In winter, garages built without the use of additional insulation do not warm up sufficiently. In order to comfortably be in the room and use it not only for parking the car, a comprehensive insulation of the garage should be performed. Depending on individual needs and technical parameters, you can choose the appropriate insulation option.

Types of insulation

To maintain the high temperature inside the building, it is recommended to sheathe the garage on both sides. If desired or not possible, it is allowed to insulate the garage only inside or outside. The type of suitable insulation depends on the type of construction, the materials used and the required temperature. It is possible to clad brick, concrete with various types of roofs, including frame, single-pitched and others.

Outside

External cladding of the garage is carried out only on separately constructed structures. In arrays where the external wall of the structure is internal for a nearby garage, this method of insulation is not possible. The process of insulation consists in covering the external walls with a heat-insulating layer and providing protection for the porous surface.

Walls

The bulk of the heat in the building is lost due to thin walls. Inside the walls can be sheathed in several ways. The most affordable requires the following steps:

- Walls are cleaned of old layers of plaster and paint. An uneven surface is treated with a cement-sand composition.

- After drying, the walls are covered with soil or an antiseptic to prevent the development of dampness and mold.

- Sheets of foam or other material are glued to the prepared surface.

- A stucco mesh is applied over the heat-insulating layer.

- The wall is covered with plaster and putty.

A more costly method involves the construction of additional partitions along each wall. The space between the walls and partitions is laid with an insulating layer, which minimizes heat loss.

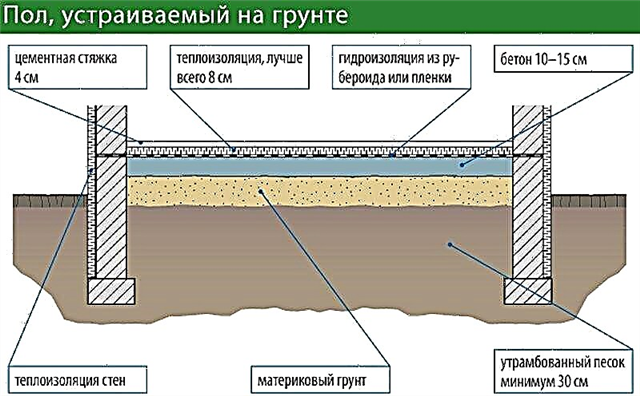

Thermal insulation of the floor in the garage building is carried out using expanded clay or polystyrene. The function of the coating is performed by a cement-sand screed. To lay the insulation layer, the following steps are carried out:

- A pit with a depth of about 30 cm is dug around the perimeter of the room. The base is leveled and several lighthouses are placed, after which the installation horizon is determined using the building level.

- The bottom is covered with roofing material or polyethylene. On each side, the material is bent 30 cm.

- Expanded clay is filled up or expanded polystyrene is laid to full depth. The surface is aligned with the beacons, after which they are removed.

- A reinforcement frame and a beacon profile are placed on top of the insulating material.

- A cement-sand screed is poured from a far corner. After pouring, the coating is leveled.

Goal

Even with a tight closure, a significant part of the heat leaves through the gate. If you completely sheathe the perimeter, but leave the gate, then the temperature in the room will remain almost unchanged.

To warm the flaps, their inner part is covered with polyethylene, after which a frame of wooden beams treated with an antiseptic solution is screwed to the canvas.

Heat-insulating material of appropriate thickness is placed inside the frame and glued to the inside of the door with glue. Docking seams overlap with foam. From above, the insulating layer is sheathed with lining or metal sheet.

Types of insulation

A wide variety of insulation materials are presented on the construction market, which differ in thickness, structure, flexibility, installation method and other characteristics. Before performing external or internal thermal insulation works, it is recommended to compare the appropriate insulation options and choose the optimal one.

When selecting material, it is necessary to provide the required amount to completely sheathe all surfaces. An integrated approach will help to choose the material with the best insulating properties.

