Repair in an apartment or in a private household usually requires the replacement of interior doors. This can be dictated by the concept of a new interior design, and the need to improve the functionality of door structures, and the desire to save free space for furniture. One way or another, the choice of interior doors can be difficult. To make the right decision, you need at least minimal knowledge about what kind of interior doors are, which ones are better and why. Let's try to understand these issues.

Types of interior doors

One of the key differences of any doors is their design. Structurally, interior doors are divided into the following varieties:

- Frame doors sellers are often also called shield. As the name implies, these doors consist of a frame and a web sewn onto it. This type of interior doors is widespread in the economy class, but that is why such designs often have quality problems. Here are a few household tricks that will help you choose interior doors for quality:

- Go through the hall from budget to expensive models and open them. The deaf silent clicks of locks speak about proper quality of accessories. Conversely, a loud and loud mechanism of operation of the locking device serves as a signal - purchases of such products should be avoided.

- The rigidity of the frame can be checked by carefully placing your foot in the opening and trying to close the top of the door. A weak frame is immediately visible by the bending of the panel.

- Sometimes the seller is cunning and equips budget doors with expensive locks in the show room. Ask him about the correspondence of the level of the lock and the door by price class.

The frame of the panel doors can be made of solid timber, veneered veneer lumber (LVL) or glued profiled beam (Glulam). The last two types of timber are often of better quality and less afraid of moisture. Glulam timber consists of small fragments of solid wood glued together under a press. LVL beam represents a multilayer veneer from coniferous breeds. The modern gluing method and the correct orientation of the direction of the wood fibers guarantee high strength and resistance of glued types of timber to deformation.

Attached to the frame in the shield door outdoor panel more often a fiberboard MDF (Medium Density Fiberboard)veneered with laminate, polypropylene or PVC film. It can be smooth or have a raised (milled) surface. Additionally, in the cavity between the frame and two planes of the outer panels of high-quality doors are installed stiffening rib. It is located here sound insulating filler.

The most budget options are smooth hollow doors with inexpensive MDF panels. They can be found in almost every hardware store or in the market next to huge inscriptions promising low prices and impressive discounts. But the functionality and durability of such a product is very doubtful. Only with the delivery of houses for rent or the sale of finished housing such doors justify themselves. Therefore, they are successfully used by construction companies as temporary structures. Hollow doors have neither protection nor aesthetics, and, as a rule, they warp and dry out, warp and stop closing over time. At the same time, a door of this design, made qualitatively by all standards and with taste, looks presentable and lasts a long time without complaints.

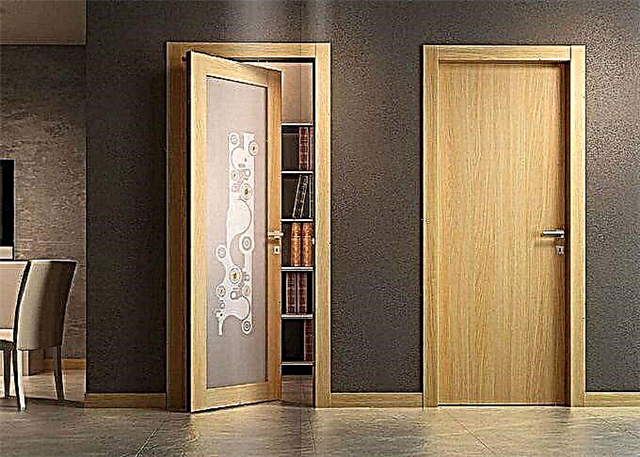

- Paneled - variety collapsible doors. They share popularity with switchboards, but fundamentally differ both constructively and externally. Filenka - This is a decorative element made of various materials (MDF, plywood, solid wood, glass), which is inserted inside the trim (perimeter, frame) of the door leaf. It should be noted that the panel is always thinner than the main frame and forms a natural recess in the profile of the door. Depending on the design and constructive solution, 2 to 10 panels can be used in the door leaf, including from various materials (for example, MDF and frosted glass) and various geometric shapes.

To the question "Which interior doors are the best?" half of the experts will probably say - paneled. The advantages of these doors include:- Resistance to changes in temperature, humidity and other types of shrinkage.

- Presentable appearance.

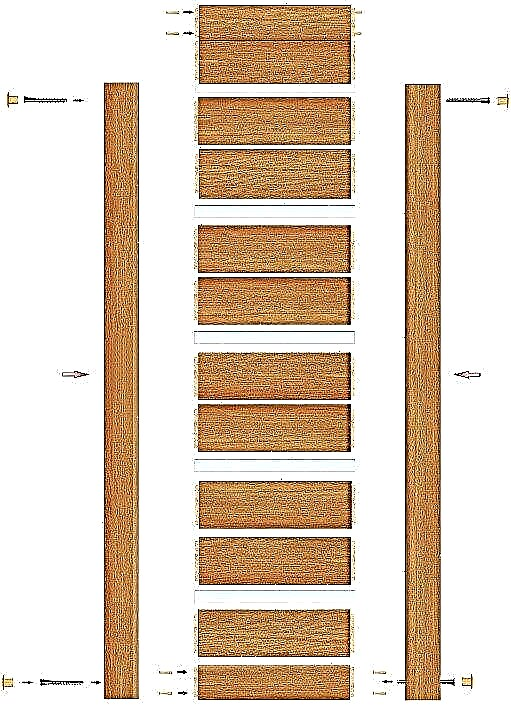

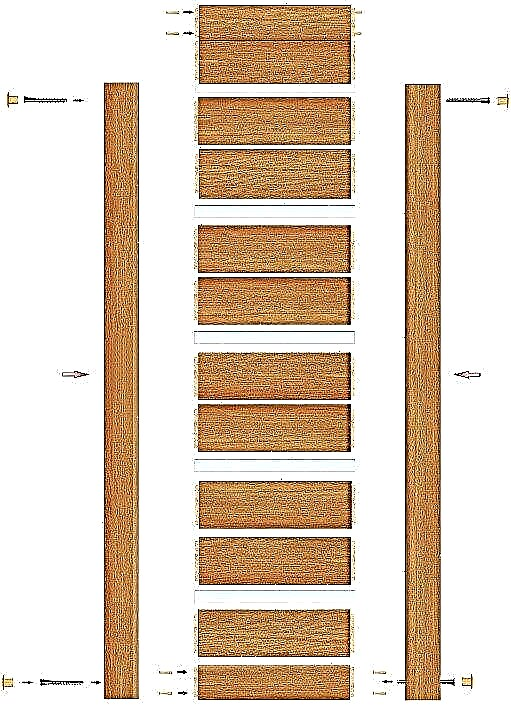

- Drawer doors as well as paneled, refer to collapsible structures. The highlight of the modern interior is precisely such doors. Purely technically, they are a variant of the panel, but they are made using a slightly different technology. The canvas in such doors form two vertical sidewalls (stand profiles), connected by transverse beams (drawbars) with the help of inserted cylindrical spikes (dowels) and coupling screws.

The horizontal elements of the canvas (we can say, panels) are inserted into each other and into the vertical sidewalls by means of longitudinal protrusions on the rib (dowels) and grooves. Horizontal elements give the construction additional rigidity. All parts are individually coated with protective decorative materials (PVC or PP film, enamel, laminate) before assembly, which means a higher quality coating - without edges and visible joints: after assembly, nothing will peel off and moisture will not get into the inner layers MDF. Visually collet doors increase the opening due to the powerful horizontal pattern. But the ability to make transparent inserts of any size helps to visually lighten the structure. Push-in doors can be bought in the range from the middle to the highest price segment. They are distinguished by an unusual appearance in combination with the solidity of the product.

