. In terms of technical characteristics, an MDF-board is similar to wood, and surpasses it in some qualities.

The surface imitates the texture of natural finishing materials (stone and wood). The plate is fixed to the base using special glue or staples on the previously installed crate. To facilitate fixation, grooves and ridges are made in the edges.

Advantages of MDF

Advantages of panels over other finishing materials:

- Lack of work on preparing the surface before installing the plates.

- Excellent thermal insulation performance.

- The material is used not only for the design of the working area, but also for the decoration of other walls.

- The ability to mask utilities or wiring under the crate.

- High rates of material strength, ease of processing (cutting and grinding).

- Safety for health.

- The surface of MDF has water repellent properties.

- A wide selection of colors and shades.

- Resistance to mechanical damage.

- Quickly cleaned of any contaminants with detergents.

- A wide range of products, affordable cost.

- Simple and quick installation of MDF panels for walls in the kitchen.

- Decorative boards do not need constant care, and after wet cleaning, their surface acquires its original appearance.

Important! Among the shortcomings of the material, attention should be paid to the possibility of scratches when cleaning with abrasive particles. The panels are not installed above the gas stove, because exposure to high temperatures can cause them to deform. The ends must be protected from moisture by a special metal profile.

About the advantages and disadvantages

The most important advantages of this material include its environmental friendliness, which is not inferior even to wood. And this is quite natural, because they produce fiberboards only from natural material, namely from fine-grain wood waste that has been cleaned of extraneous debris.

The smallest sawdust is heated and then pressed. A substance called lignin is released from heating sawdust and is a natural binder.

What are the characteristics of the MDF board:

- moisture resistance (a plate with a dense structure does not pass water as fast as chipboard, which is considered a material with a higher porosity),

- high mechanical strength, identical to the strength of the furniture board and natural wood,

- heat resistance (plates, of course, are not fireproof, but will not dry out from direct sunlight),

- insulating properties - MDF sheets reliably protect from noise and retain heat,

- plates look spectacular (especially glossy) and are suitable for the implementation of any design decisions.

A material with such parameters is ideal for finishing a kitchen - a room in which there is often both high humidity and high temperature. And the variety of MDF panels in shades makes it possible to select them for absolutely any kitchen interior.

Disadvantages

But this material also has drawbacks - the material is not fireproof and not so moisture resistant to withstand prolonged contact with water - it is deformed.

Another disadvantage of this material is its ends, they are not protected by anything and the junction always requires additional processing manually or using special profiles that can protect the material from moisture.

How to improve the quality of the material

If this material is covered with any paintwork material, PVC film, plastic, veneer or acrylic sheath, then its performance will significantly improve - it will become resistant to fungal infections, as well as to the effects of other putrefactive microorganisms.

The most resistant to surface damage is the plastic coated MDF material. The most environmentally friendly will be a sheet of MDF, lined with natural veneer, and the most beautiful - with a pattern or with photo printing.

Classification

For the manufacture of slabs, fiberboards are used, they just fit any size. Plates are divided into groups according to their shape and size.

Square plates

They can also be used to decorate the ceiling. For this, an MDF sheet of the largest area is taken and cut according to the parameters provided by the customer.

Wall panels are selected in size, from 1040 mm to 2800 mm, so as to avoid joints as much as possible.

Thickness

MDF boards are also different in thickness. The thinnest have a thickness of 5 mm to 9 mm, they are lightweight and very convenient for installation, but they do not differ in special strength. Such material goes on the facade of the furniture or on the decoration of the kitchen ceiling.

Medium-thickness plates, from 10 mm to 18 mm, are usually used in wall decoration, in the manufacture of doors and for furniture frames. This is a fairly strong material, but their thickness, albeit slightly, will take up the useful space of the room.

The thickest, and therefore the most durable plates, from 19 mm to 38 mm, are used mainly for furniture production, as well as in large rooms that are sheathed for the purpose of additional insulation.

Texture

In addition to length and thickness, the MDF wall panel for the kitchen also varies in texture. It can be both smooth and embossed. A smooth surface, and especially glossy, will visually increase the area of the room, which is important in a small kitchen. But the textured relief cladding has its advantages - it looks more impressive, and various minor defects on it are almost not noticeable.