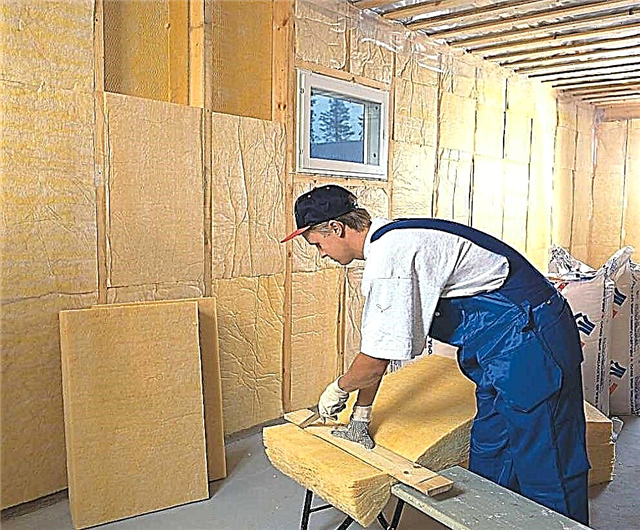

Mineral wool

Mineral wool, which is a roll-type material with a foil coating that reflects heat, is ideally suited for the inner lining of the building. Mineral wool is easy to install and does not create a load on the overlapping walls and roof. Mineral wool fibers provide free air circulation through the insulation layers, which prevents the development of mold.

Other advantages of mineral wool include: low thermal conductivity, soundproof properties, low weight, ease of installation.

Styrofoam

Polyfoam is considered a universal heater, which is mounted on any surface inside the garage. The material is not exposed to liquids, resistant to variable temperatures, does not decay and does not grow moldy over time. When interacting with polyurethane foam or glue, the foam does not collapse due to the absence of a chemical reaction. The disadvantages of the material are flammability and the threat of damage by rodents. To protect the foam, an additional protective finish is required.

Expanded polystyrene

According to the installation method, polystyrene foam has a number of similarities with polystyrene. Distinctive features are reduced water absorption coefficient and increased density. Due to the large thickness, polystyrene foam provides more powerful frost protection, but costs more than other materials.

Penoizol

Penoizol is an analog of polystyrene and is used for application to walls in a liquid state. The material absorbs liquid well, but does not accumulate it in itself, evaporating into the air. Penoizol is considered a hygroscopic vapor-permeable insulation with a burning class G-1. One of the competitive advantages of penoizol is the possibility of production directly at the place of work with subsequent application to any surface.

Glass wool

Compared to mineral wool, glass wool is cheaper, but it can only be used with protective gloves. Wool fibers are stiff and spiky, so disregarding safety precautions can result in personal injury. If liquid drips during installation on the surface of the glass wool, then it will have to be discarded, since it is not possible to dry it. After getting wet, the fibers lose their original characteristics and exude an unpleasant odor.

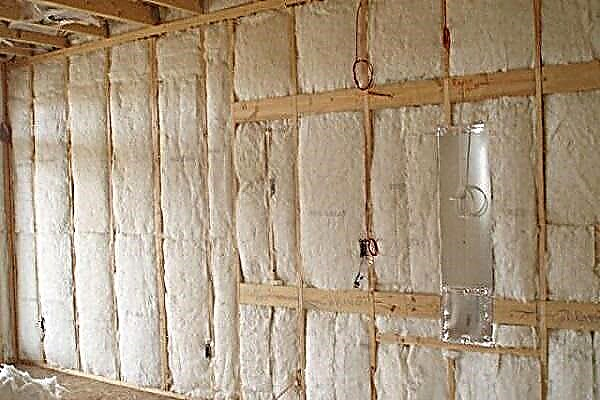

Polyurethane foam

Modern material is rapidly spreading due to increased resistance to external factors. Polyurethane foam does not lose its qualities when interacting with a liquid and, after drying, forms a dense hydrophobic coating. For applying the material, specialized equipment is required.

Installation difficulties are justified by tight connection with any surface and high-quality protection against heat loss. After installation, the polyurethane foam expands, all empty spaces and cracks are filled.

Warm plaster

The modified plaster consists of specialized fillers, including sawdust, polystyrene particles and expanded vermiculite. The aggregate of fillers gives the plaster thermal insulation properties. To get the desired result when decorating, it is necessary to apply a dense and heavy layer of plaster. To simplify, it is recommended to combine warm plaster with other varieties of insulation materials.

Heat insulating paint

To protect from cold weather and to give the garage a decorative appearance, liquid materials made from acrylic polymers are used. Natural pigments and synthetic rubber are added to the paint.