The horizontal elements of the canvas (we can say, panels) are inserted into each other and into the vertical sidewalls by means of longitudinal protrusions on the rib (dowels) and grooves. Horizontal elements give the construction additional rigidity. All parts are individually coated with protective decorative materials (PVC or PP film, enamel, laminate) before assembly, which means a higher quality coating - without edges and visible joints: after assembly, nothing will peel off and moisture will not get into the inner layers MDF. Visually collet doors increase the opening due to the powerful horizontal pattern. But the ability to make transparent inserts of any size helps to visually lighten the structure. Push-in doors can be bought in the range from the middle to the highest price segment. They are distinguished by an unusual appearance in combination with the solidity of the product. - Combined doors are created using mixed technologies and combine panel board and collapsible structures. The appearance of such doors is a symbiosis of engineering solutions in an attempt to eliminate the shortcomings inherent in a particular design. Combined doors carry the advantages of each constructive solution: strength, rigidity, excellent sound insulation and aesthetic qualities. The abundance of various finishes can please the most discerning buyer. Often, sellers do not distinguish a mixed door design in a separate category, ranking it as the prevailing structural design. But if a similar door is manufactured according to existing standards, it will serve for a long time and without fail. Additionally, all doors of combined structures are most often filled with “honeycombs” from the inside. This is necessary to improve the soundproofing qualities and reduce the resonant effect during door operation. Voids in such doors are practically excluded.

Which interior doors are better to choose by material and type of construction

Various elements of door structures are made using both natural and synthetic materials.

Based on the indicators of strength, wear resistance and unpretentiousness, then in the first place are artificial materials. Quality interior doors from solid wood, especially valuable breeds, is expensive or very expensive. They will emphasize your status and environmental friendliness of the interior, but will be rather capricious in operation and maintenance.

Therefore, there is a compromise option: derivatives of 100% wood, very similar in structure, but more accessible to the buyer materials. This category may include glued brufrom, natural and "Online" (restored) spon.

Ecointerline interval distinguishes polymer base with the addition of natural wood fibers and special dyes. This technique allows you to achieve the most natural texture of the material. In addition, the eco-veneer is pleasant to the touch.

Eurointerline - a new word in door production. This is a completely artificial material, which is a multilayer polymer film that most accurately simulates a natural tree of any valuable species. Eurospan does not burn, does not release toxic substances into the air, does not decay, does not fade in sunlight, does not cause allergic reactions.

Stand alone glass doors with various levels of glass finish. The existing myth of the fragility of such doors is viable only for cheap models of artisanal manufacturers. In practice, glass doors have sufficient strength and original appearance. Often they use unbreakable triplex or tempered glass. Glass doors should be considered in the middle and highest price range.

Depending on your needs and features of the layout of the living area, you can choose doors with different opening principles. Many do not think about it and simply adhere to already established traditions. But perhaps a different way to open the door will save you from inconvenience or provide additional space in the house. According to the type of opening, interior doors are divided into:

- Swing - The most common and conservative type of interior doors. If there is a wide swing opening on a permanent basis, you can only make part of the door - this will save space when opening. When installing new furniture, you can always open the second part.

- Sliding - the design of such doors came from Japan. According to the principle of the device, they can be parallel-sliding and sliding-folding. The first versions are coupe, cassette, radius and cascading interior doors. The second ones are “books” and “accordions”. According to the principle of installation, sliding doors can be with upper, lower or combined guides, in-door or with the installation of an overlap wall. The disadvantage of such doors can be called low sound insulation and, as a rule, the short service life of the sliding mechanism is within 5 years.

- Swaying. This door structure is not common, but not without advantages. The swinging door is able to open in both directions, has great inertia and requires care when opening. It is recommended for installation in through passage openings.

- Rotary, or rotary-sliding, - door leaf mounting systems combining the pendulum, sliding and swing principles of operation. A closed roto door looks the same as a regular swing door. Features of this design are manifested only when opening: the door swings open and at the same time in the center of the canvas moves toward the opening. In this case, bilateral opening is possible - to the right or to the left. In open form, half of the canvas remains in one room, the second half - in another. Such opening systems are very expensive, which is due not only to the complexity of the mounting mechanism, but also to the fashion trend.

What interior doors are better to choose for the house

This question cannot be answered in monosyllables, if only for the reason that attention should be paid to several criteria at once. Ultimately, the quality of the door will depend on its design, material of manufacture and method of decoration. We’ll talk about these selection criteria in detail. Only after that you can carefully and consciously make a choice in favor of this or that type of interior door.It would be wrong to give universal advice at the very beginning of the article.

Panel interior doors

This type of door is one of the most common mainly due to affordable prices. But this does not mean that such doors are not high quality. If they are made by a well-known manufacturer in compliance with the required technology, then such doors may well be the best choice, if you do not claim, of course, to exclusive options in this matter.

Structurally, the panel door consists of a frame made of a wooden bar. Most often, pine is used for this, as the most accessible and well-preserving material. Due to the use of this frame, such a door is often called a frame door.

The internal cavity of the frame is filled with soundproofing material from a mineral plate or synthetic material, or honeycomb is placed.

Outside, the door frame is sheathed with MDF sheets about 5 mm thick.

But these sheets are already being finished, so to speak. To do this, they are decorated with natural veneer or covered with a laminate, polyvinyl chloride (PVC) or polypropylene (PP) film.

- Panel doors have the following advantages:

- in most cases they have a low price,

- such doors are lightweight,

- panel doors are strong enough

- There is a wide selection of finishes.

True, there are exceptions to the manufacturing options for this type of door. For example, in a high-quality panel door, an oak frame and a natural veneer finish can be used. But in this case it’s not worth talking about affordability.

The disadvantage of this type of interior doors can be considered not very high durability. But this is only if lamination with melamine paper is used for decoration.

Milled interior doors

The design of such doors, in principle, does not differ from panel doors. There are also a frame, a filler, MDF panels. But in this case, the outer part of the door does not have a smooth surface, but a figured relief that gives the door a more aesthetic and attractive appearance.

Milling the door required the installation of outer MDF sheets of greater thickness or the use of additional bars that strengthen the structure. This entailed, of course, some appreciation of this type of door. Moreover, with such a relief surface, lamination with melamine paper cannot be used anymore. So you need to use PVC or PP film, which improves the quality of such a door. More affordable in this case is a PVC film coating.

Panel doors

This type of interior door has significant differences from the previous ones. Although as the basis of its design it has the same frame, made, as a rule, of pine. Plates of various configurations made of natural wood or MDF panels are installed inside the frame. They are called panels.

Such panels can also be made from valuable species of wood.

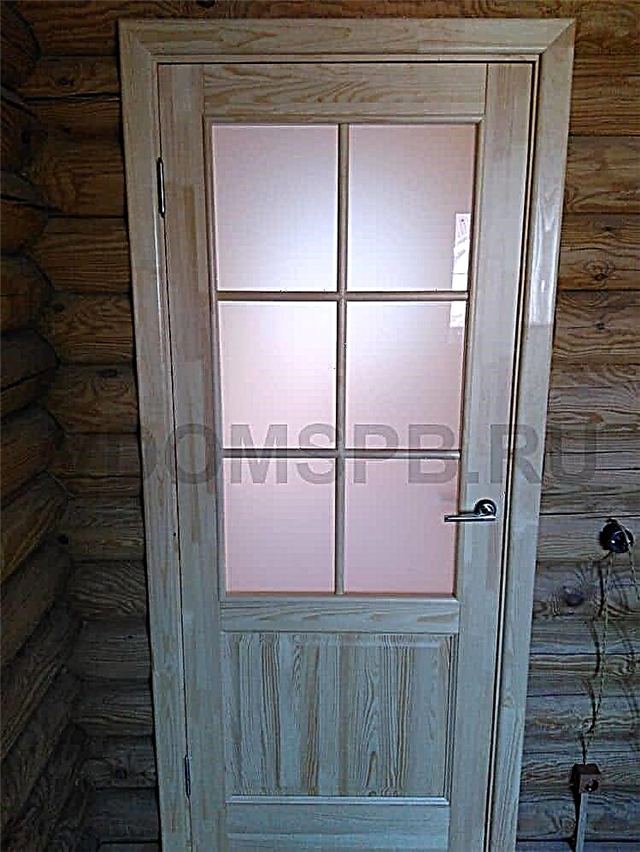

Doors of this type, as well as milled ones, can be made both with glazing and without it.

Regardless of the material of the panels, such doors look more elegant.

