The thickness of the drywall determines the functional purpose of this building material. Thin sheets go to the ceiling lining, thick walls and interior partitions are trimmed. That is why any GKL standard size should be known to any buyer of this finishing material. Otherwise, a heavy ceiling will collapse at the most inopportune moment, and thin walls will crack under the weight of a mirror or interior decor.

Gypsum plasterboard (GKL) appeared on the domestic market in the middle of the twentieth century. However, a patent for this building material was registered in the 19th century, describing the technology of gluing 15 layers of paper and a layer of dry gypsum plaster. Modern GCR does not differ from its ancestor from the 19th century - it is the same flat sheet obtained from gypsum and reinforced with a paper wrapper. Moreover, the size of the drywall sheet depends on its functional purpose.

In the century before last, this material was used only in interior decoration and produced in paper mills, so the size of gypsum plaster depended on the requirements of the customer. Nowadays, the scope of application of "dry plaster" has expanded, and the parameters of the sheet have undergone optimization and standardization. In the twenty-first century, drywall factories produce the following varieties of building and finishing materials:

- GKL is, in fact, the same “dry plaster” from the nineteenth century, used as an internal finishing material. From it make a binder for the ceiling, interior partitions or used for interior decoration. Therefore, the thickness varies within a centimeter, and the height corresponds to the standard level of the ceiling.

- GKLV - a modified version of the "dry plaster", weaned to fear moisture. Due to this, paper-wrapped cardboard began to be used in previously inaccessible places - in bathrooms, in kitchens, in toilets and other damp areas of the house. The dimensions of moisture-proof gypsum board do not differ from the dimensions of the usual version, because before us is the same finishing material, only with a wider scope.

- GKLO is a special version of ordinary material that is not afraid of flame and high temperatures. This is a completely different drywall. The thickness here is much more than standard and reaches 3 centimeters. And it is used in the decoration of fireplaces and other hot places.

- GVL and GVLV is already the next generation of "dry plaster". Gypsum-fiber sheet developed the idea of gypsum plaster by reinforcing the inner layer of the plaster with cellulose fibers. Thanks to this, he gained strength and abandoned the cardboard wrapper. Moreover, moisture-resistant material (GVLV) is not afraid of not only loads, but also water. From the previous generation of GVL building materials, only standard sizes were obtained.

There is also an “acoustic” drywall - a finishing material with reduced sound permeability. Because of this, it costs more than the usual option and is used only in special cases.

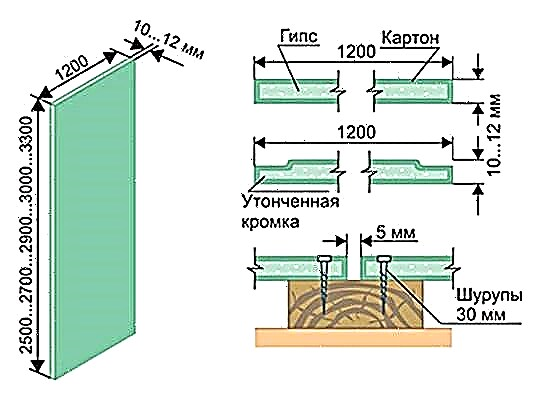

The thickness of the drywall determines the scope of its application. Moreover, such panels are most often used for finishing ceilings, walls and partitions. As a result, the following picture is observed. The thickness of the standard sheet ranges from 6 to 15 millimeters. Moreover, the size of 6 and 6.5 mm is only in a flexible sheet reinforced with fiberglass. It is used for the construction of arches and other complex structures. The thickness of the ceiling material is exactly 9.5 mm. On the partitions there is a panel of 12.5 and 15 mm.

The modified GKLV parameter does not differ from the standard. After all, this is the same building material, only with increased moisture resistance, so here we see a similar size range - 9.5-15 millimeters. Such material can be used to hem ceilings, upholstery walls and partitions, using GKLV in the dampest rooms.

The thickness of drywall formats GKLO, GVL and GVLV reaches 25 and 29 millimeters, with a minimum value of 9.5 and 12.5 mm. Moreover, very dense panels are released only by special order. This is usually a trademark. Giprok offering flame retardant and heavy duty material for special occasions. Therefore, the dimensions of the gypsum board can be chosen by the buyer who wants to assemble a very durable partition for decoration with natural stone, wall behind the fireplace or heating boiler.

Other dimensions of this building material are not very diverse. The length of the sheets fits into the size range from 2 to 4 meters. Moreover, the most common size is 2.5 meters. Due to the different height of the ceilings in our houses and apartments, sheets of 2.7 and 3 meters use their share of popularity. Larger materials at 3.5 and 4 meters are very rarely found on open sale. Usually they are ordered in factories for specific purposes.

The width of the situation is even simpler - 0.6 and 1.2 meters. Moreover, the first size is much less common than the second. Therefore, 1.2-meter width is perceived as the standard size of a standard sheet.

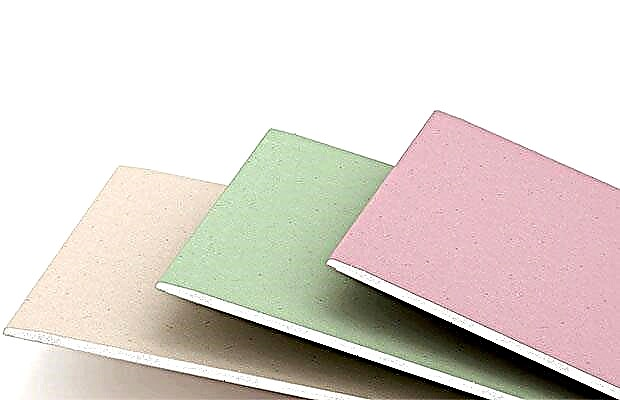

How to find out the nature of a leaf and distinguish GKL from GKLO? Everything is simple here:

- ordinary sheets are pasted over with white cardboard,

- moisture resistant material is painted with green color,

- the fire-resistant version is pasted over with pink cardboard,

- fire-resistant and moisture-proof panels are painted in pink color and marked with green inscriptions,

- the gypsum sheet does not have a wrapper at all.

Drywall Standard, Moistureproof and Fireproof

As a result, to decide, look at the wrapper and color of the inscriptions and select the option you need. Which one? We will talk about this in detail in the next paragraph.

Are you standing in an arch, pillar or multi-level ceiling of complex design? Pay attention to the 6 mm flexible drywall from Giprok. Such a sheet can be folded into a tube without the risk of damaging the structure. A slightly thicker, almost centimeter sheet in this case does not fit. He bends a little, but it is easy to break, violating the integrity of the entire wall, ceiling or column.

Hem flat ceiling? Buy 9.5 mm sheets from ordinary or moisture-proof drywall. They do not load the structure and have high rigidity. Thanks to this, you can reduce the number of profiles in the frame. A flexible option is not useful here - it can sag without a serious crate. A deeper version will require even more reinforcement of the frame, since the difference between millimeters results in a difference in weight, measured in tens of kilograms.