One coat of paint by thermal insulation properties replaces a layer of mineral wool with a thickness of 50 mm. Paint lays well on wooden, metal and plastic surfaces. After application, the paint forms a vapor-permeable coating and provides air permeability, preventing the waterlogging of the internal component of the structure.

How to insulate with your own hands

To ensure high-quality thermal insulation, it is necessary to correctly perform all stages of installation. First of all, surface preparation is carried out - bumps and cracks are repaired, primer treatment is carried out. Insulation is applied to the treated surface. To further fix the heat-insulating material, fasteners are used. The surface of the insulation is covered with plaster. If necessary, to give the surface a decorative look, coloring is carried out.

Condensation is the cause of corrosion

Thoroughly rolling the car into the garage, you snap the lock on the gate, contentedly head home through the snow crunching in the cold.

Meanwhile, you just yourself have created all the conditions for the favorable development of corrosion on the machine body.

The hot metal of the motor and the hot exhaust pipe will heat the icy air in the garage. But the opposition of heat and cold will be unequal. The engine will cool quickly.

According to the inexorable laws of nature, condensed droplets will appear on the cooled surface. Corrosion is taken over.

According to the inexorable laws of nature, condensed droplets will appear on the cooled surface. Corrosion is taken over.

But condensation does not only form on the machine. Treacherous drops will also appear on the ceiling, on the walls.

If the garage metalHe is doomed to rust with the machine.

On the brick walls, dampness will cause destructive mold over time, and on the wooden shelves of the tool rack will appear fungus.

Oddly enough, cars parked in open parking spaces in winter are not subject to external condensation. But the condensation process takes place in a closed cabin, these machines rust from the inside. That is why it is recommended to close the windows loosely, leaving slots for ventilation.

It’s unsafe on the street, but in the garage always do this.

Rescue ventilation

The first step to defeating condensate and corrosion is the ventilation device in the garage. In the opposite corners of the garage, two pipes must be led out.

The lower edge of one of them will be placed closer to the floor. This pipe will enter the room cold air. A short pipe near the ceiling in another corner will serve as a hood.

This simple, but reliable device will work flawlessly automatically, without fashionable fans creating a natural movement (convection) of air in the volume of the garage.

Convection will not allow condensation to form. Wet fumes just fly into the pipe. Exhaust gases, vapors of fuel, and other chemicals stored in the garage will go there too.

And now we turn to the most important thing - we insulate DIY garage. Here the situation is more complicated, but the task is quite affordable for an independent solution.

How to insulate a garage cheaply from the inside?

Warming do-it-yourself garage inside is an integrated and comprehensive enterprise. This is one of those works that must be brought to the end, otherwise your work and money spent on materials will be thrown into the wind in the literal sense of the word.

In the struggle for a comfortable car environment, it is absolutely pointless to insulate only goal or walls the garage. Insidious cold penetrates through any unprotected surface insulation.

After all, you can’t block the river by dumping only part of the dam.

Do-it-yourself garage insulation - photo:

Types of materials

How to insulate the garage from the inside inexpensively?

If you are planning insulate the walls of the garage, you should first familiarize yourself with some types of insulation materials. They are very diverse in properties.

Almost all heaters made from waste products from metal, glass, paper, chemical industry. Some of them are unsafe under certain conditions.

- Glass wool

Elastic, heat resistant, resistant to aggressive chemicals. It is made in the form of plates and rolls. This fiberglass insulation is effective, but potentially harmful for good health.

With any manipulations, microscopic, invisible to the eye, glass rises above the glass wool dust needlesbroken off from fragile fiberglass.

These dangerous sharp specks of dust irritate the skin and can seriously damage the eyes and lungs. With glass wool work with a respirator, gloves, goggles.

Glass wool is indispensable in places requiring thermal insulation from high temperatures. If installed in the garage bakeGlass wool reliably protects the walls from overheating and fire.

Mineral wool

It is made of molten natural stone, from slag waste from metallurgy. The properties are close to glass wool, but heat resistance mineral wool significantly higher. Available in the form of mats and slabs.

When heated to high temperatures (over 300 ° C), it releases hazardous to health toxic substances.