The advantages of panel doors include their strength, solid appearance and good sound insulation.

The downside is only a higher price.

Drawbars or prefabricated doors

The basis of the design of these doors is also the frame, but otherwise there are significant differences from other types of doors.

The interior space of the frame of the drawer doors is filled with horizontally placed planks, which are called draw frames. Between them can be placed inserts of glass or other material to give the door a greater external attractiveness.

The design of such a door is strong enough due to the fact that during assembly the drawers are not simply inserted into the guides of the frame racks, but are attached to them with dowels and coupling screws.

With the seeming simplicity of the design, such doors look quite solidly and effectively.

Molding doors

It remains to consider the last type of interior doors, which is completely different from all the previous ones.

The classic design of a molded door consists of two vertical boards made of MDF, and a strong three-layer glass located between them.

With the seemingly unreliable design, such a door is quite durable.

But its main advantage is a modern, stylish appearance.

Such doors will be appropriate primarily in interiors made in the style of hi-tech or minimalism.

Materials for the manufacture of interior doors

Interior doors are currently made both from natural materials and from artificial. Both have their strengths and weaknesses. Therefore, when deciding on the choice of a door, you need to take into account the conditions of its operation and your financial capabilities. That is, we will try to find the best option.

Solid wood interior doors

With all the variety of artificial materials, solid wood doors still occupy higher positions in terms of quality and aesthetic perception.

Not to mention the fact that they are environmentally friendly.

But at the same time, such doors have weaknesses:

- Solid wood doors are sensitive to changes in temperature and humidity. This must be taken into account when it comes to the bathroom. In this case, the door from the array can be used, but better in painted form.

- Such doors are subject to drying out for the above reason, especially if they are made of insufficiently dried wood. This circumstance must be taken into account and not buy this type of door in the "garage" workshops.

- Doors made of natural wood are not widely sold, or at least there is no good choice. Therefore, such doors are often made to order.

- Such doors have a fairly high price. This is, of course, if valuable species of wood are used, such as oak, walnut, and beech.

True, there is a compromise solution. It consists in the fact that interior doors are made, including, from less expensive types of wood. First of all, it is pine, which at a low price has very good properties. It is strong enough, it does not twist when dried, its weight is much lower than that of oak and beech.

Pine doors can be left with a natural texture, covered only with protective varnish, and can be treated with high-quality stains to give a more noble look.

Separately, it must be said that natural wood can be used both completely for the door, and for its frame, as well as as an internal filler. This most often happens in practice.

Interior doors made of artificial materials

The most commonly used artificial materials are particleboard (MDF) and MDF. The name MDF means finely divided fraction and comes from the English abbreviation MDF.

Of these two materials, MDF is undeniably the best. These plates are strong enough, are well processed, are milled to give a figured relief, and are environmentally friendly at room temperature.

Chipboard boards, probably, can already be considered material of the last century. In terms of consumer properties, it is inferior to MDF in almost all respects.

For internal filling of doors, honeycomb cardboard is also used. This is the most budget option and it makes sense to choose it only if financial resources are limited.

Interior door coating: which is better in quality?

The covering of the interior door should be taken seriously for the reason that its performance will be largely determined by the chosen type of coating. This is especially true when it comes to doors for the kitchen or bathroom, where the influence of high humidity, greasy fumes, temperature changes is significant. Therefore, it makes sense to consider the main types of coatings for interior doors, their advantages and disadvantages.

Laminated coating

This type of coating has long been known. It is the cheapest, therefore, often associated with low quality. This is partly true, but something needs to be clarified.

There are two ways to laminate doors.

The first consists in covering with melamine paper, on which a drawing imitating a wood texture is preliminarily applied. To give this paper more moisture resistance and wear resistance, it is impregnated with resins and coated with a thin layer of protective varnish.

This coating option is the most budgetary and, unfortunately, does not guarantee the door sufficient durability.

Second The method of lamination is more modern and allows to provide higher consumer qualities of interior doors.

It consists in the use of laminate, which is a double layer of paper, impregnated with a special protective composition and glued under high pressure to a non-woven substrate.

Such a door also turns out to be quite cheap, but already more durable.

Therefore, it can already be considered as one of the suitable options with a limited budget.

PVC door coating

PVC coating has been used for quite some time. At first, the decorative properties of such a coating were not up to the mark for the reason that it was not possible to qualitatively imitate the texture of wood of different species.

This issue is currently resolved. Doors with PVC coating look very decent. It is possible not only to imitate the texture of the wood, but also to create the effect of a painted surface, which is fashionable for some styles of interior decoration, such as country, Provence or neoclassic.

In addition, this coating is quite resistant to both mechanical damage and the effects of chemical detergents. Using a PVC film, it is possible to cover not only smooth surfaces of panel doors, but also various embossed surfaces.

PP door coating

A coating of a polypropylene film is advertised more than PVC, although there is practically no fundamental difference in consumer properties. Therefore, it is probably not worth describing in detail the advantages of a polypropylene coating. This coating is as practical as PVC, only more modern.

Present on the market under various names, such as nanotex, cortex, acrylate, simplex. In fact, it is one and the same polymer film.

The quality of such doors is quite acceptable. True, the price is slightly higher than with PVC coating.

Veneer coating

This type of coating is no longer intended for budget options for interior doors. But in this case, there may also be options. The fact is that there is a coating of both natural veneer and artificial. Now we will briefly consider them.

Natural veneer coating

This type of coating is one of the most expensive. Interior doors with such a coating are comparable in price to doors made of solid wood.

The reason is a rather high price by the fact that valuable species of wood are used to produce this type of veneer. First of all, it is oak, ash and mahogany.

Natural veneer is a thin section of wood with a thickness of not more than 2 mm, glued to the door frame by hot pressing and coated with a protective varnish.

Doors with such a coating look, of course, quite noble.

Veneer Finishing Online

If you like covering from natural veneer, but your plans do not include the use of a significant amount to purchase such a door, you can choose the option of covering from natural, but cheaper veneer. In this case, wood of less valuable species is used. Such as maple, aspen, poplar.

Since these tree species do not have a beautiful texture, veneers made from them are tinted in different shades.

Coating from such veneers also looks good, but the minus is that these tree species have a lower density, unlike oak or ash. Therefore, to increase the strength of such a veneer, it is covered with a sufficiently thick layer of varnish.

The ecointerline interval is a modern and sufficiently demanded coating for interior doors. Its essence is that the ground wood waste is impregnated with a polymer material and rolled under a press with a certain relief pattern and painted in the desired color. The result is a coating to the touch and in appearance resembling a natural veneer.

Consumer properties of such a coating are quite good, but there is one drawback, or rather a limitation. The eco-veneer does not stretch, so it can not be used, say, on milled doors. Such veneers can only be wrapped around individual door elements. Therefore, king doors are an excellent option for using such veneers.

How to choose the color of interior doors to the apartment

Interior doors not only perform a specific function. They are an important and very noticeable element of the interior of the room. Therefore, they should organically fit into this interior, and not just be a beautiful spot that has nothing to do with the general concept of the interior.

This means that the doors should be selected both in style and in color.

In design, there is one of the known rules when various elements are selected either by contrast with each other, or by the principle of harmony.

Both options have a right to exist. The only thing that should be noted is that not everyone can competently and successfully design an interior according to the principle of contrasts. This is most often done by professionals. But if you are confident in your sense of taste, then this is welcome. If not, then it will be safer to choose colors that are close to furniture or floor. You can focus on the walls, but then it will need to be taken into account each time you paste wallpaper or paint the walls.

You can hear the opinion of professionals and see specific examples of door color selection in this video.

Which bathroom doors are better to choose

In this case, the door will have to somehow struggle with periodically increasing humidity and temperature changes.

If you want the door to be installed in the bathroom from solid wood, then such a door should be well protected. The door covered with high-quality varnish, which allows you to save the wood pattern, probably looks more beautiful.

But more reliable in this case will be enamel coating, that is, a painted door.