Sheathing the walls? Choose sheets with a thickness of 12.5 or 15 millimeters. They have good rigidity and will help level the surface even without profiles. It is not necessary to lay something more serious on the wall, since a nail or a self-tapping screw will not be driven in or screwed into gypsum, but into the dense building material of the supporting surface - brick, concrete or wood.

Are you building interior partitions? Stop on a gypsum sheet from a thickness of 15 millimeters. Otherwise, your wall will not be functional. You cannot screw a screw into a thin GKL, and you will not hang a picture or a shelf, and a 2-centimeter GVL allows you to do this.

Drywall Thickness for Walls

Drywall is a building material widely used for repair work. They align the walls, create partitions, arches, ceilings of incredible beauty. It is applicable for creating shelves, niches, interior products.

Drywall is a building material widely used for repair work. They align the walls, create partitions, arches, ceilings of incredible beauty. It is applicable for creating shelves, niches, interior products.

The thickness of the gypsum for the walls plays an important role. How to choose the right dimensions of the material, on which the selection parameters depend?

Material benefits

Before you buy GK-lists you need to familiarize yourself with the pros, cons of the material:

- Thermal insulation. Smooth surface material saves on heating. This is especially true if the insulation is laid under the GCR.

- Flexibility. Drywall bends under a certain radius, this allows you to make decorative elements.

- Fire resistance. When a room ignites, not covered with GKL finish, only the top layer will burn out - gypsum does not burn.

- There are certain types of material used in the kitchen, bathroom, on the balcony.

- When leveling the wall with material, communications, wiring and other cables are carried out behind the sheets.

With all the advantages of GCR, there are disadvantages:

With all the advantages of GCR, there are disadvantages:

- fragility of the material. It breaks and crumbles, so installation work is carried out with caution,

- if you set the usual look of gray in the kitchen or bathroom, it will absorb a lot of moisture and subsequently deform,

- Before installing the gyrocock on the surface, it is necessary to determine what thickness it should be, whether the wall will become heavier,

These pluses show that the use of GCR is beneficial for leveling surfaces and creating other surfaces.

What drywall is better to sheathe walls in a room: characteristics

Before giving an answer to the question, it is necessary to list the external factors affecting the future design.

Before giving an answer to the question, it is necessary to list the external factors affecting the future design.

- Humidity indoors. With increased humidity in the room: kitchen, bathroom, attic, corridor, a moisture-proof sheet is used - GKLV green.

- Temperature condition. With sudden temperature jumps, drywall can shrink and expand. This will cause cracks. The leaf will burst.

- If the wall is next to the existing fireplace, it is necessary to carry out installation with refractory material. It resists heat and does not change its original appearance.

The purpose of the surface matters. If decorative finishing with hyprocom with curly elements is supposed, then one sheet thickness of 12.5-9.5 mm is used. But, given the hanging shelves, TV, paintings, large mirrors - use different material with a certain thickness of up to 24mm. In some cases, mount the skin in 2 layers.

Features

The classic version of the material is a sheet obtained by pressing, consisting of a gypsum core and two layers of cardboard covering the main layer on both sides. Modification or types of GCR depend on the scope of its application, which is fundamental in the development of sheet thickness.

According to the classification, the thickness of the product determines the place of use. Wall view drywall refers to the most common types of this material. Wall cladding, creating an interior partition is carried out using this particular type. The thickness of the wall sheet depends on the loads imposed on it.

If the built-in partition will only perform a decorative function in the future, then it is not necessary to install thick sheets;

Ceiling view drywall compared to wall has a smaller thickness, and there is a simple explanation. The material, regardless of the type of structure, is attached to the suspension frame, therefore, in order to prevent collapse of the structure, the weight of the sheets should be less than that of specimens intended for partitions and leveling the walls.

The thinnest species arch GKL. It is used if you want to make a design with curved shapes. Due to the smallest thickness compared to ceiling and wall types of drywall, allowing it to bend, it is possible to assemble models with wave-like, domed or round shapes. Using arch GKL, you can create structures with even the smallest bending radius without creases. This type differs from all not only in thickness, but also in composition, instead of a paper layer, it has layers of fiberglass, which give strength to the sheet, and also affect its weight.

There are other parameters that characterize drywall and affect its thickness. Depending on the climatic parameters and the functions assigned to the design, GKL includes various components, due to which the sheet gains resistance to various types of exposure.

Moisture-resistant appearance of the sheet is marked as VGKL and has a green surface color. It is used for structures installed in rooms with a high level of humidity. Its resistance to water is explained by the presence in the composition of the hydroprotective solution, impregnated impregnation, which inhibits the rate of absorption of moisture and antifungal agents that prevent mold. The use of VGKL in bathrooms, pools, saunas is also justified by the fact that it has a sufficient thickness that allows facing the surface with ceramic tiles or artificial stone.

Fireproof type of sheet marked by manufacturers as Hklohas a pink color. In addition to gypsum, the composition includes components such as fiberglass and clay, and there is also a liquid in the form of crystals. Each component has its own purpose. Crystallized liquid prevents the spread of fire, and fiberglass and clay help maintain shape after burning cardboard layers. The fire resistance of such a sheet is within 45 minutes from the moment of ignition. This type of sheets is used if you need to make a ventilation shaft, duct, a portal for a fireplace or a duct for electrical wires.

Sheets marked GKLVO have all the qualities characteristic of moisture-resistant and fire-resistant species.

It belongs to a special kind gypsum fiber sheet or GVLcharacterized by increased strength. In addition to gypsum, its composition contains cellulose fibers, thanks to which it is able to withstand significant weight loads. Another distinctive feature of the fibrous product is the absence of cardboard layers. A type of ordinary fibrous sheet is GVLV, which can withstand not only significant loads, but also with resistance to moisture.

The listed types of drywall belong to the main groups, more popular and more often used. But there are other species in which thickness is of particular importance, since the scope of their application is specific. The composition of such sheets contains additional layers that determine their purpose. Noise isolators, heat insulators, absorbents of electromagnetic waves, as well as products with a wind protection function used in cladding of buildings, have a dense structure and have a higher thickness compared to conventional sheets.

Advantages and disadvantages

Plasterboard sheets occupy a leading position among other finishing materials by no means by chance, they have many positive qualities, thanks to which they gained their popularity.

Working with them is quite simple, a person without special professional skills can cope with the installation of a conventional design. It is easy to cut and screw it to the frame, the main thing is to make preliminary marks correctly. Thanks to the various types of sheets, it is possible to collect not only simple-shaped boxes, align walls and ceilings, but also to build beautiful partitions with arches, to mount two- and sometimes three-level ceilings, using for this purpose copies of various thicknesses.