In many countries, some types of mineral wool are banned as being hazardous to health. But these prohibitions do not go beyond borders: in neighboring countries such cotton wool is produced and applied.

how insulation for mineral wool garage effective and safe.

Cellulose insulation

Eco-friendly, with good thermal insulation properties. Disadvantages: flammable, water permeable, prone to mold.

Expanded polystyrene

Suitable for warming the inside of the garage with your own hands. Not subject to water and mold. Not compatible with chemicals, high temperatures. Fire hazard. Some types of this insulation treated with flame retardants do not burn, but melt.

Manufacturers claim that the level of thermal insulation 10 cm layer polystyrene foam is equal to the thermal protection of a two-meter brick wall.

Exterior walls

How to insulate a garage cheaply? If the garage is narrow, we will not take away the meager internal space onto the crate, but we will transfer the structure to the outside.

In principle, the technology of work will not change in any way.

In principle, the technology of work will not change in any way.

Only insulation and siding materials need to be selected water resistant.

Mineral wool, for all its advantages, in this case will not work for us - it absorbs (accumulates) moisture.

Foamed in all respects plastic heaters: polyurethane foam, expanded polystyrene, expanded polystyrene.

For siding, we choose panels made of warm cellular vinyl or metal (aluminum, steel).

Comparing prices, calculating the available budget, let’s focus on polystyrene and profiled metal. After all, with one sheet of corrugated board, you can immediately close almost the entire wall of the garage.

Garage insulation foam

Foam boards - one of the cheapest and most effective heaters. But in the construction of modern buildings it is practically not used.

The fact is that this material has a large disadvantage - It is flammable. Burns like napalm. Do not extinguish with water. In addition, some types of foam break up into small granules over time.

However, the enticingly low cost attracts many private developers, for whom fire bans are not a decree. After all Styrofoam has undeniable advantages.

It is lightweight, waterproof, easy to cut and process, takes any form. Positive qualities include bacteriological properties polystyrene foam. It is not susceptible to decay, neither mold nor fungi on the foam will ever settle.

In a word, if you promise yourself to comply with all conceivable fire regulations, feel free to go to the store for foam boards for budgetary insulation of car storage.

At the same time buy a fire extinguisher with foam or carbon dioxide. God saves man, who save himself.

Garage Thermos

How to insulate a garage with foam?

With the help of cheap polystyrene foam (thickness. - 5 cm), inexpensive sheets of colored corrugated board and wooden beam (50 x 50 mm) we turn the old-fashioned iron garage into an attractive warm candy house.

- Timber. For processing the beam, used motor oil is finally useful. Impregnated timber will acquire water-repellent and antibacterial properties. In the old days, railway sleepers were treated like this.

True, from under siding the smell of engine oil will be heard for a long time. But in the garage this car fragrance will not bother you - we don’t sew a bath.

Walls. From the beam we build a horizontal crate on the walls. Cell pitch - for the size of foam boards.

By the way, if a wall sheet in size is more economical to install horizontally - this is what we do, only we make the crate vertical.

By the way, if a wall sheet in size is more economical to install horizontally - this is what we do, only we make the crate vertical.

We fasten the beam to the walls and roof with bolts through. We put washer-grovers under the nuts. The bolt heads are recessed into a tree.

Generously coat walls meerkat, the remnants of any unused paint, even if it has thickened. Smearing will serve as a farewell anticorrosive to the iron walls, as well as glue for foam.

On the crate, put under the level and fasten the sheets of corrugated board. At the corners we install at the ends we set the corresponding angular, at the ends - the finish profile.

Roof. When the roof device is installed, the corrugated board turns into a roofing material.

We lay the sheets on the roof so as to provide an unhindered drain of rainwater. On the crest of the gable roof we install a special corner profile.

If desired, on the roof you can lay professional sheets other than wall sheets of color.

Goal. As a rule, in standard metal garages, gates are pressed from a steel sheet, at the ends bent inward. We will insulate this space according to the already known technology “beam-polystyrene foam siding”. But for the inner lining we use not corrugated board, but a lightweight plastic lining made of cellular polymers.

Outside, the gate leaves are sheathed with the same plastic lining. We fasten it to the screws without the crate, directly to the metal of the wings.