If the second option does not suit you, then it is quite possible to use the interior door with PVC or PP coating. Such doors can tolerate high humidity, unless of course they are made by a professional manufacturer in compliance with modern technologies and do not have delamination on the edges.

But in any case, the bathroom should have good exhaust ventilation.

Rating of interior doors in quality 2019

We examined with you questions about which materials are best for the manufacture of interior doors, which coatings are more reliable. This is all really important, but still does not guarantee an excellent end result.

A good end result is guaranteed only by a good manufacturer, because it is difficult to make a high-quality door using modern technology even in good materials in artisanal conditions. Such as, for example, milling with PVC or PP coating.

Therefore, it makes sense to focus on well-known, well-established manufacturers when choosing a door.

These can be called about two dozen manufacturers specializing in the production of various types of interior doors.

Let's get to know them in more detail.

Laminated Door Manufacturers

Belwooddors company is located in Belarus, and has already earned a good reputation in the market of inexpensive interior doors. They use modern technology of lamination, which allows the manufacture of doors with high wear resistance at affordable prices. For this reason, such doors have already begun to be faked. So be careful.

Why such an ambitious name for the company is not clear, because it produces modest products in the form of laminated doors, and not of the highest quality. For example, the wear resistance of these doors is slightly lower than that of Belwooddors.

The strengths of this company are the best closing mechanisms and affordable price.

Verda (software Odintsovo)

This manufacturer is a leader in sales, but not in quality. Positive and negative reviews are divided approximately in half. On the one hand, an affordable price, good appearance and a large selection of models bribes. On the other hand, not very high practicality, durability and

PVC Door Manufacturers

This company has several factories with the latest imported equipment in the Russian Federation. A distinctive feature is strict control at all stages of production and, as a result, very good quality of products. More than sixty color schemes for interior doors are offered.

Good quality handles and hinges included.

Soundproofing doors is also not satisfactory.

But it should be noted that pricing is focused on middle-class buyers.

A distinctive feature of this manufacturer is the original design of products that they develop themselves, and do not copy from competitors. Production is located in Moscow and the Moscow region.

In pricing policy, the company focuses on the budget and partly on the middle segment.

The interior doors manufactured by Matador are quite durable and do not require special care. This quality and reasonable price explains the popularity of such doors in the segment with PVC coating.

There is an opinion that the content of chloride in the protective coating limits the use of these products in such residential premises as bedrooms and children's rooms. But it is more often used by competitors and is not entirely justified. After all, chloride is released at temperatures above 100ºС, and at room temperature it is safe.

This door factory is one of the most famous manufacturers in Russia.

The secret of success, most likely, lies in a good ratio of price and quality, as well as a large selection of models and colors.

A wholesale warehouse of finished products is located in Moscow, but in general such doors can be purchased in many cities of the Russian Federation.

The doors of this company differ markedly from similar products from other manufacturers. They are the most moisture resistant in their segment, have increased heat and sound insulation. The wear resistance of such doors is also very good. These doors come complete with a door frame.

Eco-veneered door leaders

Status (LLC "PC Novgorod Doors")

This manufacturer relies primarily on product quality. This is confirmed by a five-year guarantee for each door and a quality certificate.Door delivery is carried out in cardboard boxes, which eliminates damage during transportation.

The price of such doors cannot be called low, but due to the high quality there is a demand for these products.

A feature of this manufacturer is that the production is based on imported equipment using Italian technology. Quality control is ensured at every stage of production. Materials are used only in high quality. All this makes it possible to produce products of the European level.

No wonder this company is one of the leaders in terms of sales in its segment.

TriaDors (Vladimir region)

A distinctive feature of this manufacturer can be considered a very wide range of interior doors, environmentally friendly materials used in production and a flexible pricing policy. You can choose a model from a budget to a premium class. The basic package includes everything you need, that is, a door leaf, a box, platbands and accessories.

Profile Porte (Moscow Oblast)

This enterprise is a joint Russian-Italian. Perhaps this explains the high quality products. As a rule, foreigners require strict adherence to technology.

It is noteworthy that this company produces interior doors of very decent quality at a price quite reasonable for this segment.

Doors from Profile Porte are quite durable and have good moisture resistance and sound insulation.

Leading veneered door manufacturers

This company has been mass-producing interior doors since 2004. During this time, sufficient experience has been gained in the manufacture of not only standard models, but also in the development of our own collections that meet modern requirements, both in design and in consumer qualities. Veneered doors are in the highest demand.

Onyx factory has been producing interior doors since 1997. Therefore, you cannot call her a newcomer to the veneered door market. The production uses German and Italian equipment, which allows to produce products that meet European standards.

This manufacturer has a large selection of colors for veneered doors and an affordable price.

Mario Rioli (Tula Region)

This company compares favorably with the fact that it independently provides a full production cycle of high-quality doors, starting with self-drying of raw materials and finishing with finishing. This allows for product quality control at all stages.

Doors of this manufacturer are sold with already installed hinges and a lock, which allows you to perform installation without resorting to the services of specialists.

This factory has been operating since 2006 and has earned a good reputation in the production of veneered doors.

Among the positive factors, a large selection of door models and more than thirty types of veneers are noted. In addition, the advantage is the use of high-quality Italian varnish in the protective coating, which ensures good appearance, moisture resistance and durability of the doors.

Leaders in the production of solid wood doors

Blum Industry (Krasnodar)

At this manufacturer, Remarque belongs to the premium collection. For the production of these doors, an array of beech with a moisture content of not more than 8% is used, which allows us to produce high-quality products.

These doors are made in a luxurious classic style or noble Art Nouveau style. Cloths can be both deaf, and with a glazing. They can be tinted in shades of oak or walnut or painted in pastel colors.

The quality of such doors is certainly good, but the price is appropriate.

Unlike the previous manufacturer, which manufactures only premium-class doors from solid beech, the Oka factory offers customers solid oak doors, as well as at more affordable prices, solid pine and alder doors.

Of the color solutions, antique walnut, ivory, white enamel, mahogany, wenge and others are offered.

How to choose an interior door: professional advice

In this rather lengthy article, we examined a lot of useful information regarding the choice of interior doors.Let’s now summarize in order to have a clearer picture of how to choose interior doors to an apartment for quality and a reasonable price.

How long will your chosen door last?

The answer to this question depends on several important factors:

- door structure

- door leaf material

- type of finish and protective coating,

- door manufacturer.

Let's briefly run through the main types of interior doors once again, consider their advantages and talk about how to distinguish a good door from a low-quality fake.

Coated Doors

This category includes interior doors of the budget segment. It is these doors that are sold and bought in greatest quantity. According to the type of coating, these doors are divided into laminated, with PVC coating, PP coating and eco-veneer coating.

This type of door is the most affordable. But, as they say, miracles do not happen, therefore such doors do not differ in special durability. On average, such doors will last about five years without losing their appearance. And the soundproofing of such doors is not very good.

If you are limited in means, do not set the door for the rest of your life, or for some reason change it in a rented apartment, then this will be the best option.

By the way, at the beginning of the article it was said that at present there is a more advanced version of lamination using laminate rather than melamine paper. Therefore, from well-known manufacturers you can purchase a better quality laminated door.

What to look for when choosing a laminated door?

PVC coated doors

This type of door has a stronger PVC protective film. This significantly enhances the performance of such doors. They have good moisture resistance, are more resistant to mechanical damage and can withstand up to ten years.

In addition, PVC film allows you to cover curly embossed door surfaces, which makes them more attractive.

At the same time, the price of such doors is quite affordable.

PP coated doors

The polypropylene coating is not much different in characteristics from the PVC coating, but it is considered more modern and safer from an environmental point of view, since it does not contain chloride. Therefore, such doors are slightly more expensive than PVC coated doors.

How to distinguish a laminated door from a door with PVC or PP coating?

Eco-veneered doors

Eco-veneer is one of the best and most modern coatings for interior doors. It is made from natural resins and wood fibers, therefore it is environmentally friendly.

When rolling in the press, the material is given a relief pattern corresponding to the texture of a tree of different species. Thanks to this production technology, it is very similar to natural wood.