This material makes it possible to roam around design ideas - you can try to combine different colors and different textures, and also try to make non-standard laying of MDF boards during installation (for example, diagonally).

And for those who do not count on their design talents, there are ready-made rather original proposals, including MDF boards with a 3D effect.

Full cladding - is it good or bad?

It would seem that repair is a repair, and it is better to change the entire surface. But with regards to the kitchen, this is not entirely true, because as a rule, this room is small, and if she is sheathed in this way, the kitchen will look like a cramped box.

There may be options - you can try to solve the problem of cramped space using a game of material of different colors, a combination of textured and smooth tiles or make an interesting styling: the floor is finished with square tiles, the walls with clapboard in different colors, and the ceiling can be made from panels without seams.

But such experiments are recommended to be done nevertheless in a country house, and in an apartment, kitchens are often only partially finished with MDF panels.

Ceiling

It is also a surface that can be covered with clapboard, the only condition for the ceiling is light tones of the finishing material. It can be monophonic or imitate a stone of light shades or some original relief. But the same covering for the ceiling and walls should not be selected, the kitchen looks much more attractive, in which its different parts look different, both in texture and in color.

How to make the lining of the lunch area?

Laminated or veneered MDF boards are beautiful in structure and have a pleasant natural shade of wood, which is very suitable for arranging a lunch area, where, in this way, a warm homely atmosphere and comfort are created. Such material in this case will be much better than ceramic tile and much more practical than wallpaper.

The dining area is usually located at some distance from the stove and from the sink, and therefore there is no need to be afraid of excessive moisture and temperature. If desired, you can arrange the cooking zone and dining area in different tones so that they are demarcated visually. And if the size of the kitchen allows, then this separation can be not only visual - between the two zones you can build a partition, for example, from MDF sheets under a tree.

The partition itself, according to your desire, can be decorated with expensive veneer, as well as a simple varnish coating or realistic photo works. Openwork partitions from the same material, but processed by laser cutting, are very effective.

How to mount a kitchen apron?

Sites located in the middle of the kitchen walls (between the upper and lower rows of furniture) are the main working area of this room. And this means that it is on this part of the kitchen walls that the greatest influence is exerted by moisture and heat. For such a finish, MDF boards should only be selected moisture resistant or else they can be closed using a glass screen.

There is the most reliable way in which it is recommended to finish the interior kitchen. These are special MDF skins with a heat-resistant plastic coating. In addition, taking into account the specifics of the room for which these stoves are intended, they are made with a rich decorative design, perfectly suited for the kitchen area.

The best option for fixing wall panels for a kitchen apron is a crate, for which it will be convenient to hide the various communications necessary for the operation of kitchen equipment and the wiring with which the working area will be highlighted.

How to make the skin yourself

MDF boards can be mounted in one of two options - either with the help of a frame, or with the help of some construction glue. Using the frame is considered a more environmentally friendly option, because in this case you do not have to use any chemicals, because from high temperatures they can begin to release hazardous fumes into the air.

But in the kitchen there is always exhaust ventilation, and therefore harmful substances will be immediately removed, so you should not refuse from the adhesive installation method for covering one or another surface.

On glue

This installation method is suitable for all types of MDF panels, although it is better to fix thin and medium plates in this way, of course. It should be borne in mind that this option is possible only if there are only small defects on the surface that extend beyond the wall plane by a maximum of 3 mm.

When work is underway with glue, you should take care of your protection - purchase a respirator and rubber gloves, in addition, air must flow into the room.

Finishing the kitchen using MDF boards is a fairly simple task and will not take much time. First of all, the working surface should be cleaned of the old coating. No paint, wallpaper, or any other material should remain on the surface.

Next, the surface is primed. This solves the issue of eliminating fungus and mold, and also improves adhesion. If the lining is carried out throughout the kitchen, then the metal profile must be attached with screws at the bottom of the wall, to the floor itself. The first bar is measured with a level and, thus, the procedure for aligning all other rows and mounting the baseboard is simplified.

Features of glue application and installation

The base is covered with glue either by the dotted method, or by strips in the form of zigzags. When a large sheet material is attached, the glue is also applied to the surface to be glued, and if the strip is very small, only glue can be applied.