Plasterboard sheets, regardless of the scope of application, are lightweight, and therefore the structures built from them do not press on the floor if installed in an apartment, and do not adversely affect the foundation if the structure is installed in a private house.

Regardless of the components that make up the gypsum plasterboard, this material is fireproof, because the basis of any sheet is gypsum, and it does not apply to combustible materials, on the contrary, it contributes to the attenuation of an open flame and does not extend it to other materials.Fire safety is the main argument in favor of the construction of fireproof partitions in the premises.

All types of drywall, regardless of thickness and purpose, are environmentally friendly finishing materials, they do not contain components harmful to human health, which means that you can mount structures made of gypsum plaster in any room.

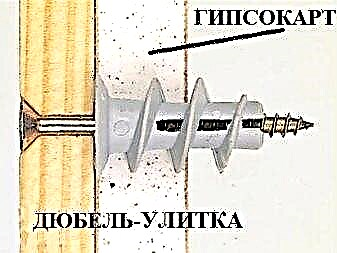

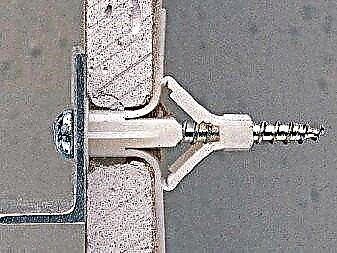

But this material has its drawbacks. Due to the fact that gypsum board is still based on gypsum, its strength is not as great as we would like. It will not work to use the surface of the sheet for hanging objects with an impressive mass. Shelves made of solid wood with a large number of books, wall cabinets, plasma panels and other items weighing more than 10 kg usually require special fasteners, and if the mass of the item is higher than 35 kg, then fastening is possible only to more durable materials.

Do not forget that gypsum, which is the basis of any sheet, has a high degree of hydrophobicity, so there is always a risk of losing shape due to soaking.

Even moisture-resistant sheets with direct and prolonged contact with water can lose their stiffness, not to mention conventional gypsum plasterboards, so all types of structures constructed using plasterboard sheets should be indoors.

Dimensions

The scope of drywall is very extensive. Given this fact, manufacturers produce sheets of different thicknesses, widths and lengths. When buying sheets, it is necessary to take into account all parameters and select the material based on the location of the future design.

Plasterboard sheets are not particularly diverse in width and length. The length of sheets produced by manufacturers, today is in the range of 2-4 m. This run-up is due to the difference in the height of the ceilings in the houses. A height of 2.5 m is considered standard, but also products with a length of 2.7 and 3 m are no less popular and in demand. Least of all on sale there are specimens with a length of 3.5-4 m, they are usually made to order.

The width of the sheets are of two types - it is 0.6 and 1.2 m. The less popular and popular width is 0.6 m. The second value of 1.2 m is found and used more often, therefore it is considered to be its standard.

The thickness range of the drywall sheets is in the range of 6-24 mm, but there are more dense products, mainly used for finishing floors, their thickness reaches 50 mm (maximum). The thinnest specimens have a wall thickness of 6-6.5 mm (minimum value), are used to build structures with bends on the ceiling surface.

For walls, sheets having a thickness of 12-16 mm are used, and for the ceiling, 9.5 mm is sufficient. The optimum thickness for a drywall construction is considered to be 12.5 mm.

The use of sheets of different thicknesses depending on the location makes sense, because the thicker it is, the more weight it has, which means that the higher the structure, the thinner the sheets will be required for installation.

How to choose?

In order to choose the right drywall, first of all, its purpose and the planned load on it are taken into account.

If it is necessary to install the design in the bathroom, it is best to purchase moisture resistant sheets (GKLV). The thickness of the product should be selected according to the location. For niches and partitions, sheets from 12.5 mm to 15 mm are most suitable, and for the ceiling surface, sheets with a thickness of not more than 9.5 mm with a similar resistance to moisture. Do not play it safe when using products with a thickness of more than 9.5 mm for the ceiling surface, since there is a possibility of collapse of the installed structure, because sheets with a thickness of 12.5 mm have more weight. In addition, their cost is slightly higher, which means that much more money will be spent on the purchase of material, and in the event of a collapse, it will be wasted.

To create a two-level ceiling with bends and arches, you should buy a special thin arched drywall, and for baskets with simple shapes, a normal ceiling is suitable.

For outdoor applications and in rooms with a high degree of humidity, sheets with gypsum fiber resistant to moisture (GVLV) are more suitable.

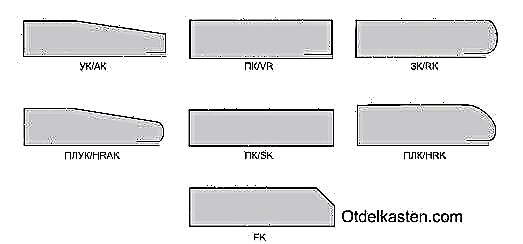

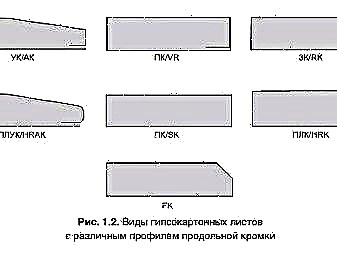

When choosing sheets by thickness, it is necessary to pay attention to the edge of the material. Different types of edges are produced by manufacturers for a reason. Subsequent processing of joints depends on what kind of edge the sheet has.

Instances with a straight edge are needed if the sheathing of the structure is conceived as two-layer, and they are used as the inner layer, where it is not necessary to glue and putty the joints. Products with a refined edge are purchased if it is planned to use reinforced tape at the joints in the future. For sheets with a rounded edge with a width of 5 mm, the use of reinforced tape at the joints is not necessary if it is not planned to putty on the entire surface of the sheet.

When selecting sheets, it is important not only to take into account their purpose and location, but also to correctly calculate their consumption. Knowing the area of the sheathed structure, it will not be difficult to do this.

The partition, sheathed with plasterboard measuring 5x 2.5 m, has an area of 12.5 m², and the area of one standard sheet measuring 1.2x 2.5 m is 3 m². In order to form a partition, the frame is sheathed on two sides, which means that the area covered by sheets doubles and becomes equal to 25 m². The number of sheets required is calculated as follows: 25: 3x1.2 (correction factor). The resulting number is rounded up; in our case, 10 sheets are required.

If the structure needs to be sheathed in two layers, then the size of the structure must be multiplied by 4. For ceiling surfaces, the flow rate is calculated in a similar way, and for mounting the sides located around the perimeter, a few more cm are added, usually 10-12 for each sheet width.

Tips & Tricks

The choice of a quality gypsum plasterboard should be approached very thoroughly and extremely deliberately.

Focusing on the parameters when buying sheets, you should definitely know not only the amount of material, but also take into account the dimensions of the room in which the structure is mounted. In small rooms with low ceilings and small area, it is very difficult to work with sheets that have large sizes. It is better to purchase products with standard sizes, especially if the installed structure does not have a pronounced specificity. In addition, the cost of such sheets is much lower than that of bulky items.