The only limitation is that the eco-veneer does not stretch like a PVC film. Therefore, they will not be able to cover the doors with a raised surface. Most eco-veneers are used in the manufacture of plinth doors. But they also look very good and modern and have high strength.

The cost of such doors is slightly higher than with PVC or PP coating. Durability is about ten years.

Veneered doors

This type of door can already be attributed to the premium class. They really look very worthy in the interior, and their consumer qualities are also worthy. A well-made veneered door lasts up to twenty years.

For the manufacture of such doors, veneers with a thickness of 0.5 to 2 mm are used. It is not glued on a door frame made, for example, of pine, but on a substrate of MDF board. This is done for the reason that the geometric dimensions of wood change with temperature and humidity. And the dimensions of the MDF board remain almost unchanged. This prevents veneer cracking.

After that, the outer surface is carefully sanded, covered with several layers of varnish. In general, the technology is quite complex and expensive. Therefore, the prices of veneered doors are quite high.

But there are cheaper options. To do this, you need to use veneer not from valuable wood species, but from cheaper ones, such as aspen, maple, poplar. This veneer is called Fine-line. Doors with such veneers are also quite in demand.

How to determine which veneer is used?

Solid wood doors

Such doors are made entirely of natural wood. Therefore, this is the most expensive category of doors. They are good in appearance, environmentally friendly and quite durable. But this is only subject to full compliance with manufacturing technology. The fact is that wood is very sensitive, in comparison with artificial materials, to changes in temperature and humidity. This leads to warping and cracking.

In order for the doors from the array to be durable, the following conditions must be observed:

They must be made of carefully dried wood without defects, otherwise the door will not dry out.

The design is preferred paneled or collet, which does not cause internal stresses of wood and cracking.

The outer coating must be of high quality. Only in this case, a solid appearance and good durability will be provided. One of the best currently considered Italian varnishes.

Solid wood doors

These species of the most common include oak, beech and ash. High-quality doors made of such material are a classic of the genre, the spirit of aristocracy, a symbol of strength, reliability and durability.

The cost of such doors starts from 25 tr. per standard unit and can be over 100 tr for manual work.

Solid pine doors

Of course, there are options for interior doors from an array with a more affordable price. For example, pine doors.

Such doors retain some of the advantages of more expensive hardwood doors. This is a pleasant appearance, high environmental friendliness, good sound and thermal insulation properties.

But there are, of course, weaknesses. First of all, the pine is much softer than oak and beech. For this reason, a solid pine door easily acquires deep scratches and dents during operation. Yes, and in rooms with high humidity, such doors should also not be used, even with varnish impregnation. You can use it more precisely, but it will not be the best option.

A few words about how to distinguish a quality door from an array of other proposed options.

Painted doors

You need to immediately clarify that we are not talking about doors painted with enamel from the nearest store. Painted doors are not something second-rate. The technology of painting high-quality doors is no simpler than varnishing doors from solid wood.

Staining is carried out in several layers with various compositions. Multiple grinding is used to create a glossy surface. Such a door looks no worse than a solid wood door. Of course, you need to use them in a properly selected interior. For example, in the interior in the neoclassical style.

What possible defects should I look for?

You may find it helpful to listen to the professional's advice on choosing interior doors in this video.

By the way, if you are interested in the topic of the right choice of linoleum or curtains for the living room, then you can get acquainted with very interesting information on these issues here and here .

And the last advice on choosing doors that I would like to give you.

Doors, like any other elements of the interior, must match each other, both in style and quality, and therefore price. Of course, you can buy your favorite oak door for fifty thousand rubles and install it in a modestly furnished room. But does that make sense?

This chic door will stand alone in the interior, further emphasizing the indecent modesty of everything else that surrounds it.

It is more reasonable to choose all elements of an interior in one style and in one price category.

In this article I tried to give you useful information and some tips on how to choose interior doors to an apartment for quality and a reasonable price.

I hope that now it will be much easier for you to solve this problem.

Have a good choice!

Share "How to choose interior doors to an apartment for quality and price"

Eco-veneer, PVC or laminated - which is better?

Inexpensive doors remain one of the most popular among the population and among commercial structures.

To learn how to distinguish quality products from doors made “in the garage”, let's sort it out in order, examining the two main components of the price: the type of construction and the type of exterior decoration.

An inexpensive segment is represented by three types of structures: panel, milled and collet. Each of them has already been tested by time and has its own strengths and weaknesses.

Panel doors

Smooth panel doors are the cheapest available. Consist of a frame and two sheets of MDF. Rama is usually made from pine timber. The MDF cover gives the frame rigidity and stability of geometric dimensions. This is the simplest and therefore cheapest design. The life of such a product will depend on how the frame is made and how thick the MDF is. If the canvas is strong and monolithic, then its geometry will not change, gaps will not go away with time, and the canvas will not touch the box, therefore, the probability of peeling of the outer coating is less.

There are no special ways of checking the quality of the design in the store. Since cheap doors are bought quite often, you can find a lot of reviews on the products of this category on the Internet. Be sure to check them out. This will save you from buying a door that doesn’t last long.

The most inexpensive panel doors are made with a coating of melamine paper - these are the so-called laminated doors. This material has no relief and vaguely resembles a natural tree. In order to somehow improve the design, glass inserts of various shapes are made in a smooth canvas.

But there are absolutely smooth doors that look very stylish and no frills. The quality and beauty of the external coating are precisely the characteristics of such doors that attract buyers. Usually these are doors with veneers made of eco-veneer or other modern films. To diversify the minimalistic design a little, use jewelry in the form of metal moldings.

Another trend - the metal edge, will help get away from the main drawback of panel doors. Basically, the destruction of their outer coating begins with the edge.

Milled Doors

Smooth doors are not interesting to everyone, so manufacturers began to look for ways to make the product not only durable, but also outwardly attractive. For example, reliefs. The easiest way to get them is milling a smooth canvas. Depending on the milling depth, some improvement in the conventional frame structure will be required. There are two ways to achieve this:

- Using a thicker MDF,

- Bookmark under the MDF in the areas of milling additional bars.

In fact, milled doors are a variety of switchboards, as have the same monolithic base (frame and two sheets of MDF), only usually more durable and beautiful. As a cover for such doors, manufacturers use almost all modern film materials, but not on a paper basis, because the latter cannot be "pulled" onto a relief. In the low-cost segment, you should pay attention to the doors with PVC film cladding.

Drawbars or prefabricated canvases.

Drawer doors - This is another story altogether. The canvas consists of parts that are assembled on screeds and dowels.But their main advantage is not in this, but in the fact that each part is wrapped individually before the assembly, so the canvas does not have edges and visible joints. And this means that nothing will come off and moisture will not get into the inner layers of MDF.

All three designs of paintings have internal cavities. To improve performance, these cavities need to be filled with something. The most inexpensive doors use honeycomb cardboard. At first glance, a simple, cheap material, but with its advantages:

- It does not allow MDF sheets to bend as a result of pressing (cells with a mesh diameter of 45 mm have a strength of 500 g / cm2),

- It holds sound: if you evaluate sound insulation on a 5-point scale, you can put a solid triple of cardboard,

- Reduces the cost of goods

- Practically does not add weight to the canvas.

In canvases more expensive, insulators in the form of plates are used. The material is more expensive, but also more interesting in its properties. Good sound insulation is supplemented with low thermal conductivity. Doors with such a filling are much better in their characteristics.

Attention! To understand what type of filling is used by the manufacturer, knock on the door pattern. If the sound resonates, as in a drum, then they use a honeycomb. A dull and quiet sound, a sign of the use of a high-quality insulator.

And yet, if the manufacturer claims that he uses plates to fill the internal cavities, we recommend that you ask for certificates for this material. Cheap material may contain harmful additives that will “fonit”.

Types of exterior decoration

The choice of finishing material in the low-cost segment must be approached with particular care. This is due to the fact that for about the same money you can buy doors that differ greatly in quality.

You usually have to choose between different types of film coatings, the most inexpensive smooth doors with Fineline veneer cladding, and painted entry-level doors.