You need to start mounting from the corner of the kitchen. The first panel should be pressed to the surface, aligned vertically and horizontally, using a level. Then you need to tap the panel with a special rubber mallet so that it fits snugly. Next, the remaining panels are attached.

MDF in the interior of the kitchen

Laminated boards have a different texture. When laying in the kitchen, such products can be combined, making one of the walls dark and the second light. Tiles with imitation wood or stone, laid on the entire surface of the walls, look original.

Finishing materials are combined in the horizontal direction. In this case, at 1/3 of the height of the room, dark boards are fixed under a stone or wood, then options with a light surface are fixed. At the junction of elements with different tones, a special plank of wood is installed.

Tip! You can combine the panels as follows: at the lower level, wide boards are mounted in the vertical direction, the second half of the wall is laid out horizontally. The joints are masked by a decorative strip.

MDF with imitation of natural stone or wood texture are successfully combined with other finishing materials. Such products are installed in the lower part of the wall, wallpaper with a pattern is glued to the ceiling. A decorative strip is applied at the joints.

How to choose a panel MDF for the kitchen

When choosing a quality material, you need to pay attention to the following points:

- To finish the apron in the kitchen, choose plates with a thickness of at least 4 mm.

- Before buying, read customer reviews. It is worth choosing companies that value their reputation by producing high-quality finishing materials. The most popular companies are Latat, Kastamonu or Kaindl.

- When buying, you need to ask for a quality certificate, the absence of a document should alert: panels from unscrupulous manufacturers may contain hazardous formaldehyde resins and other harmful substances.

- You need to buy plates in special stores. The material should be stored in a dry room.

- Color and texture are selected for the design of the kitchen.

Installation methods for wall MDF in the kitchen

Decorating the kitchen with MDF panels is carried out in the following ways:

- on special glue,

- on a frame made of wooden battens or a metal profile.

The first method is suitable for decorating perfectly even walls. The surface is cleaned from the old coating (wallpaper, paint), cracks and cracks are closed, a primer is applied.

According to the instructions on the packaging, glue is diluted in a small container. The mixture is applied to the base surface using a notched trowel, the panel is pressed and fixed on the wall. The fastening of other elements is similar. A monolithic coating is obtained after joining all the parts using special grooves.

A popular way to install MDF panels in a private house is to install decorative material on a frame of wooden battens. To prevent the occurrence of fungus and mold, the wood is treated with special antiseptic impregnations from all sides. The elements of the lathing are fixed on the base surface using nails or self-tapping screws.

To create the crate, a metal frame from the profile is also used. Mounting parts are purchased with special hardware and fittings. The steel profile is fixed to the wooden wall with self-tapping screws. Dowels are used on concrete substrates.

In this case, a hole of the required diameter is drilled at the base, plastic fasteners are hammered into it, then the profile is fixed using the dowel and connecting element.

Important! If a long drill bit is used for holes, set the depth of penetration into concrete using a red thread or other stop.

Before starting the installation, the elements are cut to the required size with a hacksaw or circular saw. The first panel is installed in the corner of the room according to the testimony of the building level. Products are fixed on a metal crate with special fasteners (clamps and self-tapping screws). Laminated boards can be attached to wooden rails with brackets or small nails. Products are inserted into the groove and fixed with clamps.

Resistance to humidity and moisture. In this criterion, the tree loses much to MDF.

Resistance to humidity and moisture. In this criterion, the tree loses much to MDF. Panels do not tolerate high temperatures, it is undesirable to mount them next to the stove. From overheating, they are often deformed.

Panels do not tolerate high temperatures, it is undesirable to mount them next to the stove. From overheating, they are often deformed. First, they mark the walls, calculate the amount of material. Cutting the apron must be done independently with the help of an electric logotype, if this service was not ordered in the store. Under the hood, you need a stove of a higher height. Often, they do not install MDF here, but select a neutral background material: a glass or metal screen or tile. With a clear glass, the apron will work very well.

First, they mark the walls, calculate the amount of material. Cutting the apron must be done independently with the help of an electric logotype, if this service was not ordered in the store. Under the hood, you need a stove of a higher height. Often, they do not install MDF here, but select a neutral background material: a glass or metal screen or tile. With a clear glass, the apron will work very well.