For the same reason, you should not spend money on products with specific properties, if there is no reason for that. Fire-resistant and moisture-resistant material is more expensive than usual, and the sheathing of a structure located in a place dry and remote from fire and water will not work, except for unnecessary expenses. It is better to purchase a regular drywall with a thickness corresponding to the location.

Drywall should be bought from proven and well-established companies specializing in building materials and providing a long guarantee while observing operating standards.

You should not purchase material in natural markets, there is a risk of a purchase that does not meet the declared technical characteristics, and the storage conditions in such places are usually violated, which invariably leads to a decrease in product quality, which, in turn, affects the life of the whole designs.

About the partition of the smallest thickness: 50mm and the installation of drywall, see the next video.

Types and features of drywall partitions

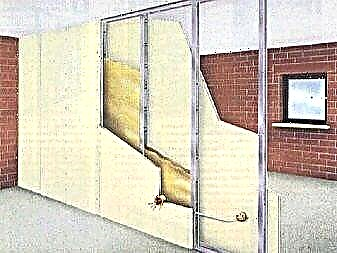

The design for dividing the space in the room is being built on the basis of a frame system of wooden beams or metal profiles. The outer skin is made of gypsum board in one or several layers, the internal space serves to accommodate thermal insulation and conceal communications.

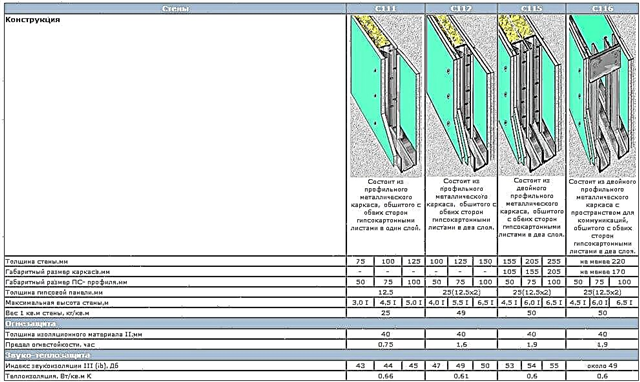

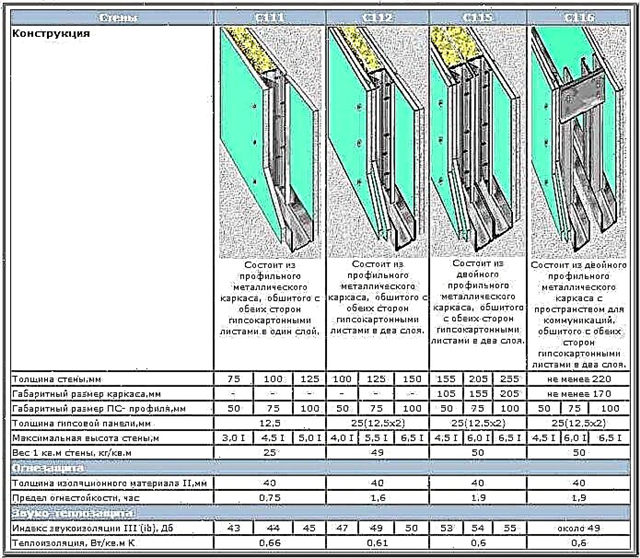

To select a suitable solution, it is recommended to rely on the classification proposed by the well-known manufacturer of construction and finishing products - KNAUF. Structural separation includes several options with special labeling.

Partitions are classified by thickness, height, presence or absence of sound insulation, and the number of gypsum plaster layers, but the general structure construction scheme remains standard

Partitions are classified by thickness, height, presence or absence of sound insulation, and the number of gypsum plaster layers, but the general structure construction scheme remains standard

From a metal profile

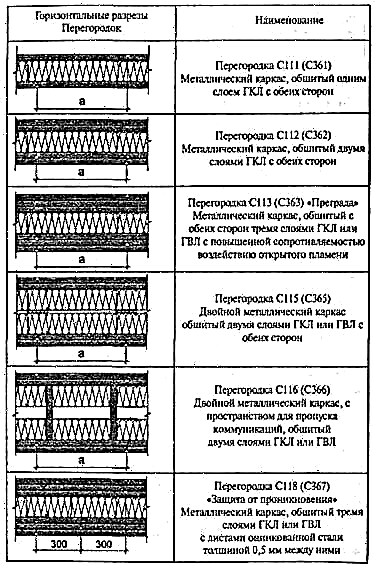

- C-111. This is the standard variation that occurs most often. The design is the basis of galvanized profiles CW, belonging to the rack category. Exterior finish on each side is carried out by sheets of drywall mounted in one layer, the inner part is filled with mineral insulation. The resulting structure meets all fire safety standards and is suitable for facilities that do not need serious sound insulation. The weight of the composition is about 28 kg per 1 m3, the maximum height is 8 m.

- S-112. At the heart of the frame is a rack-mount metal profile. Unlike C-111, two layers of gypsum board are hemmed on each side. The void is also filled with mineral insulation. The design provides good soundproof characteristics: according to the RW index - up to 50 dB. Significantly higher fire resistance. The variation is suitable for capital construction and the usual redevelopment of private houses and apartments. Maximum height - 9 m, weight - 53 kg / m3.

- S-113. The base consists of galvanized elements, which are installed in a classic way in a row. Exterior finish for each side is increased to 3 layers, the inner space is filled with mineral wool. The design has good heat-insulating and sound-absorbing properties. The maximum height is about 9.4 m, weight - 78 kg per 1 m3.

- S-115.1. The variety differs significantly from the previous categories in the structure of the frame system: it is performed on the basis of two rows of profiles. The outer lining has 2 layers on each side, the voids are filled with mineral products. The design is able to withstand significant loads and has excellent sound and heat insulation parameters. The mass fluctuates within 57 kg / m3, the maximum height is 6.5 m.

- S-115.2. The base structure is an exploded frame. This configuration includes two rows of galvanized parts, separated by drywall, which increases strength. The maximum height increases to 9 m, the weight is 69 kg per 1 m3. Internal filling is standard.

- S-116. Such a partition is created if necessary to lay supplying or diverting communications: water and sewer pipes, heating. The frame is created in two rows at the desired removal of rack elements. The connection is made using GKL segments or metal jumpers. On the outside, two layers of drywall are hemmed. Sound insulation according to the RW index is 50 dB, fire resistance is 60–80 min. Height ranges from 4.4 to 6.5 m, weight - about 61 kg / m3.

- S-118. The strengthened configuration, belongs to the class "Protection against penetration". The structure is similar to the C-113 variety, but galvanized steel sheets with a thickness of at least 0.5 mm are added between the layers of drywall. Recommended height - up to 9 m, weight per 1 m3 - 86 kg.