Let's start with the films:

PVC based films

One of the first to appear on the market. Very durable, difficult to scratch, can be washed even with a product. Initially, they were not very similar to natural wood and looked cheap. Now we have learned to make films with a very attractive pattern and relief. We advise you to take a look at the monophonic films that imitate painting, which are now popular.

Some companies are trying to replace polyvinyl chloride with more modern polypropylene, arguing the choice of toxicity of the first. It is believed that PVC in normal condition releases harmful chlorine into the atmosphere. In reality, this is nothing but a marketing ploy. The fact is that the polymer does “phonite” with toxic hydrogen chloride, but only during combustion, or when it is in a state of fine dust, which is only the case in factories where the material is produced and processed.

NB: the polymer is not toxic, but the substances used for decoration: dyes, softeners, bleaches, etc.d.

Polypropylene (PP) films

It is used more widely. It costs a little more than PVC, because it is more advertised. It goes on sale under various names:

They are polymers with identical composition. Unlike PVC:

- More modern - innovative,

- With high accuracy repeat the pattern of natural wood,

- More expensive.

Tip: if you have a choice between a coating option made of PP or PVC, pay attention to the thickness and aesthetics. The first criterion characterizes the strength of the product according to the principle "where it is thin, there it breaks." The second is expressed in a variety of textures, reliefs, shades: most companies try in this way to expand the range. As a result, each door looks different, although they have the same cover and do not differ much in price.

How to apply PVC and PP films

The canvas is placed in a special chamber with a vacuum press, previously lubricated with glue on a synthetic basis. Lay the film on the surface. The necessary conditions are created in the chamber to initiate the diffusion process. The result is a very strong connection - in fact, the canvas and coating become one. The advantage of polymers is that they stretch well, so they can be used to lacquer relief surfaces. Inexpensive milled doors are covered with just such films.

Recommendations: Of the pronounced shortcomings, we name one - the vulnerability of the door at the joints of the joints of the film coatings. Therefore: be sure to see how the door is made, how the joints of the coating look. Ask what the edge is made of, and if there is glass, pay attention to the presence of a sealant.

Laminated Doors

Now, when they talk about laminated doors, everyone presents the cheapest paper-finished doors. But in fact there are different options for this coating. They differ in the number of layers and have unequal strength.

The most budgetary option for coating is melamine paper. First, a drawing is printed on it. For greater stability, the base is impregnated with resins and coated with a protective layer. Doors with this coating can only be considered as a temporary option.

An improved version of lamination is the use of laminate. Film production technology looks something like this:

- The paper is glued in 2 layers,

- A drawing is applied to the surface (printed),

- They are treated with special protective compounds,

- Apply to a non-woven substrate during heating under high pressure.

The non-woven backing allows you to apply the material not only to flat surfaces, but also to bend around certain radii. This finishing method has one minus: the thicker the material, the worse it bends. Unlike PVC and PP films, which are applied in vacuum, it is impossible to cover the relief surfaces of panels with laminate, which imposes restrictions on the design of door leafs.

In general, doors with such a coating should be inexpensive and resistant to household damage, but again, it is necessary to check the thickness of the material and the edge before buying.

Finish films

Otherwise, they are called films with a finish effect on a dense paper basis. On a flat or textured surface by printing, a drawing is imitated that imitates natural wood, stone, and minerals. To protect against external factors, the surface is treated with resin. The last layer is applied varnish.

Due to the low cost and low mechanical strength, such coatings are used to decorate cheap paintings. The advantage of the finish film is its maintainability: if a defect appears on the surface, it is easy to remove and stick a new one, thereby updating the design.

Ecointerline interval

One of the most popular and modern coatings. Eco-veneer is different in cost and quality; it is produced in Europe, Japan and Russia. As they say in the brochures, in order to make the synthetic film as similar to natural wood as possible, and even to the touch and in relief, fibers of natural wood are added to it. Those. they take wood waste, grind it, bind it with polymer, press it several times with the desired relief, paint it and produce an eco-veneer.

In practice, eco-veneer is very similar to embossed paper with a polymer layer on the surface. There is a cheap one with a very thin outer layer, which practically does not differ from melamine paper. But accordingly, there is a quality, fat, expensive. The eco-veneer bends, but does not stretch. This means that there are no milled doors with imitation of panels covered with eco-veneer.

The eco-veneer can only be wrapped, so the collet system is considered an ideal design for applying this type of finish. As we already said, their advantage is that each element is wrapped separately before assembly.It turns out that there are no edges, and the joints remain inside the canvas.

Veneer fineline

The most inexpensive of natural materials. We will talk more about its properties later. Here we say that the cost of such material goes beyond budget models. But the simplest shield, smooth doors with veneers of such veneers, and varnished, can be bought at a price of 3000 rubles. To whom naturalness is important with a limited budget - pay attention to such models.

The average price segment. What to choose veneer or array?

Traditionally - classification by 2 key features:

| By design | Shield · Paneled |

| By material and type of finish | · High quality film: up to 1 mm thick, to ensure durability · Veneer (natural, fine-line) Enamel |

As you have already noticed, all three structural varieties of cheap doors are also present in the middle price segment. Indeed, they are produced by a similar technology, but they use materials one level higher in strength and wear resistance. An ordinary buyer can distinguish them from models from the "younger" category, for example, by weight. To fill such doors do not use cellular cardboard. In the lineup there are models from solid pine, chipboard, MDF that do not have cavities inside. They are more massive, because they consist of a denser, and therefore heavier material.

Instead of pine, some manufacturers use larch or birch plywood to strengthen the drawbridge models: this will significantly increase the strength of the door, while the replacement will increase the cost slightly.

We will talk about the coverings of constructions a little later - now let's understand what doors are called linear and paneled.

Natural veneer coating

The most expensive variety on the market. At the time, compare with the properties of the array - by design and moisture resistance. It is a thin section of wood. Elite varieties and not very valuable materials are used. The most common:

It precisely preserves the structure of the array, its pattern and color. Depending on the direction of cutting, it can be radial and tangential.

How to attach

The veneer is glued to the previously prepared frame. To obtain a stable connection, the hot pressing technique in a vacuum medium is used. As a last step, the surface is varnished to protect the veneer from sunlight and scratches.

Signs of quality veneer:

- Very smooth surface

- Chemical odors are present, but not very pronounced,

- The surface pattern is unique and beautifully selected,

- Uniform tinting without defects.

Veneer Fine-line (restored veneer)

Such designs sell at a price of 3-6 thousand rubles. fineline is the same natural veneer made by thinly cutting the surface of wood from fast-growing, inexpensive species. Popular options:

The manufacturing process is reduced to cutting layers, tinting, gluing and re-cutting. Ultimately, the material looks like a continuous coating with a pattern in the form of longitudinal lines.

Used in the manufacture of inexpensive veneered doors. Of the minuses - low mechanical strength. To enhance the protective functions of the model is covered with a thick layer of varnish.

Inexpensive array

In the middle price segment, buyers often prefer doors from a 100% array. These are mainly paneled canvases. Oak, ash and beech are not available for this money, so the doors are made of the following species:

- Pine, varnished, tinted, translucent coatings, wax or paint are very popular

- Pine inside, alder outside. This is done to increase surface hardness and strength,

- 100% alder. Due to the inexpressive pattern of the alder, it is often heavily tinted or generally coated with an opaque coating, such as enamel.

The properties of each material will be discussed later.

Enamelled

One of the most practical and diverse options is used to decorate the doors of any of the 5 above structures, as well as for expensive models made of natural wood.

- The technology provides very strong mechanical resistance and prevents from any damage occurring in the home,

- High moisture resistance and, as a result, the ability to install in bathrooms and in the kitchen,

- A wide selection of colors.

In the first two points, enameled doors surpass their veneered and film counterparts. Under the enamel layer, the natural texture of the material is not preserved, although this does not detract from the inherent aesthetics. Common decor options - art painting with persistent paints, filigree application of patina.

The strength of the doors is ensured by the use of complex technology for applying the composition. The process takes place in the spray booth. Experienced craftsmen are allowed to work.