However, even lightweight insulation will significantly add weight to the wings. If the hinges are weak, you will have to weld two additional ones on the top so that the leaves do not “peck”.

Dense building

how insulate do-it-yourself garage? Often garages are installed close. The side walls, it would seem, are not accessible for insulation. But there is a way.

Offer the non-standard solution to the right-left neighbors: limit the space between the walls and fill it up expanded clay all the way to the roof. It is best to brew openings with steel sheets, a wooden shield is short-lived.

Expanded clay - an excellent heater. It is not necessary to cover the backfill from rain and snow. Expanded clay "breathes", moisture falling into the backfill will quickly evaporate. You will have to insulate the back wall, gate and roof.

Finally:

Looking at a miracle built by your own hands, you will not believe your eyes. But there are a couple of bonuses.

Remember how many times you cleaned from rust and painted the outer walls of your metal garage? How many times did a battery sit in a frozen garage, did the transmission oil freeze? Remembered? Now forget about it forever.

Low temperature garage protection requirements

Garages are mainly built from cinder block, brick and sometimes metal products. The thickness of the walls made of cinder block or brick most often ranges from 120-250 mm. They practically do not protect the room from low temperature, so for comfortable operation they need to be properly insulated.

With internal insulation of the garage, you do not need to close all the holes - this will not improve the thermal insulation, but it can cause certain problems. Without constant ventilation, moisture from the air will condense on the metal, and it will begin to rust. In addition, ventilation prevents the accumulation of harmful gases in the garage.

Where is it better to insulate the garage - outside or inside

Many garage owners argue that it is better to insulate the exterior of the garage, interpreting this as saving space. But do not forget that some heaters release substances into the air that can damage health. Indoors, they should not be used, but for external thermal insulation they are perfect.

Another plus in favor of internal insulation - the environment is less affected by the materials used. After all, what is the use of insulation if it gets wet? With internal thermal insulation, such a development is ruled out.

Choose the right material

Most insulation materials are produced from industrial waste. To do this, use:

- Cellulose

- Glass,

- Various chemicals.

The less insulation costs, the more defects can be found in it.. There is a large list of common materials. When choosing among them the right one for your conditions, you need to consider both their positive properties and disadvantages.

Reflective insulation

The advantage of foil insulation is that heat is reflected inside the room. The thickness of the reflective layer can reach up to 50 mm. Such materials significantly reduce the heat loss of the garage, because they occur as a result of the loss of infrared radiation. But they are not able to affect the induction and convection losses of thermal energy, and this is a serious minus.

Warm plaster

If the walls in your garage are made of brick or cinder block, you can use heat-insulating plaster to insulate it. During its manufacture, the composition includes special additives that retain heat: vermicult, processed sawdust or expanded polystyrene.

This insulation has good thermal insulation properties, but in order for such insulation to be effective, it is necessary to apply a thick layer of material on the wall surface, which will increase the load on the garage structure.

Recommendation! It is advisable to use warm plaster as an additional insulation along with other heaters.

Warming paint

This material is made in the form of liquid polymers into which synthetic components are added. The resulting coating retains heat well. A layer of warm paint with a thickness of 1 mm retains heat in the same way as a layer of mineral wool with a thickness of 50 mm. When it completely hardens, a dense layer is created.

The coating does not interfere with air circulation and at the same time protects the surface from water penetration. Heat insulating paint can be used to finish metal and wooden surfaces. In addition, it is good because it is very easy to apply on the walls.

Do-it-yourself garage insulation

For reliable thermal insulation of the garage, it is necessary to protect not only the walls, you will also need to insulate the floor, entrance gate, floor surface and ceiling. The range of materials suitable for this is huge, and you can choose what you need for a particular building. Most often they stop on mineral wool or polystyrene, and the floor is mainly insulated with expanded clay.

It makes sense to combine different heat insulators, since building structures are erected from different materials.

Floor insulation

The floor in the garage is most often made concrete, so it is advisable to insulate it during pouring. If you purchased a ready-made garage, then the floor will be difficult to protect from the cold, since during work its surface will become much higher. An alternative is to remove part of the soil and lower the floor level.