For the arrangement of interior partitions in an apartment, a modification of S-111 or S-112 is sufficient, more complex and reinforced types of structures are designed for installation in office and industrial premises

For the arrangement of interior partitions in an apartment, a modification of S-111 or S-112 is sufficient, more complex and reinforced types of structures are designed for installation in office and industrial premises The galvanized profile allows you to perform work even in rooms with high humidity.

From a wooden bar

- S-121. It is made of wood material with a maximum humidity of 12%. The frame is made in the form of a frame with the middle of the rack parts. The casing is mounted in one layer, the thickness is individual. Height should not exceed 3.1 m. Weight is about 32 kg per 1 m3.

- S-122. A reinforced version of the previous version. The lining includes an additional layer of drywall, the inner space is filled with mineral material. The structure has good sound and heat insulation. The maximum height is 3.1 m, the weight per 1 m3 is about 57 kg.

Regardless of the type of construction, the most suitable types of gypsum boards can be used for work. Combination of products is allowed taking into account compliance with environmental standards and fire safety.

Wooden frames for the GKL partition were designed for wooden houses; for the arrangement of the structure, a forest with a humidity of not higher than 12 - 14% is used

Wooden frames for the GKL partition were designed for wooden houses; for the arrangement of the structure, a forest with a humidity of not higher than 12 - 14% is used

Drywall

For vertical structures, strength and the load created are of great importance. The main dimensions of the plate are standard: width - 120 cm, length - 200, 250 and 300 cm.

Partition drywall sheet thickness:

- 12.5 mm. A classic indicator for creating a simple and decorative design.

- 15 mm Such slabs are suitable for partitions that experience a load of up to 50 kg / m2.

- 18 mm This material is used to increase exposure to 70 kg.

In situations where it is necessary to distribute more weight, a two-layer structure is used, which is able to withstand a significant load provided that the frame is strengthened.

Depending on the type of room or site, a suitable variety is selected: ordinary, moisture resistant or fireproof. Universal is a special variation - GKLVO.

Important! Products must be labeled and certified safety.

Profile

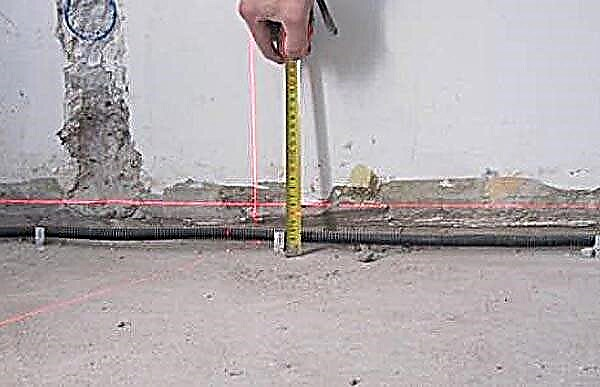

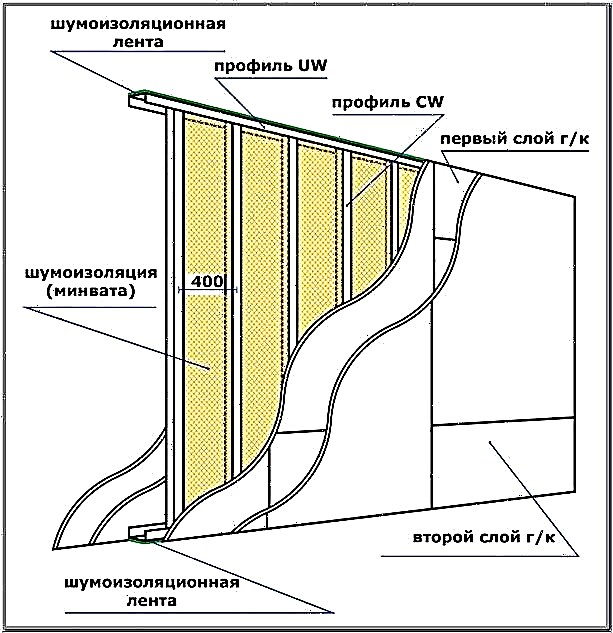

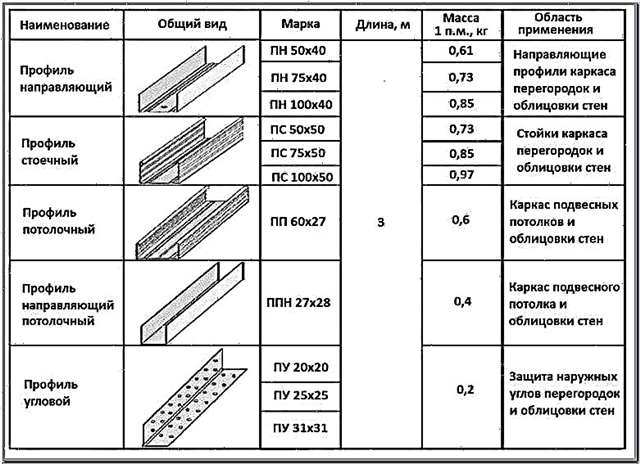

Installation of drywall sheets takes place on a frame system, which is built from the rack parts CW and UW guides.

In the domestic marking, the CW profile is designated as PS (rack profile), and the UW model is marked as PN (guide profile)

In the domestic marking, the CW profile is designated as PS (rack profile), and the UW model is marked as PN (guide profile)

The size range of products includes several basic variations. When determining the optimal width, you must be guided by the following recommendations:

- 50 and 75 mm. Such elements are used for mounting simple structures that perform dividing or decorative functions. A wooden beam is used to reinforce.

- 100 mm An excellent solution for creating a complete wall with insulation and sound insulation.

- 125 and 150 mm. Professional profiles that make it possible to withstand heavy loads.

There is a kind of UA, which can be used as a support when installing equipment and doors.

Minimum thicknessprofile for standard partitions - 0.5-0.6 mm, for those in need of reinforcement - from 0.7 mm.

Calculation of the thickness of the structure

To do everything right, the basic parameters must be determined at the preparation stage.

The most common options are:

- 75 mm. This indicator is the minimum that is obtained from the thickness of the profile (50 mm) and two GCR layers of 12.5 mm each. The corresponding type is C-111, 25 mm is added for C-112.

- 175 mm. Racks - 100 mm, 3 layers of drywall on each side - 75 mm. This thickness is typical for the design of C-113.

- The indicator for the variety C-115 must be calculated individually. With a profile thickness of 75 mm, the value is multiplied by two and the GCR thickness is added - 50 mm (12.5 * 4). Thus, the width of the wall is 200 mm. With racks of 100 mm installed in two rows - 250 mm.

A more complex calculation is made for the partitions in which communications will be located. In this case, not only the dimensions of the profiles and drywall are taken into account, but also the parameters of the pipes with a margin.