To summarize the description of the characteristics of the methods of finishing interior doors will help the comparative table:

| Type of coating► | Laminate | Veneer | Ecointerline interval | PVC |

| Options for comparison▼ | ||||

| Environmental friendliness | «4» Depends on the quality of the substance with which the paper is coated. | «5» Slightly superior to other options. | «4» Depends on polymer quality | «4» The composition contains chloride, but its toxic properties are relative |

| Strength | “3” (if laminate is used) | «4» | «4» | «5» |

| Moisture resistance | “3”, well protected, but will defect when a defect occurs | “4”, can peel off, but only if the paintwork is damaged | "4", not sensitive to moisture | "5", absolutely moisture resistant |

| Difficulty of care | “5”, wet cleaning allowed, embossed surface makes cleaning difficult | "4", special care | "5", difficulties are associated with the relief surface | "5", not susceptible to water and special detergents |

| Price | Cheapest coverage | The tallest | It costs less than veneer | Low price (depending on the type of film) |

What to choose, natural veneer or solid wood?

The massif is solid beautiful wood with all the consequences, and the veneer is only its cut with a thickness of not more than 2 mm, which is glued to inexpensive MDF, chipboard.

The presence of many points of contact forces us to make a comparison between these materials. Veneered doors are the same natural, with perfect accuracy reproducing the texture of wood, therefore, as well as dear brothers, they are classics. The designs are similar in surface pattern, in some performance, but have a price gap, and sometimes quite significant.

| In defense of veneer | In defense of the array |

| Has more potential for modeling, color changes. From the material canvases are constructed that are impossible or disadvantageous to make from the array. Veneers are tinted in the desired color. They are arranged in different directions on the surface, combined with triplex glass, other combinations are invented that are not acceptable when choosing an array | For surface treatment, unique techniques are used that cannot be applied to veneers. For example, brushing with depth settings up to 2 mm. |

If the main selection criterion is appearance, it is hardly possible to prefer a veneer or an array. The layman will barely notice the differences. This can be done, for example, by comparing the weight of identical structures: veneer is easier. For interior doors, where anti-vandal protection and durability are not the most important qualities, a small mass is a plus, exactly, like a small price. If we talk about eco-veneer, add moisture resistance and minimal sensitivity to temperature changes to the bonus box.

As a summary: solid wood and veneer are related textures. If you do not want to overpay, choose inexpensive veneered models. Well, the elite oak, wenge or mahogany in its original form - for those who need to comply with the status.

| Attention! Crib! |

As for the prices, the limit values were distributed approximately like this (information will help to orient and understand if the seller is trying to give a cheap door to an expensive design):

• Laminated panel doors - from 1700 rubles. up to 3700 rub. (with glass inserts)

• Drawbars with eco-veneer coating: from 3300 rub. up to 6000 rubles.,

• Panel milled with PVC coating, "recessed" deep in the MDF panel: from 4000 rubles. up to 4500 rub.,

• Veneered (natural veneer): from 6,000 to 11,000 rubles. (depends on the complexity of the decor and the factory),

• 100% pine massif: from 4,500 to 10,000 rubles.,

• Painted: from 4000 to 7 000 rubles.

Pine

The wood is not dense, loose, with a porous structure, so it has a small weight.

| «+» | «-» |

| · The minimum weight of the finished structures, respectively, small loads on the supporting elements · High noise and thermal insulation (due to the porous structure) · Low hygroscopicity: pine is not very sensitive to changes in humidity and temperature, provided that the drying technology has been followed · Well amenable to processing - milling, sawing, tinting, dyeing, varnishing | · Softness, prone to scratches and chips |

Alder

Hardwood is not a valuable breed. Less common than pine, it still has a wide habitat, so wood is considered affordable and inexpensive. Positive characteristics:

- Not much more expensive than pine,

- The drying technology is not so complicated

- During the drying process, a smaller percentage of cracking and warping is observed,

- About 20% harder than conifers

- It is well processed with stains and other compounds due to its high hygroscopicity (for the same reason it is not used in its raw form),

- During operation, due to a change in humidity and temperature, a small voltage is created inside, so cracks appear extremely rarely.

Valuable, expensive breed. It grows slowly, mainly lives in the Caucasus and in the regions of Russia lying on European territory.

- High density (achieved due to the close arrangement of the fibers)

- The surface has high hardness, which increases over the years,

- Provides products with mechanical strength, beauty and durability.

The disadvantages of the breed are associated with high hygroscopicity. Doors are covered with protective compounds and are practically not used in their raw form. Neglect of the operating rules, especially if the drying technology has been violated, the wood is cracking.

Dense rock conducts sounds and heat well. Such doors should not be taken into account if you want to achieve perfect silence and thermal insulation (standard requirements for entrance doors, therefore, to increase the insulation level, thermal break technology is used).

Ash

- By strength, hardness exceeded the performance of oak,

- It shows high flexibility and resilience,

- More moisture resistant

- Faster growing

- Cheaper than oak.

Wood is negatively affected by the atmosphere, under the influence of the sun, water, winds, it collapses, however, these criteria should be taken into account when designing the entrance doors, therefore we are not considered as a minus.

In terms of hardness, elasticity, density it has similar indicators with an elite oak. Due to its homogeneous structure it lends itself well to processing - polishing, grinding. It turns out a flat, smooth surface without splintering.

Wood has the only drawback - high hygroscopicity (higher than that of ash, oak). Therefore, it is difficult to dry, so as not to cause cracking and warping. It requires special processing and operation in compliance with the main physical indicators. Due to the capricious nature, few manufacturers work with beech.

Which wood is prettier:

| Pine | Very interesting pronounced pattern with many stains of contrasting color. In order not to disturb the beauty, use colorless compounds for protection.Pine for some European design schools - standard |

| Alder | The uniformity, low expression of the picture is associated with barely distinguishable annual rings and rays. Suitable for tinting, enamel finish, which also reduces its hygroscopicity and increases moisture resistance |

| Oak | The beauty of the picture is achieved by large stains. Oak is easily confused with ash - the species are similar to each other. Therefore, in the manufacture of interior doors are considered relatively interchangeable. Moreover, in some respects ash differs favorably |

| Ash | The surface is covered with stains, like an oak tree, but does not have light stripes arranged in a chaotic order across the annual rings, which differs from its elite counterpart |

| Beech | Tree rings are pronounced, which appear on the surface in the form of parallel or wavy lines. The wood has a fine texture |

Slices of wood species are unique. On this basis, you can learn to distinguish them from each other. For installation in the homes of our citizens are more suitable doors from the array, growing in our country. They are superior to their foreign counterparts in price because they are cheaper and more adapted to our climate. Some will say - but what about the exotic? Studying the demand for those and other designs, we have to admit that Russians are more willing to install oak and pine doors, and are in no hurry to decorate houses, for example, with a foreign ebony tree.

How array characteristics affect the scope of application:

| Criteria | Where and when to use | Varieties |

| Moisture resistance | For installation at the entrance to the kitchen, bathroom | Alder, pine, ash, oak, beech (subject to appropriate treatment). |

| High risk of defects | In the children's room, in the apartment where there are pets | Oak, beech and ash as the most durable |

| The formation of sustainable aromas of freshly sawn wood | In a country house, in the country, in the apartment (eco style) | Pine: has a pleasant woody-resinous smell, exudes volatile, having prophylactic and therapeutic properties |

| For silence and warmth | In rooms requiring silence and good thermal insulation | Pine is the best, so they are placed in saunas |

| For a spectacular appearance | At the entrance to the living room, bedroom | The most beautiful texture of oak, ash, pine. |

| Economical options | On a limited budget | Pine, alder |

How to choose the doors to the bathroom, which doors are afraid of humidity

When choosing methods of protection against humidity, experts take into account that this negative factor affects objects in two ways:

- When air humidity changes, wood products tend to come to equilibrium with the environment according to this indicator, therefore they either absorb moisture if the atmosphere is saturated, or, on the contrary, give it away if the air is dry. At the same time, the dimensions of the product itself change, although if the door is made with high-quality and properly selected protection, this does not affect its functionality,

- When the structure is installed near a water supply point, for example, in the same bathroom. Water droplets often fall on the surface, and in the absence of exhaust ventilation, the canvas is covered with dense condensate.