Work sequence:

- The soil is leveled and well tamped,

- A layer of sand is poured in 10-20 cm, and it is also carefully compacted,

- A concrete screed is made on the finished sand cushion, after which they are waiting for the mortar to set,

- Expanded clay is used as a heat insulator,

- The insulation is mixed with cement and a concrete solution is prepared on this basis,

- Pour the floor with the resulting mixture and wait for the surface to harden,

- At the end of the work, they make the finish screed.

Ready floor should not be used for about a month - this period is necessary for high-quality hardening of concrete.

The need for insulation and ventilation

Parking and storage of vehicles in the garage should take place under certain conditions, which will be conducive to maintaining the performance properties and durability of the vehicle.

Basic requirements for maintaining a microclimate in the garage:

- in the cold season, the temperature should be within +5 degrees Celsius, which is the optimal value for storing a car,

- the room should be equipped with a ventilation system that provides an air flow of about 180 cubic meters. m per hour per unit of vehicle.

There is another typical mistake in the production of insulation. It is connected with the fact that all places where the influx of external air into the garage is possible are eliminated, and ventilation openings are not excluded. Lack of ventilation can lead to extremely negative consequences for human health, even death.

In addition, one should not forget about such a phenomenon as thermal inertia, it affects the rate of change of body temperature over time. Therefore, thermal insulation should be arranged so that its thermal inertia increases inward, and thermal conductivity, on the contrary, decreases.

The physical essence of heat transfer

When warming the garage, it is important to make the right choice of insulation materials. Without understanding the nature of the ongoing heat transfer processes, this is difficult to do. The following physical processes are interesting for the conditions of a garage:

- convective heat transfer, in which thermal energy is transferred from the body with a higher temperature to less heated,

- conductive heat transfer, which occurs by transferring heat from warmer parts of the body to areas with a lower temperature,

- thermal radiation, which is electromagnetic, due to the internal energy of the body.

Thus, the most effective will be such a heater, which prevents the flow of convective and conductive processes and has the ability to reflect thermal radiation.

Insulation of garage walls outside

The insulation of the garage outside is recommended using foam. This material has the required thermal insulation properties at an affordable cost. At the same time, it is necessary to provide, in places where the effect of high temperature is possible during the operation of equipment or heating devices, the replacement of plastic with non-combustible mineral wool plates.

Before installing the foam plates, it is necessary to carry out preparatory work. First of all, thorough cleaning of the walls and removal of surface defects should be carried out. After which it is advisable to prime it for better adhesion to the insulation material.

Polyfoam can be attached to the garage wall using the spot method of applying the mortar, followed by tight pressing to the plane. The plate method is simpler, in which the solution is evenly applied with a spatula.

Laying slabs must occur from bottom to top in a checkerboard pattern. The first row is laid with the use of an initial bracket mounted on the wall. In order to secure the plates, they are additionally attached using plastic dowels.

Due to the low strength of the insulation material, there is a need for its lining. To do this, plastering is used with fiberglass mesh reinforcement and the further application of a layer of decorative plaster and paint. Often used for this siding or materials of a similar purpose.

Insulation of the walls of the garage from the inside

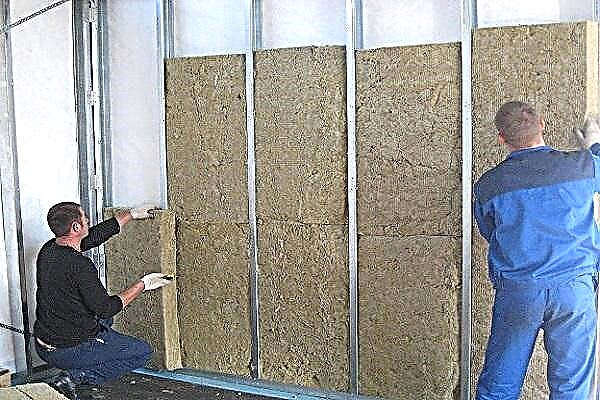

Internal insulation of the garage is rare. If such a need arose, the procedure will be as follows. On the prepared surface, a prefabricated false partition is fastened, in the frame of which a heater is inserted.

In addition to drywall, asbestos fiber can be used. This material has a high level of fire resistance, but it has significant fragility. This necessitates the creation of a frame with a smaller step.