Drywall Classification

All sheets are a kind of “sandwich” of two layers of durable cardboard and a solid gypsum core. Impregnation of the coating with special solutions and the addition of various additives to the "core" make it possible to obtain various functional characteristics. To know how to choose the right drywall for walls, you need to familiarize yourself with its main types:

- GCR - a common material - is used in the decoration of residential and office buildings with normal humidity and temperature conditions. GKL sheets are distinguished by cardboard, painted in gray, as well as blue marking.This view can be installed on the wall in various ways, which we will talk about later.

- GKLO - fireproof - has increased resistance to open fire. Such drywall is mounted on walls in rooms that have special requirements for observing fire safety standards. The material is gray cardboard and red marking. Standard sizes of GKLO sheets are 2500x1200x12.5 mm. The weight of the plate is 29 kg.

- GKLV - moisture resistant - neutral to high humidity (more than 70%), undergoes antifungal treatment. Sheets of wall-mounted moisture-proof drywall are painted green and have a blue marking. Since it is intended for further decoration (tiling, etc.), it must be installed on the frame from the profile.

- GKLVO - moisture and fire resistant - combines all the properties of the above materials. It is used for decoration of premises that have high fire safety standards and have high humidity. The color of the sheets is green with red markings.

- FIREBOARD - a type of wall "refractory" drywall, which has increased resistance to flame. The thickness of the sheets is 20 mm, and the weight of one plate is 31.5 kg. Due to the relatively large mass, this type is recommended to be mounted on a metal frame. It can be distinguished by the red color of the cardboard and the same marking.

The length of GKL sheets of all types can be 2000, 2500, 3000, 3500 and 4000 mm, and their most common width is 1200 mm. There is no standard size of drywall wall: for example, the thickness of the plate depends on the type of material and the features of its application and can vary from 6.5 to 24 mm.

For the decoration of wall surfaces, sheets with a length of 2500-3000 mm are mainly used. The width of the plates is 1200 mm, and the thickness of the drywall for the walls can be 9 or 12.5 mm.

Scopes of various types of GCR

Each type of our finishing material has certain characteristics and has special properties that must be considered when choosing it for a single room.

- In order to align the wall surface of an office or a room in a residential building, it is enough to use ordinary GKL for “dry” rooms.

- Installing drywall on the walls of bathrooms, showers, bathrooms, basements or loggias and terraces will require the use of material with waterproof properties - GKLV sheets.

- The fire-resistant type of GKLO is applicable in the decoration of industrial and public premises - workshops, halls, corridors and vestibules. It is also used when equipping niches for laying communications.

- When choosing drywall for the walls of a kitchen room, preference should be given to GKLVO - refractory and waterproof type. It can also be used to equip fire barriers.

What profile is needed for drywall for walls

The guide strip made of galvanized metal PN (UW) is used as the basis of the entire wall frame. It is attached to the wall and ceiling so that the fixation is mirrored, without shifting. They also need to be fixed to opposite walls. You will get an even quadrangle creating a plane. Mounting is done with dowels, nails, a distance of 20-25 cm from each other. 5 cm should be retreated from the edge of the profile and secured with the first dowel-nail.

After that, direct suspensions that serve as the holder of the rack element are fixed to the wall according to the marking. For fixing, dowel nails are also applicable.

In guides PN (UW) insert rack-mount PS (CW). They are fixed with self-tapping bugs. Flatness of the plane is regulated by the level and rack mounted to the suspensions with self-tapping screws.

For structural rigidity, transverse ones are made every 40 cm. They are cut from rack-mount PS (CW) and fixed to vertical rack-mount crabs.

Determining the thickness of the drywall partition

Bearing in mind that the thickness of the structure depends on the width of the frame profile and the number of layers of drywall, which is used as a skin, we can conclude: as they are added, the overall rigidity of the structure increases. Before calculating the parameters of the partition, you need to determine its functional purpose.

Decorative structures that do not have a bearing purpose are made of a narrower profile and have a single layer coating. The need for additional communications (pipes, wiring) should also be taken into account when determining the required dimensions. According to the thickness of the drywall partitions, they are divided into three main categories:

- Partitions 75–150 mm. The thinnest are structures of type C111 with a profile width of 50 mm and a drywall thickness of 12.5 mm. The C112 double-layer skin adds another 25 mm.

- 150-175 mm. Type C113 is equipped with a frame made of PN-100 profile, and its two-sided three-layer coating forms a total thickness of 175 mm.

- 175–250 mm. The double frame of the C115 and C116 partitions, using the PN-75 and PN-100 profile, provides a total structure width of 200 and 250 mm.

Accordingly, the use of a profile with a width of 75 mm (PN-75) or 100 mm (PN-100) increases both the thickness of the structure and the required insulation layer. The standard width of the wooden beam of which some types of frames are made is 80 mm. The minimum thickness of such partitions depends on the number of plating layers and is 85 mm (single-layer C121) and 100 mm (two-layer C122).

Concluding the review, it should be noted that their classification by KNAUF specialists is basic and fundamental. Do you have any recommendations on the design of such structures based on personal experience? Do you want to ask questions about the planning and installation of drywall partitions? Our experts will be interested in any developments in the field of repair and decoration. And to help with a detailed answer to any question is our job!

1. Thin decorative or functional. It is built if the room is small and you need to save space. A single frame is made of a profile with a transverse size of 50 mm, the skin is double-sided single-layer (GKL thickness - 12.5).

In this case, the total size of the skin is 50 + 12.5 * 2 = 75 mm. 3. Increased soundproofing. To equip a part of the room under the bedroom and make it impervious to external noise, a thicker layer of absorbing material is laid in the frame.

- Partitions 75–150 mm. The thinnest are structures of type C111 with a profile width of 50 mm and a drywall thickness of 12.5 mm. The C112 double-layer skin adds another 25 mm.

- 150-175 mm. Type C113 is equipped with a frame made of PN-100 profile, and its two-sided three-layer coating forms a total thickness of 175 mm.

- 175–250 mm. The double frame of the C115 and C116 partitions, using the PN-75 and PN-100 profile, provides a total structure width of 200 and 250 mm.

Bearing in mind that the thickness of the structure depends on the width of the frame profile and the number of layers of drywall, which is used as a skin, we can conclude: as they are added, the overall rigidity of the structure increases. Before calculating the parameters of the partition, you need to determine its functional purpose.

- 12.5 cm: 10 cm PS - profile + thickness of 2 sheets on both sides. These are proven metrics.

- 7.4 cm: when using an arched PP profile (64 mm) + GCR thickness on each side. Such a partition is the thinnest in the combination of metal profile and drywall.

What does size affect?

Choosing a drywall sheet size is crucial because it reduces the amount of material used and the overall repair cost. Among the most important parameters, thickness occupies a special place, because the strength of GCR and, accordingly, the strength and capabilities of the structure itself depend on it in many respects. The thickness of the sheet should be selected, focusing on the type of planned work. Standard GKL for partitions has a thickness of 12.5 mm, it can withstand 50 kg of weight per square meter of sheet without voltage, however, the use of drywall fasteners is a prerequisite, and the load should not be shock type. Such sheets are used to form walls and decorative partitions.