It is easier to deal with the first factor: it is only necessary to foresee where the door will be installed, and choose a moisture-resistant model, carefully treated with varnish, enamel or coated with a film. It is worth paying attention to the joints and looking at the ends of the product: if defects are outlined at the edges, and the upper part is dense and left unprotected, they can become moisture conductors. Over time, the door will swell, if you do not eliminate the blemishes of production.

Which doors are more suitable for installation in the bathroom - consider common options:

| Array | Installation is allowed if the entire canvas is varnished and there are no chips or cracks on the surface. Due to the natural resin content, a pine tree is sometimes placed unprocessed at all. |

| Veneer | Similarly: in the presence of a continuous undisturbed varnish coating, water is not scary |

| Film doors | Not always a suitable option, depends on how the joints of the coating are made, the edge and which film |

| Ecointerline interval | Drawbars with high-quality eco-veneer normally tolerate high humidity |

| PVC | Record holder for moisture resistance if production technology is not violated |

| Laminated | Vulnerabilities are edges, and the coating itself may just swell |

| Enamel | The most acceptable option for installation in the bathroom |

What determines the insulation of interior doors

Any door has sound insulation, but they differ in the degree of protection. As a rule, in the production of inexpensive interior doors this factor is given secondary importance, therefore, in order to reduce the noise level of hollow doors by 5-10 dB, cellular cardboard is used as an insulating lining. Foamed insulating materials are used in the doors at a higher price.

Most of all, the glass insert affects the decrease in insulating properties.

. It is interesting:Examples of common noise sources and their indicators:

Whatever soundproofing option you choose, it should be remembered that the level of protection must correspond to or be lower than the degree of soundproofing of walls, ceilings and windows, because it makes no sense to install a “quiet” door into a room with “cardboard” walls.

The formation of a stable insulating cordon is carried out in four directions:

- Material selection.

- The use of a sealant.

- With glass inserts - thermal break technology ..

- Achieving a tight fit of the canvas to the box.

If all options have been exhausted, and the insulation is insufficient, you can use the so-called "Smart threshold" of the guillotine type. This device crashes into the lower end of the canvas, and in the closed position of the interior door overlaps the lower gap.

What do the specifications say? In Russian SNiPs there are no standards for soundproofing interior doors. Manufacturers adhere to European standards - 27 dB (according to DIN 4109).

How things really are:

| Door type | Sound insulation level |

| Veneered, laminated models | Most withstand the European standard norm of 27 dB, but provided that a sealant is installed in the design along the entire perimeter of the box |

| Array (oak, ash, beech) | Highest rate |

| Hollow Doors | Very low insulation |

| Sliding models with glass insert | The lowest level. Mostly carry a decorative function |

Note that simply by setting the input threshold, you will reduce the noise level by 2-3 dB, which is not a little in conditions of strong audibility.

How to determine the quality of doors in the store - practical tips for the average buyer

We know how important for an uninformed buyer "practical" practical advice from an experienced professional. We offer you a clear step-by-step instruction, which points out the signs of a poor-quality door.

Let's start with a discussion of the problems encountered with veneered models:

| Type of defect | Reasons for the appearance |

| Defects on the finish | Elements are poorly sanded or not every intermediate layer of varnish was ground. As a result - bubbles, pores, depressions |

| Smudges. The room smells of chemicals | Low-quality varnish was used. |

| Elements differ in color, the picture is ugly matched | The surface is covered with low-quality veneer with defects. |

| There are differences in the color of the coating on the canvas and at the edges | Edge defects. The technology is broken, because the shade on the entire surface of the structure must match, and the door itself should look like a model from a solid array |

| In the places of fastening of panels, at glazing beads, near the glasses there are gaps, the edges do not fit tightly, the details are loose | Poorly completed assembly |

| The sample has defects visible to the naked eye: scratches, cracks or other evidence that the canvas has been restored | Unstable veneer was used or the technology was broken during gluing |

What does a poor-quality door look like? from array:

- Geometry broken: check the dimensions on both diagonals. The error is allowed up to 2 mm,

- Shaggy due to poor sanding. The presence of protruding fibers, chips can be seen in the corners,

- There are small cracks on the massif; large gaps are left between the lamellas.

Signs of substandard stained doors:

- Poor assembly: large gaps appear between the parts, which are especially clearly visible on painted structures. Look like big cracks,

- The facade is different from the edge: in a quality door, all surfaces must be the same color. Perhaps you are offered a door covered with a film,

- There are unpainted areas. It can be seen that the edges and chips were separately painted over. Sometimes under a layer of paint hide dust in the corners.

Do not buy doors covered film, if a:

- Already on the sample there are places with a peeling edge,

- Elements of plinth constructions are movable,

- In the places where the parts adjoin, there are large gaps,

- There are smudges of glue on the surface, the seams are crooked, the sealant is not installed or it is glued inaccurately and extends beyond the edges,

- With a little pressure, the canvas bends: this indicates the use of very thin MDF and the void inside.

A few more tips - how to choose an interior door:

- Ask to provide a sample in the context - so understand what is inside.

- The upper end will tell a lot, which often remains untreated.

- Try to estimate the weight of the product in order to understand whether a solid sheet has been used or cardboard is inside.

- Carefully examine the surface, look at it from all angles. It should be smooth, have a uniform color.

- If the door has a glass insert, ask what kind of glass is used, how it is installed.

- Try to shake the product silently. If you hear a rattling sound, then the parts are not securely connected to each other. A quality door is a monolith.

We check the quality of components: box, platbands, etc.

All elements of the door structure are divided into 3 groups:

That is, everything that is outside the canvas refers to molded products. Reliability of all designs directly depends on their quality. What is included here? What to look for when buying?

What is called molding:

- A box

- Additional timber,

- Platbands,

- Capitals, cornice.

Box

The same frame that is installed in the doorway. The holding element, hardware is attached to it, the canvas is hung. On the front of the box, from the edge where the door closes, there is a ledge. This is the narthex on which the seal is usually mounted. There are 2 types of boxes:

- Ordinary

- Having a special groove for installing telescopic platbands with doborniki.

The second model is more practical and easier to install, but costs a little more.

For an ergonomic arrangement of the door in the opening, a hidden duct is used. As a result of installation, such a door as if fits into the opening and becomes part of the wall. To enhance the effect of the cloth pasted with the same material as the adjacent surface. Such a door becomes visible only in the open position.

The material for the production of boxes is selected taking into account the type of canvas (you can see what it is made of by looking at the end part):

- If this is an array, then the box should be made of the same wood,

- If the door is covered with veneer, then the box is designed in the form of a sandwich, superimposing on each other layers of timber from pine, MDF and other durable glued material,

- Boxes in inexpensive doors are made of MDF,

- Moldings for lightweight structures are designed specifically for the weight of the product.

Additional timber

Factory door frames have a standard width of 70 mm. It is good if it lays down to the entire depth of the opening, which is rare. In most cases, the walls are wider. To increase it to the depth of the opening, use an additional beam (professionals call it an additional beam).

The structural element is a bar with a rectangular section. Width is selected individually. More often in factories produce dobnik 100, 150, 200 mm. The wizard will adjust the width during installation if 20-30 mm are unnecessary.

Platbands

Decorative elements. Position along the edges of the installed box. Hide formed gaps, foam, fasteners and other elements between the opening and the box. Platbands are of two types:

- Normal: standard strips of different widths,

- Telescopic: they have a section in the form of a corner. The front part closes the gap between the wall and the box, and the adjacent side leaves a groove in the end part of the box. Sometimes, if the clypeus is not wide enough to reach the box, an additional element is inserted between them.

Docking platbands is carried out in three ways:

- Using square sockets,

- Butt, at an angle of 45 degrees,

- Butt, at an angle of 90 degrees.

To enhance the aesthetic effect, platbands are made convex, carved, and decorated with grooves. They are made of the same material as the door itself.

What interior doors are better to buy