Wadded insulation is widely used, which is explained by the greater simplicity of the work compared to polystyrene. For installation of cotton wool special hooks are used. A prerequisite for this is the need to create a vapor barrier using a membrane.

Application of modern liquid heaters for thermal insulation of metal structures of garages allows to achieve the desired effect. It is possible to reduce the cost of money and time when warming an iron garage by installing foam boards with glue. The main condition for reliable material fastening is a thorough surface preparation. Joints of plates must be blown out using construction foam.

Garage door insulation

Heat losses through the garage door can be reduced even at the design stage. If you provide a gate in one of the wings, then there is no need to open them completely. Also an effective method of preserving heat is the creation of a curtain of plastic or fabric.

For insulation of garage doors, the most optimal heat insulator is foam. To this end, a crate is created on their inner side, into which foam plates are laid with the subsequent sealing of the joints between them.

During the operation of insulated gates, condensation forms at the points of contact between the metal and the heat insulator. Therefore, metal surfaces must have a protective layer of anticorrosive material and additional waterproofing. After that, the frame is mounted for attaching the sheathing with wooden battens or OSB.

Garage roof insulation

In the event that the garage is a freestanding structure, there is a need for insulation of its roof. To fasten the thermal insulation, a technique is applied that corresponds to the material from which the overlap is made. If it has a wooden base, then the foam can be fixed with dowels or nails, and subsequently veneered with a suitable facing material.

For concrete floors, it is necessary to construct a frame reinforced with metal corners and self-tapping screws. The foam is laid on the frame and pre-fixed with adhesive tape. When fixing the sheathing sheet material, the insulation is tightly pressed to the ceiling.

If fiber-based insulation is used, measures for waterproofing are necessary. A waterproofing layer is placed on one side of the roof, and a vapor barrier is arranged on the side of the garage.

Antiseptic treatment is carried out to protect against the effects of biological factors, and to improve the appearance - decorative surface lining with various compositions or paints.

Ceiling insulation

According to the laws of physics, warm air rises, so the ceiling must be insulated necessarily. To do this, it is best to use polystyrene.

The sequence of work is as follows:

- The choice of mounting method depends on the material of the floor. On the wooden ceiling, you can mount the foam with simple nails.On a concrete floor, you must first make a frame in which heat-insulating material is placed. In this case, the foam can be fixed with tape, and then covered with plywood or decorative cladding,

- All gaps and crevices are covered with foam,

- The plywood surface on the ceiling is impregnated with antiseptics, cleaned well and then painted.

Wall insulation

To warm the walls of metal, you must first align the bent sections. As a heat insulator, it is desirable to use a heat insulating paint, polyurethane foam or foam. For garages built of brick or cinder block, mineral wool is mainly used.

The sequence of work with mineral wool:

- The walls are cleaned, the frame is prepared,

- Heat-insulating material is placed in the finished frame, fixing it with special hooks,

- The insulation is covered with a vapor barrier material,

- Any decoration will fit, mount it after laying the vapor barrier layer.

- The surface is leveled and prepared.

- Fix the foam with glue, uniformly pressing across the entire area,

- Sheets must be placed end-to-end, covering all gaps with foam,

- After curing the foam, all protruding surplus is removed,

- The walls are puttied and covered with suitable paint.

Attention! Do not forget that the foam begins to release toxic compounds into the air during a fire. It is necessary to comply with safety rules and it is imperative to have a workable fire extinguisher ready in the garage.

Gate insulation

Metal door leafs are conveniently protected from the cold with foam. It’s good to make a thermal curtain, for this a thick film or dense fabric is hung in front of the gate.

The sequence of work on insulation of the gate is as follows:

- First of all, a crate is made at the gate, after which sheets of insulation are fixed in it using dowels or glue,

- Any gaps, seams and joints between the sheets are covered with foam to eliminate the cold bridges,

- The foam laid in the crate is smoothened with putty, coated with paint or protected with decorative sheathing sheets,

- After that, polyethylene strips with a width of 20-30 cm are hung in front of the gates as a heat curtain.

Each garage owner decides for himself how convenient it is to insulate the garage. It is important to choose a reliable way of protection from the cold. It is best to seek the advice of professionals who will help you choose the right materials so that the insulation of the garage costs you inexpensively and the insulation is durable and effective.