If you plan to fix several shelves or wall cabinets, for example, kitchen or products for corner decor, then it is advisable to give preference to models with a larger thickness based on the following data:

- A drywall sheet of 14 mm withstands a load of 65 kg / sq. m

- A 16 mm plate can handle a weight of 75 kg per 1 square meter.

- Thickness 18-20 mm is used with a load of up to 90 kg / sq. m

- A 24 mm sheet accepts 110 kg / sq. m

If there are no thick sheets on sale, you can put the standard gypsum board in several overlap rows

This can be simpler and more economical, given the low availability of thick sheets in the free market.

It is important to consider the features of the room in which the repair work is carried out. If this is an apartment or a private house, then it is quite possible to do with thin sheets, since the owners of the room treat it carefully and are unlikely to deliberately inflict blows and mechanical damage

If we are talking about industrial facilities or warehouses, then the structural strength comes to the forefront from the point of view of safety, therefore, here, sheathing with sheets with a thickness of 14 mm and above is mandatory.

For the formation of interior structures, special GKL sheets of 6 mm thickness are used. They are distinguished by their ductility, they are well bent, therefore they are often used for the installation of wave-like elements of decor. But for the installation of arches, this thickness is not suitable, because it can not cope with the load. Preference should be given to denser sheets or to lay thin GCR in several layers.

If the owner of the room plans to hang paintings on the walls, then it is worth buying a sheet with a thickness of 10mm. To mount a plasma TV, it is better to stay on the thickest sheet. Otherwise, the structure may collapse, and the TV may break. If the wall will not be subjected to load, then in this situation it is enough to limit the GCR to 8 mm.

Drywall is similarly selected for leveling the ceiling and creating multi-level coatings. You need to know exactly what will be recorded in it, and what load will be per square meter of area. Experts recommend taking thin sheets with a thickness of 9.5 as a base point, they are lightweight, so they do not overload the floors. Such material can easily withstand built-in lamps located at a standard distance of 60 cm from each other.

Types of material

Drywall as a composite material has found application in the repair of a wide variety of rooms, with its help new designs are created, existing ones are improved and the structure of the room is changed thanks to extensions, walls and partitions. To properly use this material, you must be able to select it for a specific type of work.

There are several varieties of drywall:

Normal, which is labeled with the abbreviation GKL. Inside the product is gypsum dough, which is closed on both sides with thick cardboard. It is most convenient to use such sheets for interior decoration

It is important to use them where the humidity will not be increased, otherwise the material will swell and lose external qualities, which will affect the reliability of the entire structure. It is convenient and quick to work with sheets of this type; they are light, flexible and economical.

- Fire-resistant, which is called GKLO, is most favorable for use in non-residential premises, creating partitions. With it, you can protect the space from the threat of fire, which allows you to use it for fireplaces and stoves.

- Moisture-resistant, has the designation GKLV, it is used in rooms where the level of humidity is significantly increased, it is a kitchen and a bathroom. To ensure such properties, substances are added to ordinary drywall that help not absorb moisture, thereby preserving all the characteristics of the sheet. This option resists the formation of mold and fungus on its surface. If the rooms have too high a humidity level, it is recommended to use a different finish for them, because the plasterboard will begin to deteriorate due to excessive moisture.

- Fire-resistant, with the marking GKLVO, is distinguished by the presence of resistance to both fire and water.

If you need to build special building structures, then you can select additional types of material that have a different level of thickness, these are:

- arched variety with a thickness of 6.5 mm,

- ceiling, which has a thickness of 9.5 mm,

- the wall is the thickest variation, where the thickness is 12.5 mm.

The thinnest option is needed to create interesting curved structures both under the ceiling and as a wall. The ceiling type is well suited for leveling the surface of the ceiling or creating an interesting design with lighting on top of the room. The wall type is appropriate for leveling walls, and for interior partitions, which due to its thickness helps to achieve good sound insulation.

What determines the dimensions?

A standard drywall sheet has only one stable indicator, and all others can vary depending on the scope of its use. For the right choice of material, you need to understand which type is suitable for which work.

There are such varieties of GCR, such as:

- arched sheets

- reinforced

- perforated acoustic

- vinyl coated sheets.

Gypsum plasterboard acoustic sheets are best used for bulky rooms, such as classrooms or halls, which should have an acoustic effect. If we consider vinyl sheets, then their undoubted advantage will be the readiness of the material for use, no treatment is necessary on the surface. The scope of its use is narrower due to the inability of the material to breathe.

If the matter concerns the wall appearance of the product, it is necessary to exclude thin sheets, which in this case will be inappropriate. Only the use of 12 and 15 mm GKL will make it possible to build a reliable and strong wall.

Choosing options for future walls or piers in the bathroom: you can also use drywall for this room, using a moisture-resistant option, you can avoid getting wet and delaminating the material.

Knowing the types of products and their sizes allows you to choose the right material for repair. If you need to trim the whole room, then standard sheets will be the best choice. In the case when the walls of the room have a non-uniform height, it is more convenient to buy non-standard sheets, which are two times smaller in size. For places that will have to withstand heavy loads, the thickest type of product should be used.

When planning the manufacture of an interior partition, it is best to use the longest GCR, which can reach 4.8 m, which will significantly speed up the repair process and save on the purchase of excess materials.

For aesthetes, and those who want to make something unusual and beautiful in the house, they will need a designer type of gypsum board, which is also called arched due to the fact that its thickness is only 5, 6, sometimes 6.5 mm, it can be easily bent. In order for such a product not to burst due to loads, it contains two whole reinforcing layers.

If we talk about non-standard materials, then it is worth remembering about the sound insulation type from Knauf, which has increased hardness and, in addition to standard thickness indicators of 12.5 mm, there are 10 and 15 mm options.

The choice of product thickness is dictated by the location. Thin sheets are mounted on the ceiling so as not to overload the structure, medium and thick can be laid both on the walls and on the floor.To create original compositions, thin material is required, for wet rooms it is moisture resistant, and in the case of a contact with a strong heat source, fire-resistant drywall is required.

Types of Frame Partitions

A frame partition is a structure made of steel profile or a wooden beam, sheathed on both sides with sheets of drywall in one or several layers. To protect against excess noise, as well as for insulation purposes, its internal cavity is filled with insulating material. The German company KNAUF, a manufacturer of high-quality building materials, classifies interior drywall partitions according to several types, shown in the table below.

| Type of construction | main parameters | Main characteristics |

| C111 | The mass of 1 m3 is 28 kg, the height can reach up to 8.0 m. | The design is a single frame made of galvanized steel profile, which is sheathed on both sides with sheets of gypsum plasterboard - waterproof gypsum plasterboard - in one layer. Inside it is filled with heat and a sound insulator in the form of a mineral wool slab. It is used as an internal fence in rooms with low requirements for sound insulation and fire resistance. The minimum thickness of the plasterboard partition C111 depends on the width of the profile and sheets GK. |

| C112 | Mass 1 m3–53 kg, height from 4, 0 to 9.0 m. | A single metal frame has a two-layer sheathing with sheets of drywall on both sides. Filler - mineral wool. The type of construction provides higher sound insulation characteristics (RW index - up to 50 dB) and fire resistance (limit - 1.25 hours). It is used both in redevelopment and in capital construction. |

| C113 | The height can be up to 9.5 m. Mass 1m3 - about 78 kg. | The steel profile frame has a “single” design and is sheathed on both sides with sheets of waterproof drywall in three layers. Mineral wool, filling the "insides", in addition to protection from noise, perfectly saves heat. Due to the increase in the number of GCR layers, soundproofing properties increase. |

| C115.1. | Height - up to 6.5 m, weight 1 m3 - 57 kg. | It is equipped with a double frame made of steel profile, which is sheathed with two layers of drywall. Along with durability and excellent fire resistance, it has high soundproofing characteristics. The thickness of the drywall partition depends on the width of the profile used, but even its minimum values allow the design to be used both for repair and for new construction. |

| C115.2. | The mass of 1 m3 is 69 kg. Max. height 9.0 meters. | In addition to the two-layer cladding, the double frame is divided by an additional sheet of drywall (spaced frame). Due to this feature, the strength of the partition increases, as well as its noise and heat insulation properties. Inside is filled with slabs of mineral wool. |

| C116 | Height is from 4.5 to 6.5 m. Mass of 1 m3 is 61 kg. The minimum thickness of the C116 partition is 220 mm. | A feature of this design from a double metal frame, sheathed with GKL sheets in two layers, is the presence of space for communications. This type of partition provides the possibility of laying heating pipes, water pipes or sewers, as well as the hidden installation of electrical wiring. The fire resistance is 1.25 hours. Soundproofing index C116 is 50 dB. |

| C118 | Mass 1 m3 - 86 kg. Max. height - 9 m | Partition of the class "Protection of the premises from penetration." It is made according to type C113 with a single metal frame, sheathed with a three-layer drywall coating. A feature of the product are sheets of galvanized steel, 0.5 mm thick, inserted between the gypsum board, which significantly increases the strength and fire resistance of the structure. |

| C121 | Mass 1 m3 - 32 kg. Max. height 3.1 m. | The frame is made of wooden timber, which has a moisture content of 12% and is sheathed on both sides with one layer of drywall sheets. The minimum thickness of a drywall partition of type C121 depends on the width of the beam and the sheets of gypsum board. |

| C122 | The mass of 1 m3 is about 57 kg. Height 3.1 m. | It is distinguished by a two-layer “upholstery” of a wooden frame with sheets of drywall. The insulating material of the partition is a plate of mineral fiber. Advantages - high strength and good sound insulation. |

Drywall used in the design of partitions can be either ordinary, GKL grade, or waterproof (GKLV) or fireproof (GKLO). Practical application, most often, has a material in the form of sheets with a width of 12.5 mm. Regardless of their type and size, the surface can be finished in any way: painted, tiled, papered, etc.

What is the thickness of the drywall partition?

Absolutely in any apartment, drywall will be the way, the constructions made from it are relevant for expensive mansions and small apartments of the Soviet period such as “Khrushchev”.

The structures themselves, and most often these partitions can carry both a purely practical function of delimiting the room, and be part of the decor, taking on the aesthetic load.

What should be the thickness of the created partition? It all depends entirely on the desire of the owner and the budget.

As a rule, the usual rectangular partitions used to create separate zones in the apartment, or installed in the office, are made with a door, and therefore their thickness is determined by the thickness of the door block, this is more than enough.

If a partition is created without a door, but with a through passage, then its thickness corresponds to an arched or rectangular block.

If the aperture is a continuation of the partition, which is becoming more common recently, then the thickness of the partition depends entirely on the owner’s desire, however, it is worth remembering that the more massive the structure, the more complicated the frame and therefore higher costs.

In this video, watch a useful video tutorial on how to build a plasterboard partition with your own hands.

Which is better to choose and use drywall thickness

The material used for repair is divided into types. Each type is applicable for its intended purpose, but there are options when the finishing material is used in the wrong place.

The material used for repair is divided into types. Each type is applicable for its intended purpose, but there are options when the finishing material is used in the wrong place.

- Wall GCR. Suitable for leveling walls in the room. With its help create partitions, both decorative and capital interior buildings.

- Ceiling GKL. The main difference is the thickness. Thin sheets with less weight should be mounted on the ceiling.

- Arched type. Drywall with flexibility due to its thickness. It is applicable not only for creating arched openings, but also for the production of decorative curly elements on the surface, partitions, and ceiling. Sometimes a beautiful butterfly made of arched material is mounted at an angle between the ceiling and the wall.

- Moisture-proof - GKLV green tone.

- Refractory - GKLO pink color.

- Normal - GKL gray color.

- Moisture-resistant refractory - GKLVO red tone.

Depending on the purpose of the building material, a certain type is used.

What are the sizes of GCR

Each type of material has its own dimensions.

| No. p / p | Type of GCR | Manufacturing plant | Its width, length, mm | Area, m2 | Weight, kg |

| 1 | Wall | Knauf Lafarge | 1200-2500, 1200-2500 | 3 26 | |

| 2 | Ceiling mounted | 1200 to 3600 | 3 36 | ||

| 3 | Arched | 1200-2500 | 3 | 17.1 |

What is the thickness of GCR - such a weight. Each manufacturer creates assembly sheets in sizes that differ from the standard in millimeters.

What is the thickness of the sheet

For cladding surfaces using a material of 12.5 mm. This sheet will withstand a certain load.

For cladding surfaces using a material of 12.5 mm. This sheet will withstand a certain load.

Drywall 15-24 mm is used for covering the surface on which heavy objects will be hung - a TV, shelves with books, a water heater.

Wall sheets, regardless of type (normal, moisture resistant) have a thickness of 12.5 mm.

The ceiling view has a thickness of 9.5 mm.

Arch GKL - 6.5 mm.

Sometimes, when constructing a capital partition, double wall cladding is used. This is created for the strength of a structure that can withstand heavy weight.

What width is better to choose

All types of drywall have the same width - 1200 mm. Under the GCR, a frame base of profiles is mounted, in which there are exact dimensions for fixing the profile. This applies to both the ceiling and other surfaces.

All types of drywall have the same width - 1200 mm. Under the GCR, a frame base of profiles is mounted, in which there are exact dimensions for fixing the profile. This applies to both the ceiling and other surfaces.

If you need a smaller drywall, it is cut with a construction knife, a milling cutter.